Traditionally, printed circuit board (PCB) designers using Cadence Design Systems tools operated in a silo, isolated from the mechanical design team working with tools like Autodesk Fusion. Teams would play a game of digital ping-pong, tossing files over the virtual wall, hoping everything gets noticed in the right place, at the right time, and by the right people.

This week at Autodesk University, we were excited to announce our new partnership with Cadence Design Systems, the leader in electronic systems design tools, which aims to bridge this gap between electronic and mechanical design teams. The integration connects specialized Cadence PCB technologies directly with Autodesk Fusion, advancing its powerful CAD, CAM, and PCB design capabilities to streamline ECAD to MCAD workflows and transform smart product design.

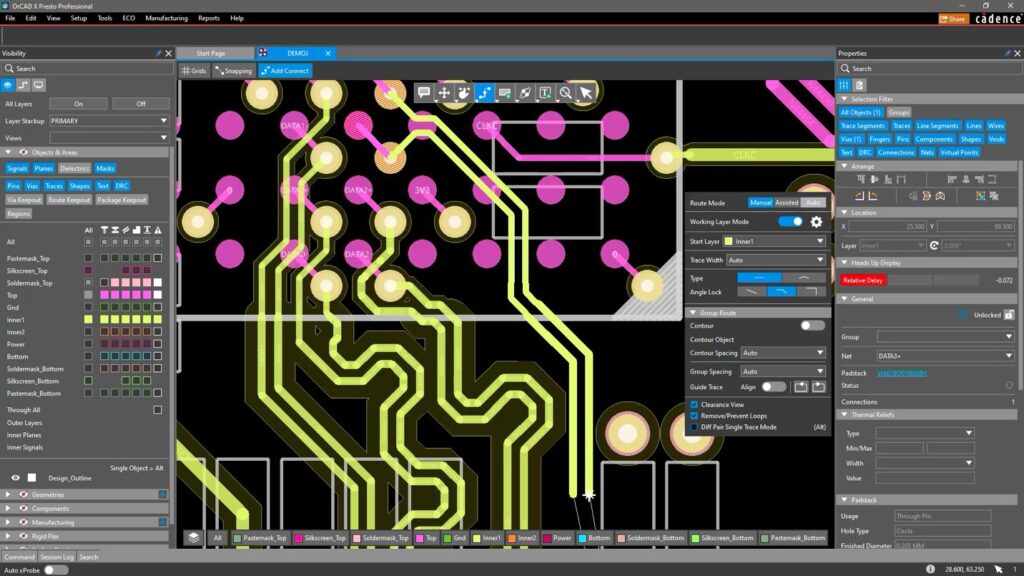

Together, the partnership brings cloud-based integration between Fusion and Cadence Allegro X and OrCAD X. The integrated solution is another example of Autodesk’s commitment to an open ecosystem and to improve collaboration across electronics and mechanical design teams.

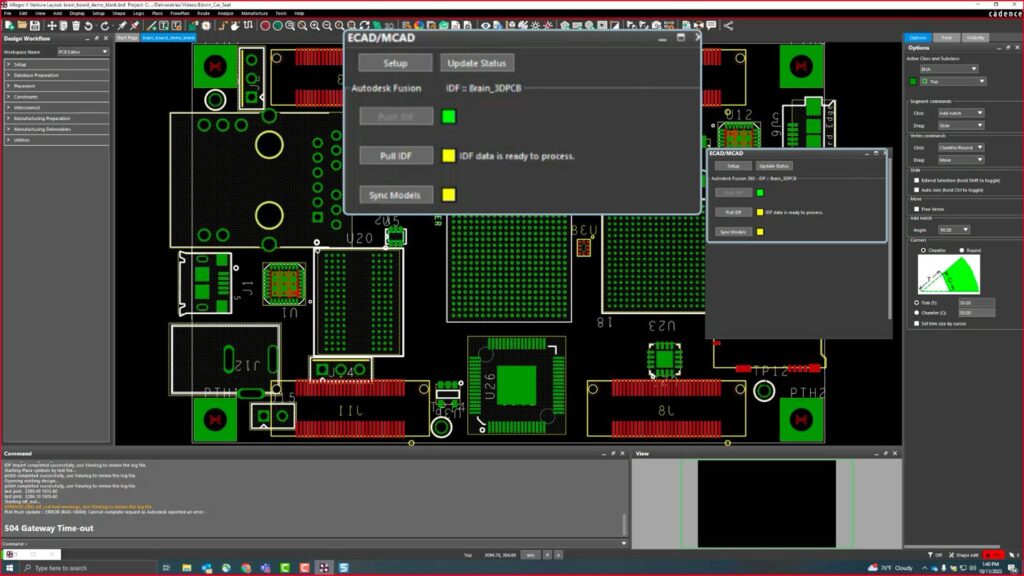

Your new electromechanical workflow with Autodesk Fusion and Cadence Allegro X and OrCAD X

Picture this: You’re working on a complex, high-speed PCB layout for a new wearable tech device. Mechanical housing has tight constraints, and thermal management is a crucial concern. With the integration between Autodesk Fusion and Allegro X, you don’t have to work blindly.

