Autodesk Fusion 360 is a leading product development solution for global teams. What makes it the solution today and for the future of design and manufacturing is the sum of its parts — CAD, CAM, CAE, electronics design, collaboration, data management, and more. Let’s dive into why it’s time for you to make the switch.

Why Autodesk Fusion 360?

- Integrated design and manufacturing: Fusion 360 provides a comprehensive platform that integrates design, engineering, and manufacturing workflows seamlessly. Fusion 360 enables a streamlined and efficient design-to-manufacturing process from concept development to prototyping and production.

- Cloud-based collaboration: Fusion 360 operates on a cloud-based platform, allowing for seamless collaboration and data management. With real-time collaboration tools, teams can collaborate on projects, share designs, and access files from anywhere. This ultimately fosters teamwork and enhances productivity.

- Parametric modeling: The parametric modeling capabilities in Fusion 360 offer a powerful approach to design. By defining parameters and relationships, you can easily modify designs, make iterative changes, and update associated components and assemblies. The result – saving time and effort in design iterations.

- Versatile design tools: Fusion 360 offers a wide range of tools for 3D modeling, sketching, surface modeling, sheet metal design, and more. With advanced features like generative design, mesh modeling, and simulation, you can explore innovative design possibilities and optimize your designs for performance and efficiency.

- Extensive resource library: Fusion 360 provides access to a vast resource library that includes tutorials, webinars, forums, and learning materials. Whether a beginner or an advanced user, you can find valuable resources to enhance your skills, learn new techniques, and stay updated with the latest industry trends.

Fusion 360 empowers users to bring their design ideas to life, foster collaboration, and drive innovation in their projects. For an in-depth look at the differences between Fusion 360 vs. Solidworks, see here.

“What I loved about Fusion 360 was that it enabled me to conceptualize some of my ideas, create 3D models, and even 3D print parts to see if the components could be manufactured, fit together, and ultimately work as an assembly.” – Phil Law, PEMBREE Ltd

Autodesk Fusion 360: Integrated design and manufacturing

Fusion 360 is a powerful product development software tool that integrates design and manufacturing processes seamlessly. This integration brings numerous benefits to your workflow, ensuring a smooth transition from design to the production stage. Let’s take a look at the critical aspects of the integrated design and manufacturing capabilities in Fusion 360.

Seamless transition from design to manufacturing

With Fusion 360, you can seamlessly transition your designs from the virtual to the physical realm. The software provides comprehensive tools and workflows for manufacturing-ready models. These include generating toolpaths for CNC machining, creating 3D prints, or exporting files for other production methods. By working within a single software environment, you can eliminate the need for data conversions, reduce errors, and save time in the design-to-manufacturing process.

Five essential tools

To ensure a seamless transition from design to manufacturing in Fusion 360, here are five tools you need to know:

- CAM (Computer-Aided Manufacturing): The CAM functionality in Fusion 360 allows you to generate toolpaths for CNC machining. You can define cutting strategies, specify machining operations, and simulate the manufacturing process to ensure optimal results. By utilizing CAM, you can directly translate your design into machine instructions, streamlining the manufacturing workflow.

- Drawing and documentation: Fusion 360 provides powerful tools for creating detailed engineering drawings and documentation. You can generate 2D drawings with precise dimensions, annotations, and views, facilitating clear communication with manufacturers and ensuring accurate production of your design.

