Join us as we look back on an eventful year, highlighting key product announcements and innovative features in our Fusion 2024 Year in Review.

Table of Contents

- Cloud Data and Collaboration

- Design

- Electronics

- Manufacturing

- Thank You for a Fantastic Year

- Shape the Future of Fusion

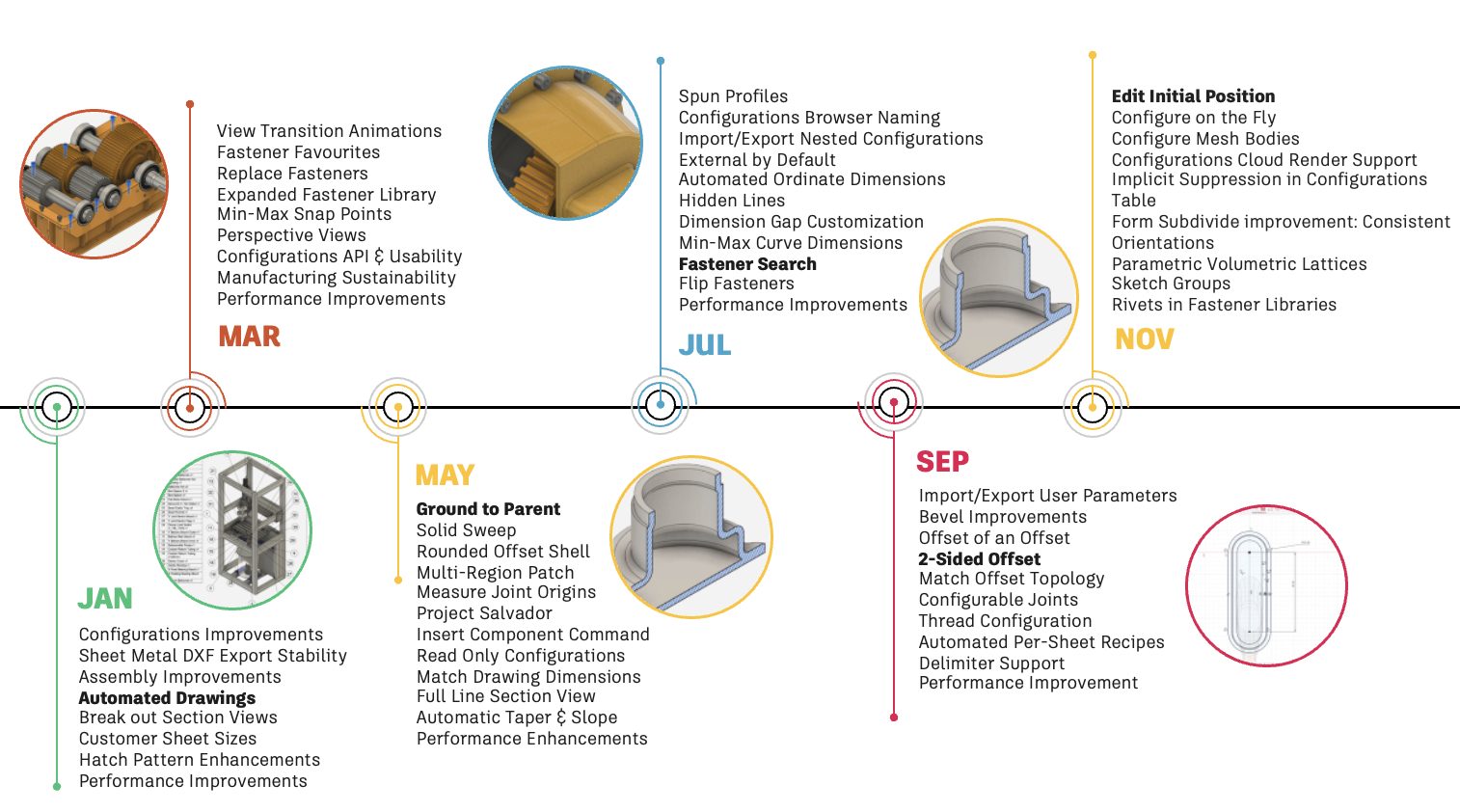

As we say goodbye to 2024 and hello to 2025, we wanted to reflect on the remarkable journey we’ve had with Fusion over this past year. From fantastic new features, enhancements in AI and Automation, major project announcements, incredible performance improvements and more we have so much to celebrate together.

Let’s take a look back at some of the advancements we made this year throughout our 6 major updates.

Cloud Data and Collaboration

Data powers collaboration, automation, and insights on all projects, and it is the cornerstone of our approach to unify CAD, CAM, CAE, PCB, PDM, and PLM. In 2024, we continued to evolve Fusion’s capabilities and user experience to offer more flexible and scalable support for your teams and external collaborators. Let’s explore some specific updates and enhancements we’ve introduced to elevate your collaboration and efficiency over the past year.