You can view the mechanical context in real time, ensuring your electronic components don’t clash with mechanical parts. This 3D visualization is not just a static representation either—it’s an interactive model that informs design decisions at every turn.

When you adjust a component in the PCB layout, the changes are dynamically reflected in the mechanical model, and vice versa. When the mechanical team tweaks the housing to accommodate a new battery size, the updates are pushed instantaneously. No more missed emails or outdated file versions. You can now work in lockstep.

The need for constant file exports and imports is eliminated. It’s all about better coordinated and synchronized product design and development, reinforcing Autodesk’s philosophy of connected design-to-manufacturing processes and Cadence’s commitment to electronic design excellence.

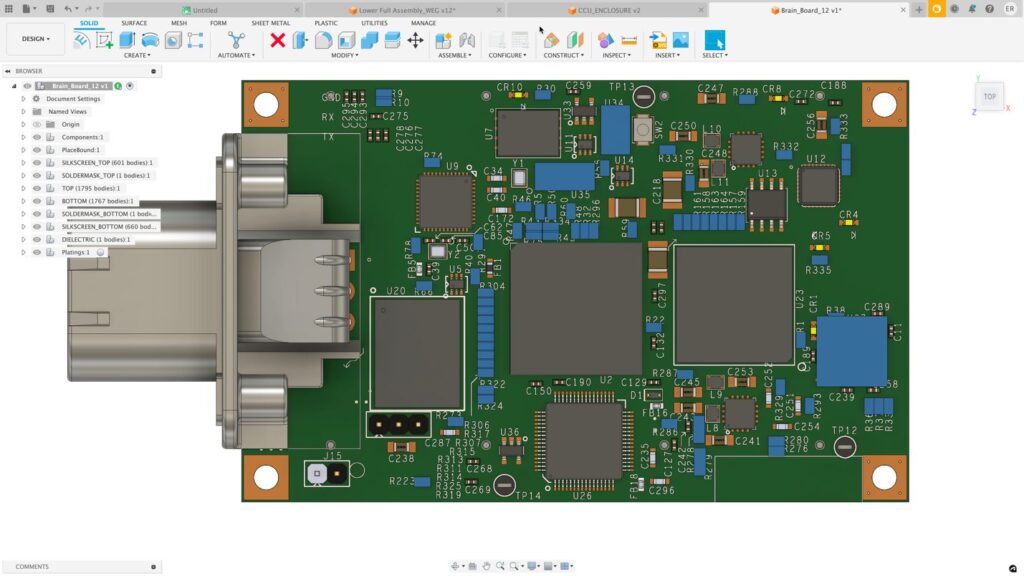

Electromechanical components are no longer static but intelligent, with metadata that carries through the entire design process. Clearance checks, thermal simulations, and even material selections are all integrated. This is not just about making components fit together; it’s about making them work together in the most optimized way possible.

“Tech is a fast-moving industry. In our field, we need to act fast and iterate for our clients on product designs without compromising quality. We are continually challenged to figure out how to efficiently send design information and share data between mechanical and electronic engineers. Typical mechanical and electronic design tools aren’t compatible with one another, requiring our team to manually ensure that data is in sync for each revision. While we’re careful with each round of communications, any manual process like that will be prone to errors.

Autodesk and Cadence Design Systems working together to deliver a direct connection between tools is exciting to us and a real game changer. Their solution would link engineers and enable them to work on a single design eliminating the need for manual translation of data, emailing, or messaging back and forth whenever a design was updated. This would streamline our processes, minimize errors, improve design quality, and reduce turnaround time for our clients.”

—Tyler Berryman, Product Design Engineer, Brash, Inc.1

Key benefits of this unified design ecosystem

Let’s delve into five high-level benefits this integration brings to the table for designers, engineers, and companies.

1. Remote collaboration

In today’s global environment, many teams work remotely—often in different time zones. This integration makes location irrelevant between mechanical and electronics engineers. Real-time, cloud-based collaboration and version control mean that an engineer in Germany can work on mechanical aspects while an engineer in the US handles electronics.

