In the rapidly evolving arena of product development, manufacturers are perpetually on the hunt for methods to expedite processes and augment efficiency. A pioneering methodology causing a stir in this domain is Computer-Aided Engineering (CAE). CAE is a groundbreaking technology that assists engineers in simulating and authenticating product designs prior to manufacturing, thereby curtailing time-to-market, economizing costs, and fortifying product quality.

One pivotal advancement in the CAE landscape is the integration of these tools within the product development process. This integration facilitates a smoother transition between design, analysis, and manufacturing stages, reducing the effort and time typically associated with these transitions.

Autodesk Fusion as a symbol for integration

Autodesk Fusion is a prime example of software that epitomizes this integration. Fusion is a cloud-based 3D CAD, CAM, CAE, PCB and data management tool that integrates industrial design, simulation, collaboration, and machining. It’s a comprehensive solution for product development, fostering team synergy across design, engineering, and manufacturing.

Fusion amplifies CAE by allowing engineers to simulate their designs within the same environment they were conceived. This obviates the need to alternate between different software tools, substantially reducing errors and conserving precious time. Engineers can conduct structural, thermal, and modal analyses, among others, right within the design tool.

Real-world performance

Fusion’s Computer-Aided Engineering (CAE) capabilities provide engineers with an extensive toolset for simulation that goes beyond basic performance checks. This includes the ability to analyze part performance, assess manufacturability, and explore generative design capabilities, all within a single platform. Generative design, a key component of Fusion’s CAE capabilities, can aid in discovering weight reduction opportunities and performance enhancements, contributing to the development of more efficient and high-performing products.

Fusion’s CAE suite encompasses a variety of simulation study types, including but not limited to, structural, thermal, and explicit simulations. Structural simulations allow engineers to evaluate the strength and durability of their designs under various loads, crucial for determining a design’s ability to withstand real-world stresses. Thermal simulations provide the ability to analyze how different heat and cooling conditions would impact the design, essential in industries where temperature changes can affect product performance. Explicit simulations are particularly useful for studying the effects of short, severe load cases like impacts and crashes, thus ensuring the product’s reliability under extreme conditions.

Furthermore, Fusion’s CAE capabilities also extend to machine simulation. Engineers can use this feature to simulate and optimize toolpaths on a machine’s digital twin, enhancing manufacturing processes. Fusion aids in preventing potential manufacturing errors by ensuring toolpaths are safe and accurate.

Enhanced Collaboration

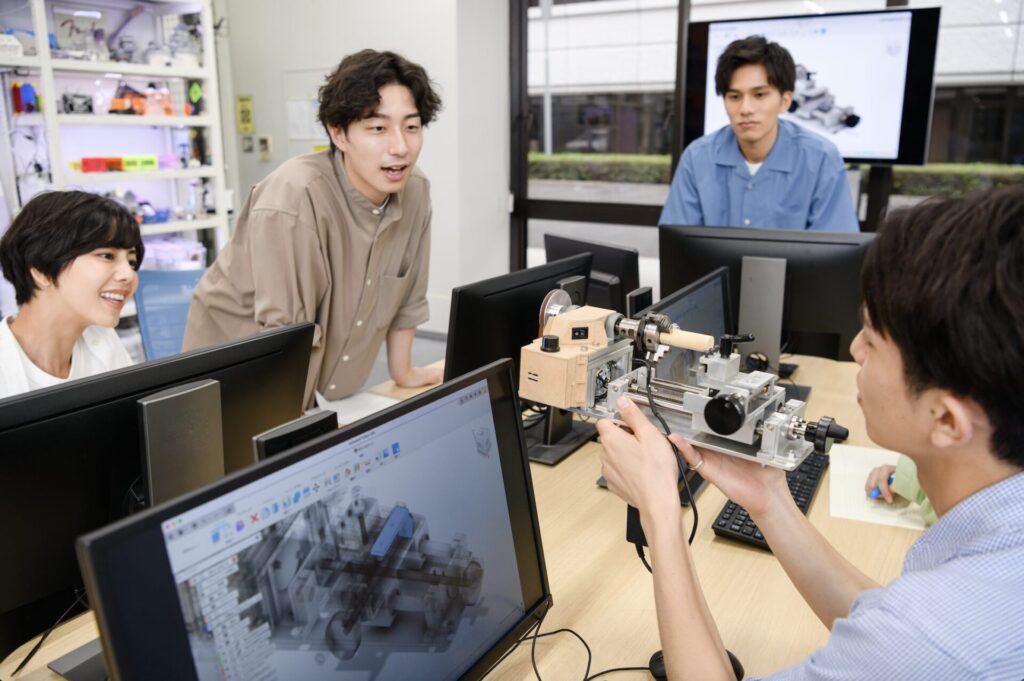

The cloud-based characteristic of Fusion boosts collaboration among team members. Irrespective of their location, team members can access designs and simulations, amplifying efficiency and fostering improved communication. Engineers can effortlessly share their designs, garner feedback, and implement modifications in real-time, nurturing a collaborative atmosphere that spurs innovation.

In addition to enhanced collaboration, Fusion empowers engineers to broaden their expertise. Traditionally, engineers might have specialized in a single domain, but with Fusion, they can venture into new areas like manufacturing or electronics design, becoming jacks-of-all-trades. This flexibility not only makes them more versatile but also allows for more holistic design and problem-solving approaches.

The expansion of the consumer products industry, in particular, underscores the importance of this cross-disciplinary understanding. Mechanical and electronics engineers need to work in harmony to meet the demands of this burgeoning field. Fusion’s ability to bridge these two disciplines fosters seamless communication, enabling the creation of specially tailored solutions. For instance, mechanical and electronics engineers can collaborate to create innovative smart collars for the expanding wearable tech market. This kind of synergy is the future of engineering, and Fusion is at the forefront of facilitating this shift.

Fostering innovation

Possibly one of the most substantial benefits of Fusion’s integrated approach is its influence on innovation. By offering a single, unified platform for the entire product development process, Fusion allows teams to iterate more swiftly, explore more design alternatives, and eventually create superior products. This integrated approach eliminates obstacles that can hamper creativity, empowering designers and engineers to push the envelope of what’s feasible.

The incorporation of CAE tools into the product development process, as exemplified by Fusion, signifies a considerable leap in the field of engineering. This approach enables companies to streamline their design processes, enhance product quality, and stimulate innovation. In today’s accelerated manufacturing landscape, securing these competitive advantages is more crucial than ever. As we gaze into the future, it’s evident that integrated tools like Fusion will continue to sculpt the landscape of product development and manufacturing.