Bill of Materials

Back in March, we embarked on our Bill of Materials (BOM) journey. The addition of BOM allows you to manage and share detailed lists of items that make up a product, including part numbers, quantities, descriptions, and lifecycle states. Available in both the design environment and the Fusion web experience, this capability allows for real-time updates as models evolve, ensuring all stakeholders have access to consistent product data.

Learn more about Bill of Materials.

Configurable Item Numbering Scheme (Manage Extension)

This past October, we expanded the Manage Extension to include number generation capabilities beyond the predefined schemes, enabling hub administrators to define new numbering schemes that reflect company standards. This flexibility makes it easier to adopt the automated numbering feature of the Manage Extension as a normal part of the product development process.

New schemes creation is straightforward, providing tools to model the various segments of the schemes including prefixes, delimiters, sequencers, and suffixes. Administrators will also find additional settings, like an option to pick the default and a toggle to activate a scheme, making scheme management easier than ever.

Learn more about Configurable Item Numbering Scheme.

Improved Collaboration for Teams With New and Enhanced Projects

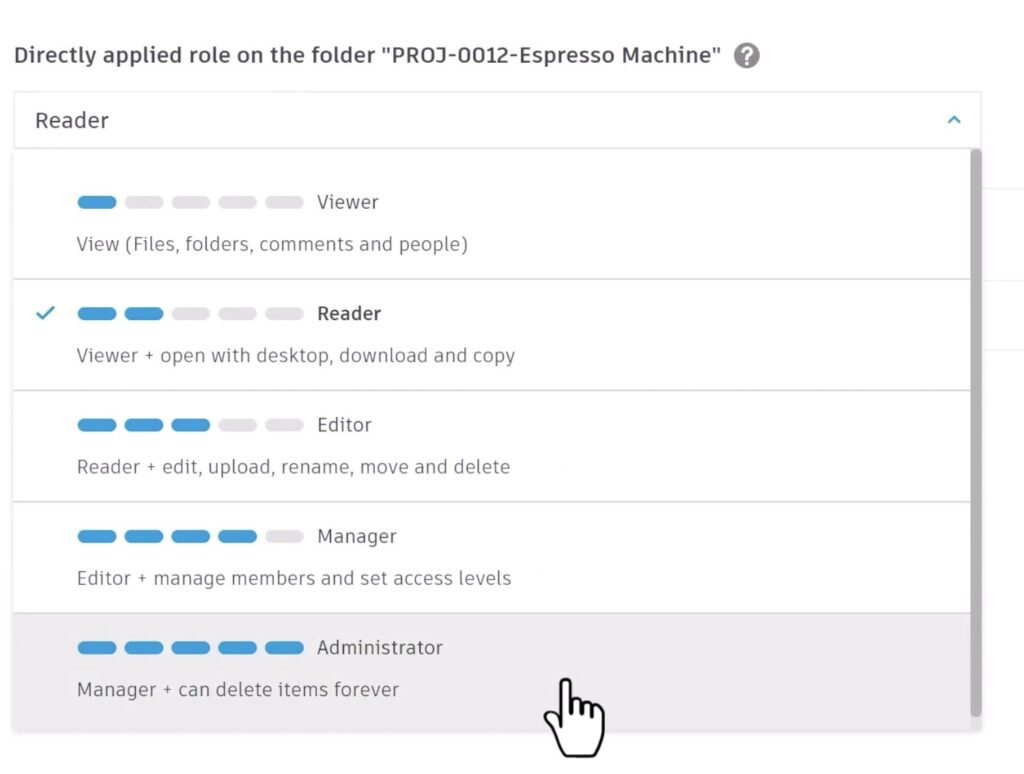

Recent enhancements to Autodesk Fusion projects introduce more granular controls, new and enhanced roles, and group management, offering teams greater flexibility and tailored control over design data. The changes include the ability to assign roles at the project, folder, and subfolder levels, improved and new roles such as Viewer, Reader, and Manager, and the ability to manage members through groups.

These features allow for more precise access control so that team members have the appropriate level of access to protect important data while facilitating collaboration. This is particularly important for efficiently managing large teams, collaborating with suppliers and subcontractors, and supporting classroom instruction, as it helps maintain accuracy, prevent unintentional modifications, and streamline the management of user permissions.

Learn more about the update to Projects.