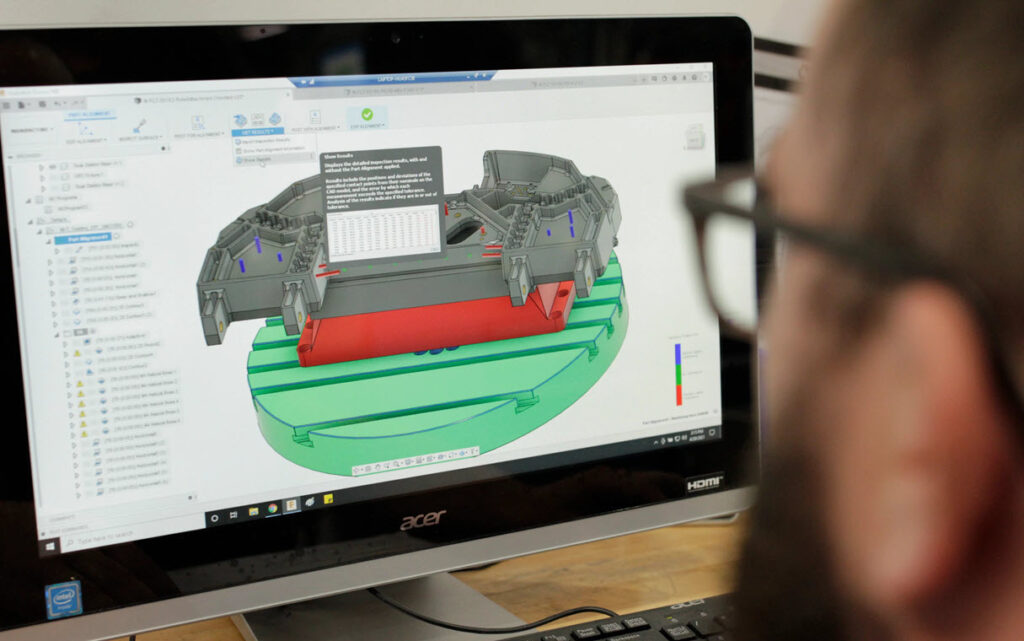

- Design for Manufacturability (DFM) Analysis: Fusion 360 offers DFM analysis tools that help you optimize your design for efficient manufacturing. These tools identify potential manufacturing issues, such as undercuts, tight tolerances, or areas difficult to machine. This enables you to make necessary design modifications early in the process.

- Design validation and simulation: The simulation capabilities in Fusion 360 allow you to analyze and validate your design for its performance under different conditions. You can simulate mechanical stress, thermal behavior, and other factors to ensure your design can withstand real-world operating conditions. By conducting simulations, you can make informed decisions to optimize your design before moving into production.

- Additive manufacturing (3D Printing): Fusion 360 supports additive manufacturing processes, allowing you to create 3D printable models. You can prepare and optimize your design for 3D printing, including generating support structures, specifying print settings, and exporting files in the appropriate format for additive manufacturing technologies.

What others have to say

“We found with almost the click of a button, Fusion 360 is capable of exporting our 3D models to our CNC machine to manufacture right then and there, ending up with a finished part that is ready to hit the racetrack or ship out the door to our client.”

– Betim Berisha, Co-Founder BBi Autosport

Factors to consider

Design optimization and iteration

Fusion 360 enables users to perform design optimization and iteration, allowing for fine-tuning of their models for improved manufacturing outcomes. By leveraging tools like parametric modeling, simulation, and generative design, users can explore different design alternatives, evaluate their performance, and optimize them for manufacturability. This iterative process helps in refining designs, reducing material waste, and enhancing the efficiency of the manufacturing process.

Design documentation and communication

Fusion 360 offers robust tools for creating design documentation and facilitating effective communication throughout the design-to-manufacturing process. Users can generate detailed drawings, annotations, and bills of materials (BOM) directly from their 3D models. Additionally, Fusion 360 provides collaboration features that enable seamless communication and sharing of designs with team members, clients, or manufacturing partners. Clear and accurate design documentation, combined with efficient communication, streamlines the manufacturing process and ensures that everyone involved has access to the necessary information for successful production.

Ready to get started with Autodesk Fusion 360?

Start your journey today with a free 30-day trial.

Comprehensive Getting Started Guide

- Welcome to Autodesk Fusion 360: Guide to Getting Started

- Autodesk Fusion 360 Basics: Getting Started with Sketching

- Autodesk Fusion 360 Basics: 3D Modeling Made Easy

- Autodesk Fusion 360 Basics: The Fundamentals of Assemblies

- Autodesk Fusion 360 Basics: Manufacturing Fundamentals

- Autodesk Fusion 360 Basics: Simulation Tools for Everyone

- Autodesk Fusion 360 Basics: Collaboration and Data Management

- Autodesk Fusion 360 Basics: Library Features, Tools, and More