2. Customization and extensibility

Autodesk Fusion and Cadence PCB design tools are designed with extensibility in mind. Customization tools and workflows can be developed through APIs and scripting to fit unique project needs. You can even automate routine clearance checks to save hours of manual review.

3. Agile rapid prototyping

The combined strength of Fusion and Allegro X/OrCAD X empowers rapid prototyping at its finest. Teams can iterate quickly leveraging advanced features from both tools. For example, the simulation tools in Fusion allow you to conduct stress analysis and thermal modeling without ever leaving the CAD environment. When satisfied, you can push a prototype to production, knowing that the mechanical and electrical designs are already validated against each other.

4. Cost Efficiency

Let’s talk numbers for a moment. Reducing the design cycle means less time to market and lower labor costs. Moreover, catching design conflicts early avoids the exorbitant costs of rework, not to mention the potential savings in material costs by optimizing the design for both form and function.

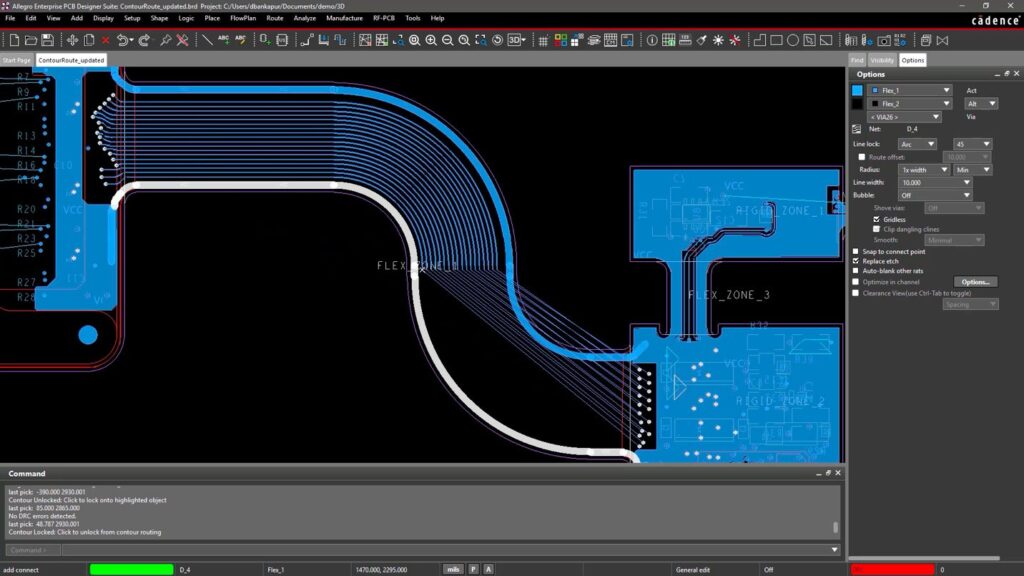

5. A seamless transition from design to production

The journey from concept to production can be fraught with pitfalls. However, this integration is a beacon guiding the way. Autodesk Fusion’s capabilities in CAM and CAD, merged with Cadence’s PCB design expertise, streamlines the transition. Manufacturability checks have become a proactive step, not a post-design afterthought.

For instance, when designing a PCB, you can anticipate and circumvent manufacturing issues such as acid traps or solder mask slivers in Allegro while concurrently ensuring that the board’s architecture does not introduce mechanical stresses in the final assembly—a concern that Fusion helps alleviate.

More than the sum of its parts

The partnership between Autodesk and Cadence is more than a mere collaboration. It’s a fusion of visions, technology, and innovation that propels the entire product design industry forward. It blurs boundaries between disciplines, fostering an environment where creating the next groundbreaking product is a journey of shared expertise and integrated effort.

“The shift toward remote collaboration, supply chain interruptions, and the ever-increasing customer demands for higher performing, personalized, and sustainable products are forcing companies to reevaluate how they work,” says Jeff Kinder, Executive VP, Product Development and Manufacturing. “The connection between Autodesk Fusion and Cadence Allegro X and OrCAD X, leveraging Autodesk’s Fusion Industry Cloud capabilities, puts the customer’s data at the center and facilitates a more seamless collaboration between electronic and product designers, reducing manual collaboration processes and allowing more time for innovation to meet customer demands.”

The need for cohesive design between electronics and mechanics will only grow as we move toward more complex and smart devices. This partnership supports the current market and paves the way for the future of design.

- Brash Product Development helps startups bring products to market. For all inquiries about Brash, Inc., please contact Michelle Riccetto, Marketing Director of Brash Inc., at: michelle@brashinc.com.” ↩︎