Navigation and Search Enhancements

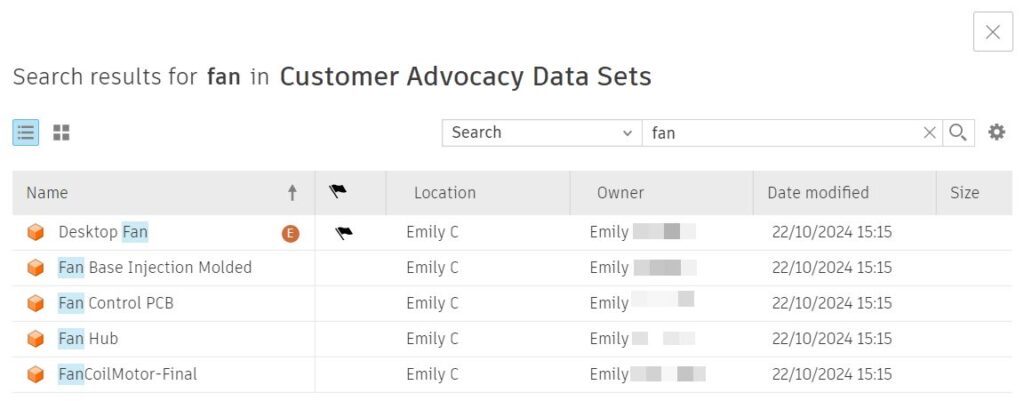

We have also significantly enhanced the user experience in Fusion with a range of new features designed to improve file navigation and search capabilities.

We introduced better navigation with filtering options, allowing you to discover files faster by filtering by time or file type. Additionally, an improved search experience within Fusion Home now enables you to effortlessly locate files by name, providing a comprehensive overview of potential matches to streamline file retrieval.

Not only that, we also added a new “Show in Location” option in the Home tab which allows you to navigate directly to the file’s location within the project and folder structure. You can also now select the scope of their search in the Home tab, limiting it to the current project or folder, helping you make more targeted and efficient searches.

Advancements in API

API enhancements for Fusion provide developers with more robust tools and greater flexibility, to create more powerful and customized integrations and automations within your workflows. This past year we worked to provide you with tons of new functionality, including support for Spun Profiles in Sketch, Read and write API support for Configurations, support for Thumbnail Creation and so much more.

Learn more about the Fusion API.

Prioritizing Performance

Each update, we’ve been focused on making continuous productivity improvements in different areas, from Electronics, Mechanical Engineering, Industrial Design, all the way through to Manufacturing so that you can realize the benefits of a connected, end-to-end, design and make process. In line with evolving industry demands, we’ve dramatically increased Fusion’s performance across every workspace, some of the areas where you will see significant enhancement include Upload, Mirror, Open, Save, and Extrude.

Design

This year, we’ve pushed the boundaries of design to bring you cutting-edge solutions. Let’s take a look at some of the advancements we’ve made this year.

Assembly enhancements

You asked for better assembly tools in Fusion, and we’ve been working diligently this past year to make your workflows smoother and more intuitive.

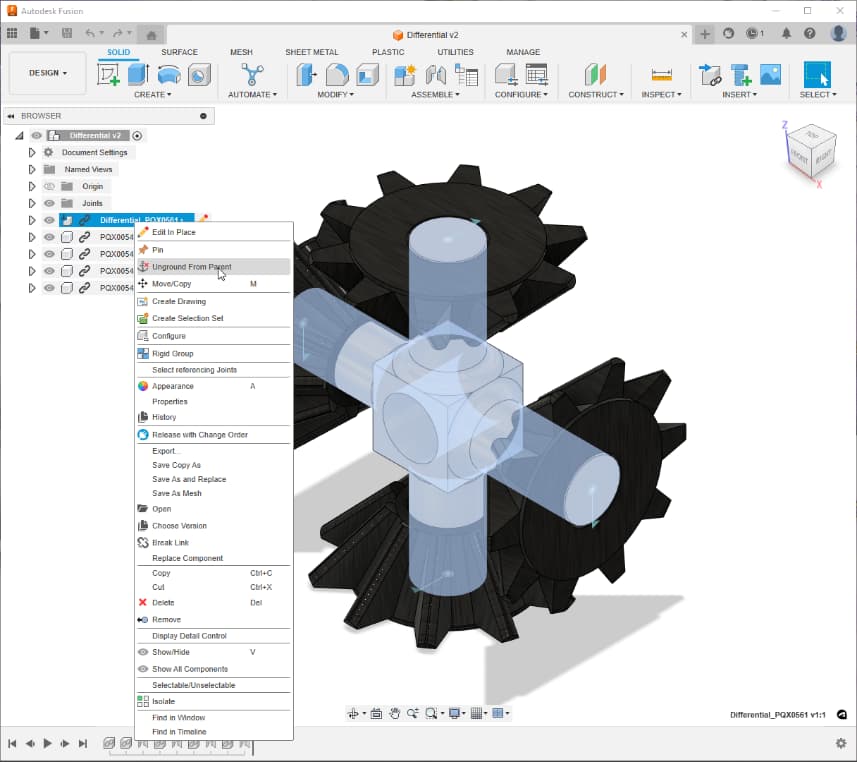

One of the key enhancements we launched this year was the “Ground to Parent” feature. Now, when you create or insert an external or internal component into an assembly, the first component is “grounded to parent” by default. This feature allows you to easily select other components to be grounded to the parent through the right-click menu in the browser, and unground them in the same way. By helping eliminate the need to create a joint, Ground to Parent helps by reducing timeline clutter and saving you clicks.

