This post is also available in: Français (French) Italiano (Italian) Deutsch (German) 日本語 (Japanese)

The Autodesk Fusion industry cloud represents a new era of connected data and collaboration to design and make anything. Read on to learn what the future holds.

The landscape of product development is transforming, driven by the integration of cutting-edge technologies – transforming the way products are conceptualized, designed, manufactured, and brought to market.

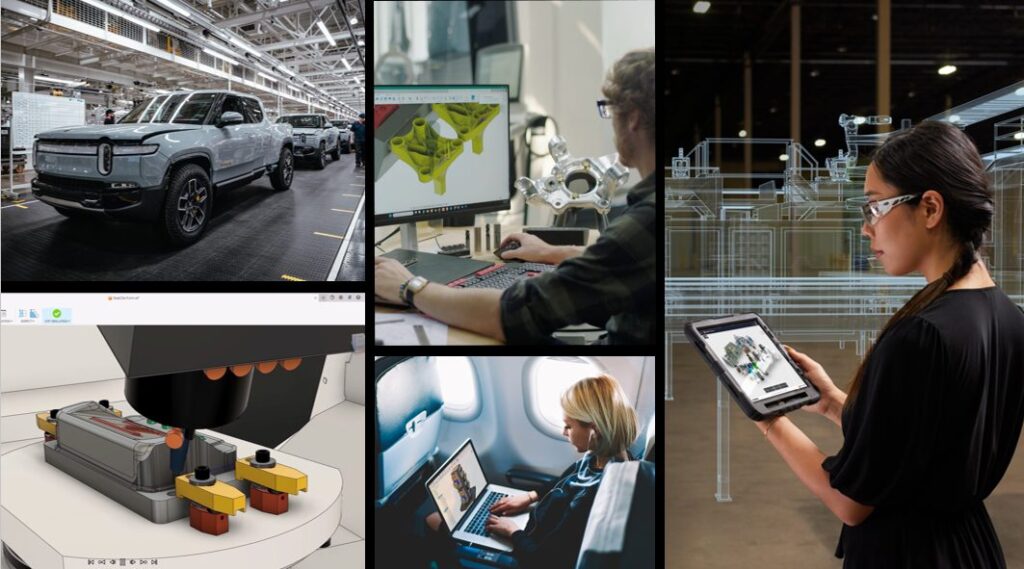

Rivian’s approach to breaking down silos in product development serves as a prime example of how innovation and efficiency can be achieved through seamless integration. Let’s take a look at how Autodesk Fusion industry cloud can help you gain a competitive advantage.

Breaking down siloes with Autodesk Fusion industry cloud

The development of Autodesk Fusion industry cloud embodies the industry-wide shift towards unified data and technology platforms. This platform connects the entire product development process, from design to manufacturing. By leveraging the power of connect processes, generative AI, and cloud-based data unification, Autodesk Fusion stands at the forefront of technological evolution. It’s not just a tool but an ecosystem that spans Autodesk’s extensive portfolio.

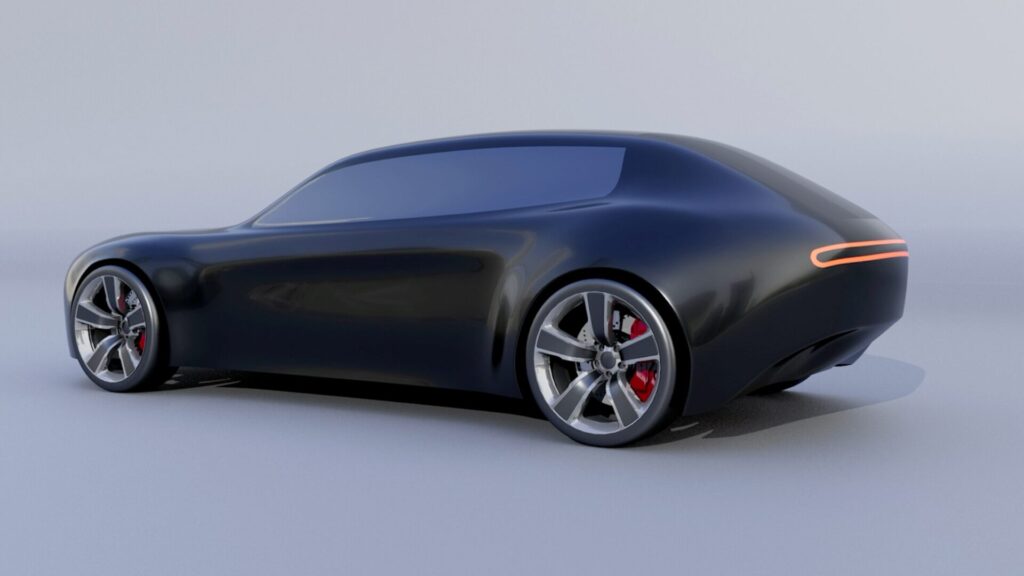

Innovations in design with Blank.AI

A key component of this transformation is the acquisition of Blank.AI, a generative AI technology that enhances industrial design creativity. By analyzing a company’s historical design data, Blank.AI aids in creating new concepts that align with brand identity and styling cues. Combined with existing Autodesk tools like ALIAS and VRED, this technology offers an immersive, collaborative design experience, bridging the gap between ideation and final product development.