Learn more about Ground to Parent.

Another exciting addition is the “Edit Initial Position” (EDIP) feature. This allows you to modify the initial position of a component directly from the context menu, without adding new features to the timeline. This streamlines the design process and is applicable in both Parametric and Direct Modeling environments, as well as Edit in Place (EIP) mode and the PCB package generator workspace.

Learn more about Edit Initial Position.

We’ve also introduced a new “Insert Component” command. Previously, inserting a design into another design required navigating the Data Panel, which was not always intuitive. Now, a formal command on the toolbar’s “Insert” panel simplifies this process. This command opens a file browsing dialog, allowing you to select and insert designs as xref components into the current design. These improvements are part of our ongoing efforts to enhance Fusion and make your design work more efficient and intuitive.

Offset Enhancements

We’ve also made some exciting enhancements to our Offset capabilities, designed to give you more flexibility and precision in your projects. With the new “Two Side Offset” feature, you can now create offset geometries on either side of your selected geometry at the same distance, giving you the option to link or unlink the two offset dimensions. This means you can set a primary offset dimension, and the secondary offset dimension will automatically adjust as an expression of the primary, giving you better parametric control.

As part of upgrading our Offset experience, we released the “Offset of Offset” feature, which allows you to create an offset from an already offset geometry. This eliminates the need to create multiple offsets from a single parent, streamlining your workflow. This feature has been highly requested and now applies offset dimensions and constraints with respect to the selected offset child. To round out the enhancement we followed up with “Match Offset Topology”, a feature that gives you control over topology changes during offset creation, so any changes in geometry or parameters that would alter the topology of the offset child are visually indicated and not allowed, preserving the integrity of your design.

Continued Investments in Configurations

We spent a good portion of this year filling in critical usability gaps in Fusion Configurations, such as the ability to autocomplete parameters in the table, duplicate configurations, configure aspects of mesh bodies, leverage our API, and more.

In the latter part of the year, we delivered new capabilities to enhance your Fusion Configurations workflows. We introduced a Configure tab to some of the most-used modeling commands in Fusion, allowing you to configure aspects as you model without interrupting your design flow. We also simplified the process of configuring the placement of components in an assembly by introducing configurable Snap and Flip aspects for Joint features.

These highlights are only a small portion of what we’ve launched this year, from updated UI to a more user-centered table experience there is so much to explore.

Learn more about Configurations.

Strengthening the Fastener Library

Back in 2023, we added an integrated fasteners library to Fusion, and since then, we’ve been committed to enhancing your experience by continuously increasing the variety of fasteners and making the library more user-friendly with every update.

Last year we added many enhancements sprinkled throughout the Fastener Library, let’s break down a few of our favorites:

- Fastener Favorites, allows you to create a subset of frequently used parts for quick access without the need for searching or browsing.

- The ‘Replace Fastener’ command enables you to substitute an existing standard part with a different type, such as replacing a hex head bolt with a socket head bolt.

- The Fastener Search function helps you quickly find the fasteners you need.

- The Flip option lets you reverse the joint direction when placing fasteners on a sketch point, providing greater flexibility in your designs.

- An expanded model database and new Rivets category give you more options to find precisely what you are looking for when you need it.

These enhancements are designed to make your fastener placement more efficient and intuitive, allowing you to focus on your design work.

Learn how to Insert a Fastener.

Drawings

We started off the year strong with the introduction of Automated Drawings, which enable you to save significant time by automating the tedious steps of creating a drawing. This feature automatically scales and nests views on a sheet, places parts lists and balloons, rotates components for optimal documentation, creates break views for long components, applies center lines and center marks, places sheet metal flat patterns and bend tables, retrieves hole and thread notes, and generates dimensioning strategies.

Additional Enhancements

Since then, we’ve introduced several other enhancements to improve your drawing experience, here are some of our favorites from recent updates:

- Custom Sheet Sizes now give you full control over sheet dimensions, including automatic Zone creation and the ability to set Portrait or Landscape orientations.

- Breakout Section Views let you create partial section views to highlight specific internal details of your model.

- Hatch Pattern Enhancements include “Solid Fill” hatches and 15 new hatch patterns, along with a revamped hatch command interface.

- Match Dimension feature enables you to quickly copy tolerances from one dimension to another.

- Added support for Multiple Configurations in a Drawing allows you to insert different configurations of the same design on one or multiple sheets, making it easier to track progress and compare designs.

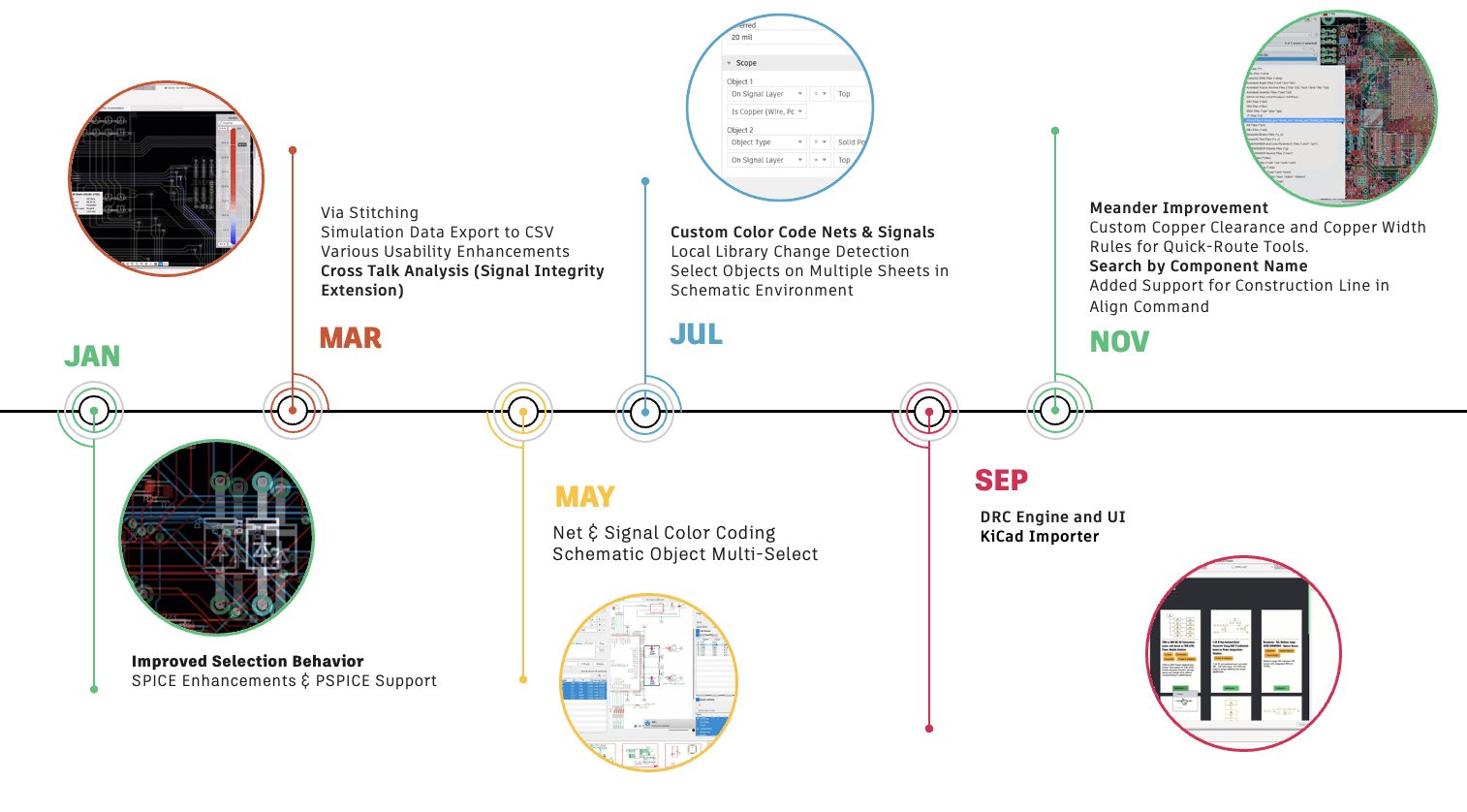

Electronics

One of the key value propositions of fusion is bringing together design through manufacturing workflows, and electronics is a key component of that. This year was a big year for the electronics team. We’ve delivered so many different experiences, capabilities, new partnership opportunities, as well as core capabilities, let’s take a look.

Selection, Probing, and Color Code

The enhanced asset selection functionality redefines navigation by enabling assets to be highlighted upon hover and selectable without reliance on their origin. With the addition of marquee selection, users gain precise control: selections from left to right capture only fully enclosed assets, while selections from right to left include partially covered assets, supporting a more efficient and intuitive design experience.

Selected assets in the schematic are now automatically highlighted on the board and vice versa, providing a more efficient experience for tracking and troubleshooting your design. This year, we also introduced a feature that enables color-coding of net classes and signals, simplifying critical connections’ tracking, routing, and flagging. Colors persist in override mode across layers, improving complex boards’ organization and management of complex boards.