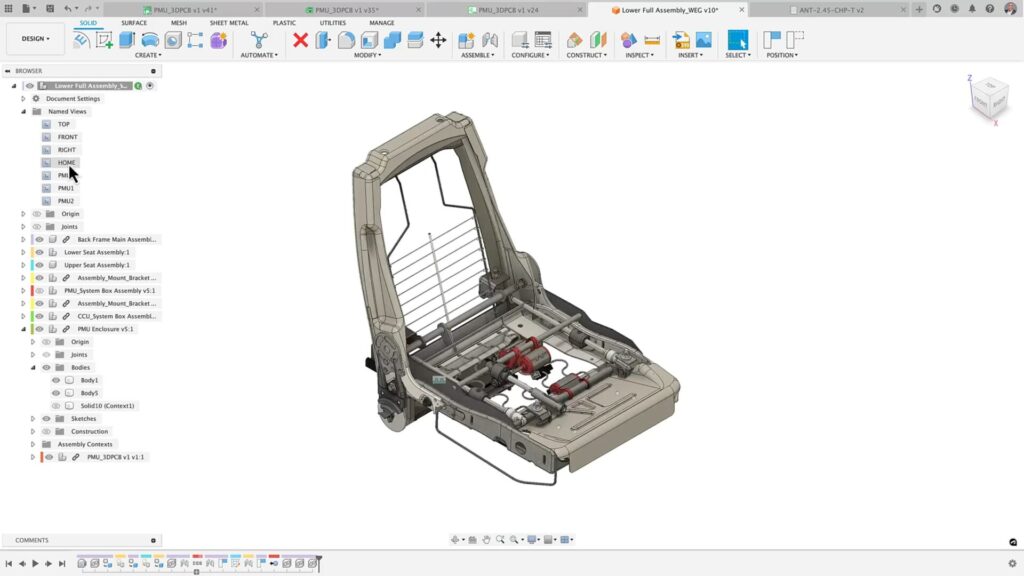

Enhancing engineering productivity

In the realm of engineering, the focus shifts to collaboration and agility. Fusion’s configurations are intuitively designed to integrate workflows across domains, such as design, simulation, and manufacturing. This approach ensures that multidisciplinary teams can collaborate effectively, maintaining a ”single source of truth” for projects.

Electronics engineering and manufacturing

Recognizing the increasing complexity of products, like those in the automotive and aerospace industries, Fusion now incorporates comprehensive electronics toolsets. These toolsets streamline the process from schematics to package design, offering a unified development experience. Partnerships with industry leaders like Ansys and Cadence further enrich these capabilities, allowing for real-time analysis and seamless integration of various design tools.

Generative automation in product development

Addressing time-consuming tasks such as 2D documentation, Fusion employs generative automation to streamline the creation of drawings from 3D models. This automation conforms to standards and offers a variety of dimensioning styles, significantly reducing manual effort.

Autodesk Fusion industry cloud – The future of manufacturing

In the manufacturing sector, Autodesk Fusion introduces advanced multi-axis machining workflows and partnerships with companies like CloudNC. These advancements utilize AI for automating toolpath creation, drastically reducing programming times and enhancing shop floor productivity.

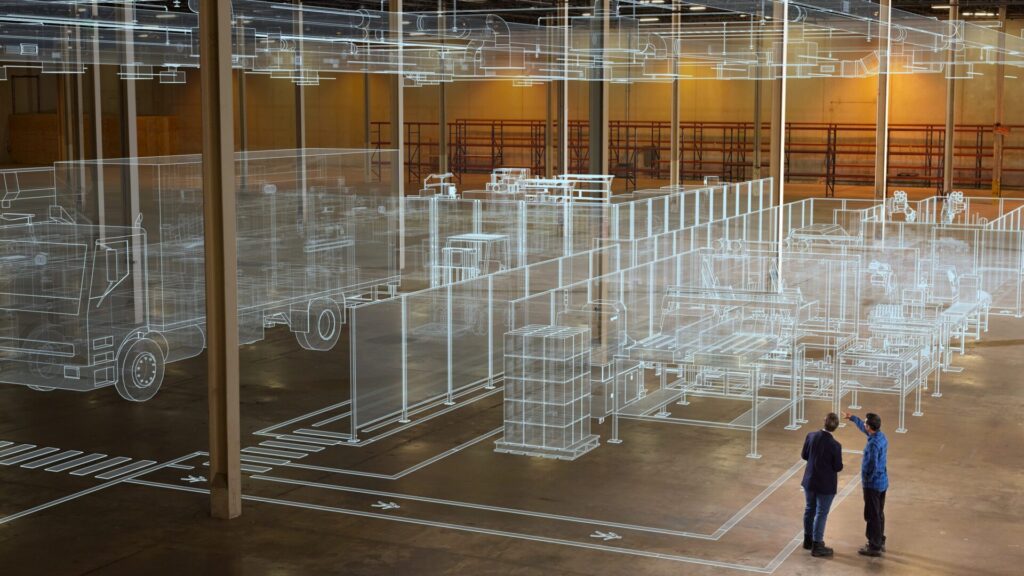

Towards a connected digital factory

The acquisition of FlexSim marks a significant step in achieving a connected digital factory. FlexSim enables real-time simulation and analysis of factory resource flows, identifying bottlenecks and improving overall efficiency. The integration of FlexSim within Fusion will connect it to the entire Autodesk Design and Make platform, providing a comprehensive suite of tools for digital factory management.

Autodesk Fusion industry cloud, revolutionizing design and manufacturing

The strides made by Autodesk in revolutionizing product development are just the beginning. With a focus on accessibility and versatility, Autodesk’s solutions cater to various manufacturing environments, from small workshops to large-scale production facilities. The future envisioned by Autodesk is one where digital technology powers and transforms the manufacturing process, making it more agile, resilient, and forward-looking.