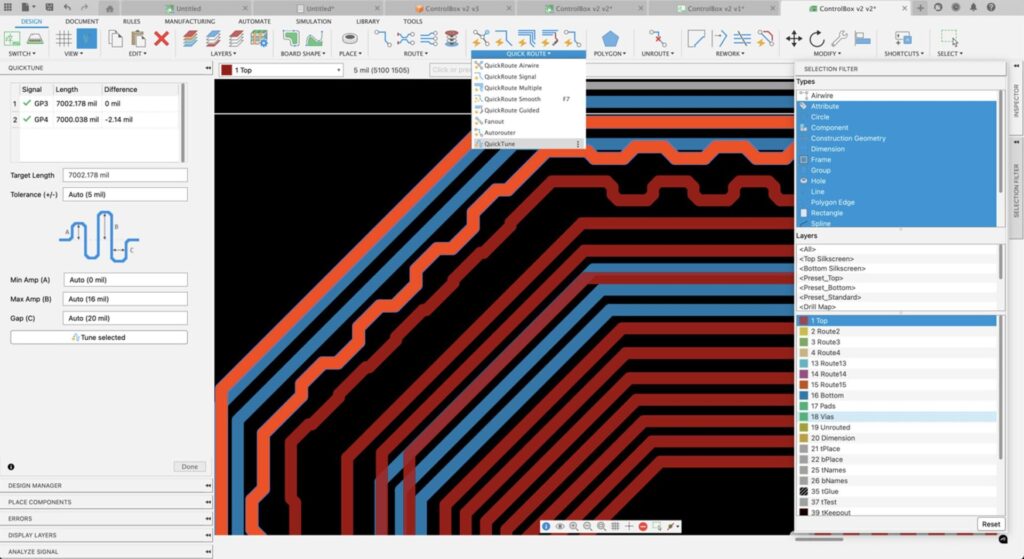

Design Constraints Reimagined, Quicktune, and Via Stitching

The design constraints feature has been reimagined with the introduction of Design Preferences and Design Rules. Design Preferences apply globally across the design, while Design Rules offer advanced, scoped constraints for greater control. This new approach empowers users to tackle complex designs, helping accelerate innovation.

Meander and the new QuickTune offer an improved interface for precise control over the gap and amplitude of your meanders. Additionally, our developers have introduced automation capabilities, streamlining adjustments for Differential Pairs or selected traces.

Building on Autodesk Fusion’s innovative polygon plane techniques, the new Via stitching feature allows you to define areas or fill the entire board with Vias. This will enhance PCB electrical and thermal performance and signal integrity while adhering to Manufacturing Design Rules.

Align with Construction Lines

We’ve also introduced a feature that enables the alignment of PCB assets with construction lines from the Fusion Design or 3D workspace, bridging the gap between mechanical and electronic engineering. This integrated workflow helps reduce file conversion hurdles, allowing mechanical engineers to draw reference lines directly on PCB layouts for precise component placement. By leveraging the Align command, electronics engineers can position assets accurately, enhance alignment, and reduce design time.

Learn more about our Cadence partnership.

Partnering for a Brighter Tomorrow

The Signal Integrity Extension now provides detailed insights into differential pairs—those critical traces often found in USB connectors. You can increase optimal performance for your high-speed designs by analyzing coupling coefficients and mitigating crosstalk.

Manufacturing

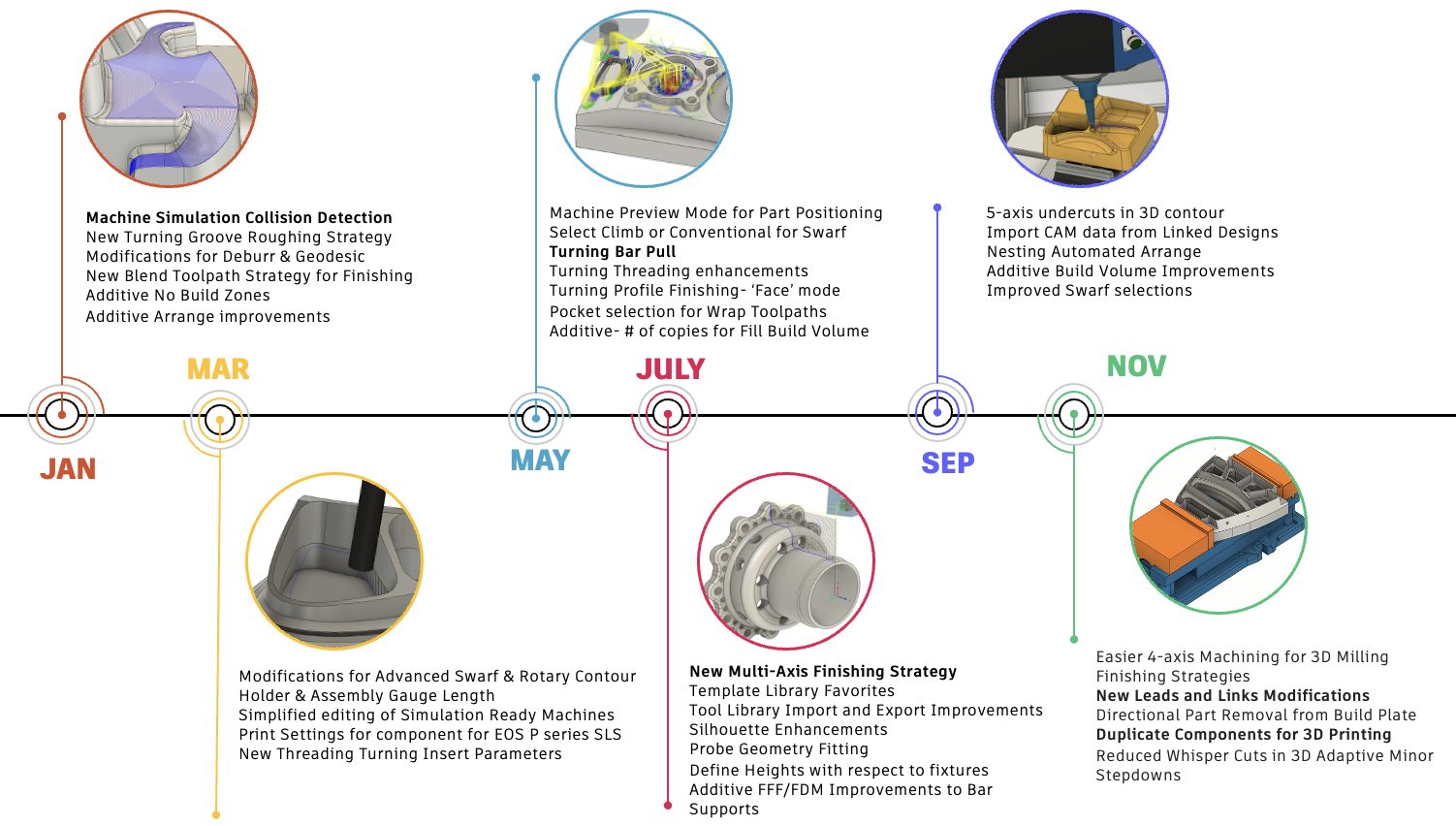

Our focus remains on developing the best manufacturing tools tailored specifically for you. This year, our investments have focused on addressing the real-world challenges facing you and your shops. Let’s dive into some of our favorite highlights from this year.

Milling

This year, we took significant strides in enhancing machining safety and efficiency. One of our favorite enhancements was the addition of Machine Simulation Collision Detection. This game-changing feature identifies potential collisions and axis over-travel on machine tools before program execution, minimizing downtime and ensuring operational safety.

To make your manufacturing experience more efficient than ever, we added a New Blend toolpath strategy for finishing that makes machining a surface with passes that blend smoothly between two designated drive curves a breeze. We also added the Avoid Machine feature, which provides granular control over toolpath clearances, enabling users to specify radial and axial clearances for various surface groups, enhancing precision and flexibility in machining operations.

Throughout the year the Manufacturing Extension also saw major enhancements, providing you with new opportunities to streamline how you work.

- The Multi-Axis Finishing Strategy offers versatile cutting modes and automatic tilting capabilities for complex pocket-shaped geometries.

- Advanced Swarf toolpath strategy allows straight-sided walls to be machined with the side of the tool. This strategy provides control for categorizing surfaces as swarf surfaces, floor surfaces, or surfaces to be avoided, giving great control over the toolpath.

- New Leads and Links Modifications, allowing adjustments without full recalculations, significantly reducing programming time

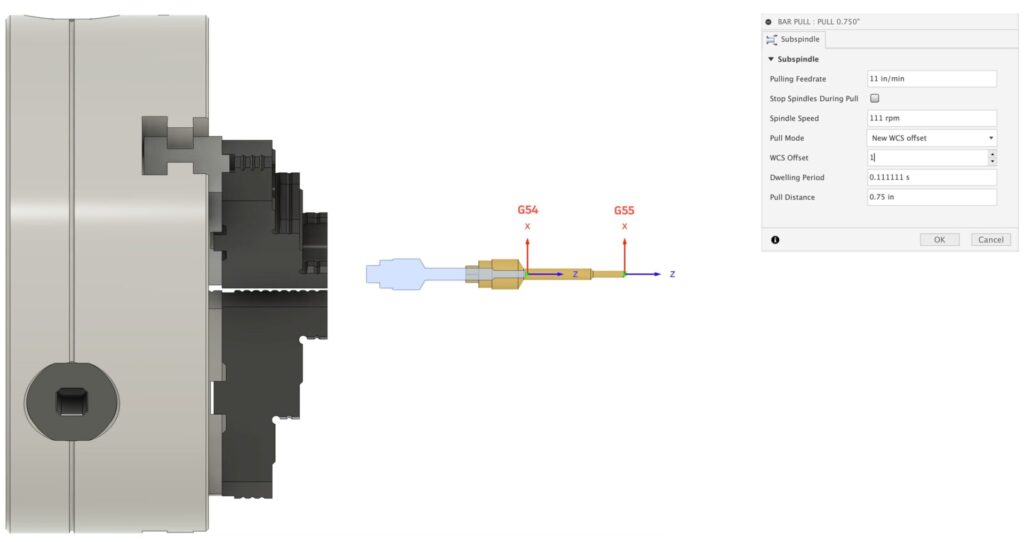

Advancements in Turning

We introduced significant enhancements to turning threading capabilities over the course of this year, including precise control over threading tools, thread tip conditions, and the support for various thread insert types. Some of the key improvements are:

- First Pass Depth Control added the ability in turning threading operations for the user to define the depth of cut for the first pass.

- “Face” Mode introduced “face” mode to turning profile finishing operations to machine turning features on the face of a part.

- Increased Z Confinement Options added the ability in turning threading operations to select the Z confinement of the thread in more flexible ways and to be consistent with other turning strategies.

Learn more about some of our recent investments in Turning.

Improved Tool Libraries

We know Tool libraries play a vital part in how you work, so to help make this experience better than ever we introduced new Vendor Tool Libraries. This feature integrates vendor tool libraries directly into the tool library interface. Previously, you needed to download and upload these libraries manually, but now they are accessible directly in the library tree, streaming from an online repository. This integration ensures no performance lag and allows tools to be used directly from the vendor library or moved to a cloud, local, or document library for editing.

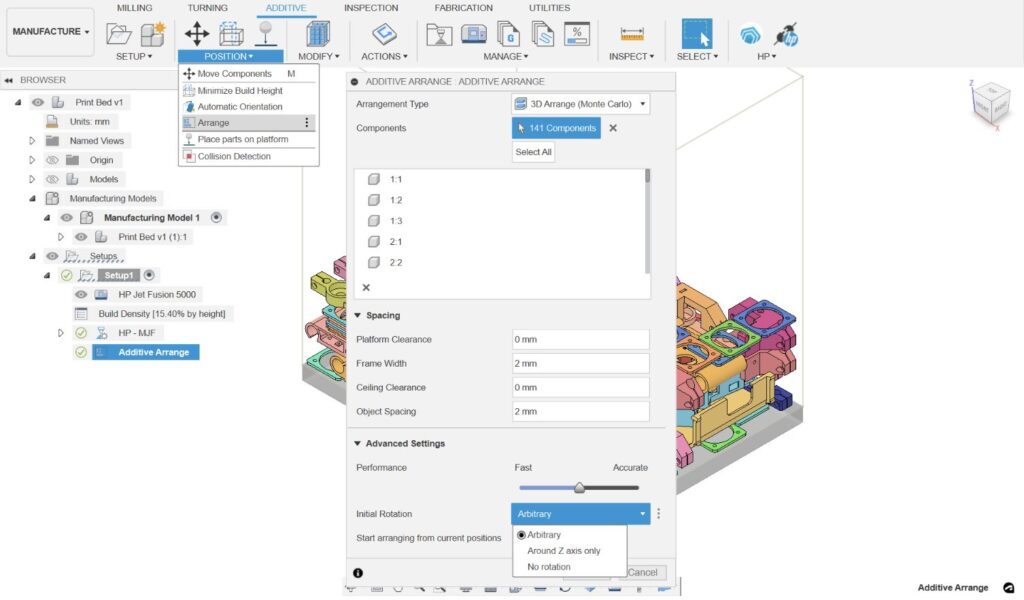

Additive Manufacturing

Additive manufacturing is quickly revolutionizing traditional manufacturing by enabling the creation of complex and customized products with reduced material waste, shorter production times, and greater design flexibility. This year, our teams have worked tirelessly to introduce significant enhancements to our Additive Manufacturing capabilities, allowing you to stay at the forefront of technology.

- Duplicate Components feature allows you to easily replicate components within the 3D printer’s build area directly in the Additive Setup, offering multiple placement options including manual or automatic rearrangement, bounding box pattern creation, and the True Shape algorithm for optimal spacing.

- Additive Arrange tool saw a major upgrade with the introduction of the Monte Carlo packer, which optimizes 3D component arrangement by simulating a shaking process to reduce build height and prevent interlocking.

- No Build Zones for 3D printers allow you to edit machines in their local or cloud libraries and designate a no-build zone using a 3mf file.

- New Additive Machines and Print Settings provide users with a broader range of options, enhancing their ability to create complex and high-quality 3D-printed products.

These advancements collectively mark a significant leap forward in our commitment to providing cutting-edge tools for the additive manufacturing community.

Thank You for a Fantastic Year

To our incredible community of users, we extend our heartfelt gratitude. Your creativity, feedback, and unwavering support have been the driving force behind our continuous improvement and innovation. Thank you for being a part of the Fusion journey. We are excited about the future and look forward to achieving even greater heights together in the coming year.

Shape the Future of Fusion

Do you want to engage more with the Autodesk community, use exclusive previews, and test out the latest build before it’s released to the public? Check out the Fusion Insider program!

The Autodesk Fusion Insider Program enables you to access the next version of Fusion and all the new features, improvements, and fixes, 3-4 weeks before the general public. As a member, you’ll gain inside knowledge of when we are deploying an update, as well as a first look into what’s new and what’s coming next. You will also have the opportunity to join exclusive events, try pre-release functionality, and give feedback straight to the product teams.