The manufacturing industry is in a crisis. Amidst a storm of disruption, one challenge towers above the rest: the crippling skills gap. Finding qualified machinists ready to hit the ground running is like searching for a needle in a haystack. And upskilling the existing workforce? A daunting uphill battle.

The numbers paint a bleak picture. Nearly two million manufacturing jobs could be left unfilled by 2033, according to Deloitte and The Manufacturing Institute. Meanwhile, 43% of business leaders see talent shortages as a major roadblock, as revealed in Autodesk’s 2024 State of Design & Make report. It’s time for radical change. The industry’s future hinges on finding innovative solutions to this urgent problem.

Delivering a one-of-a-kind curriculum

Autodesk and Haas Automation have been engineering a powerful partnership for years, seamlessly merging Autodesk Fusion CAD/CAM with the precision of Haas CNC machines. Our shared vision extends beyond product integration. We’re committed to closing the skills gap that’s plaguing the manufacturing industry.

More than 100 million educators and students globally are using our products for free to bridge the talent gap of critical skills that design and make industries need in the next generation of talent. Haas has equipped thousands of schools with state-of-the-art machines and established training centers to foster a new generation of skilled workers.

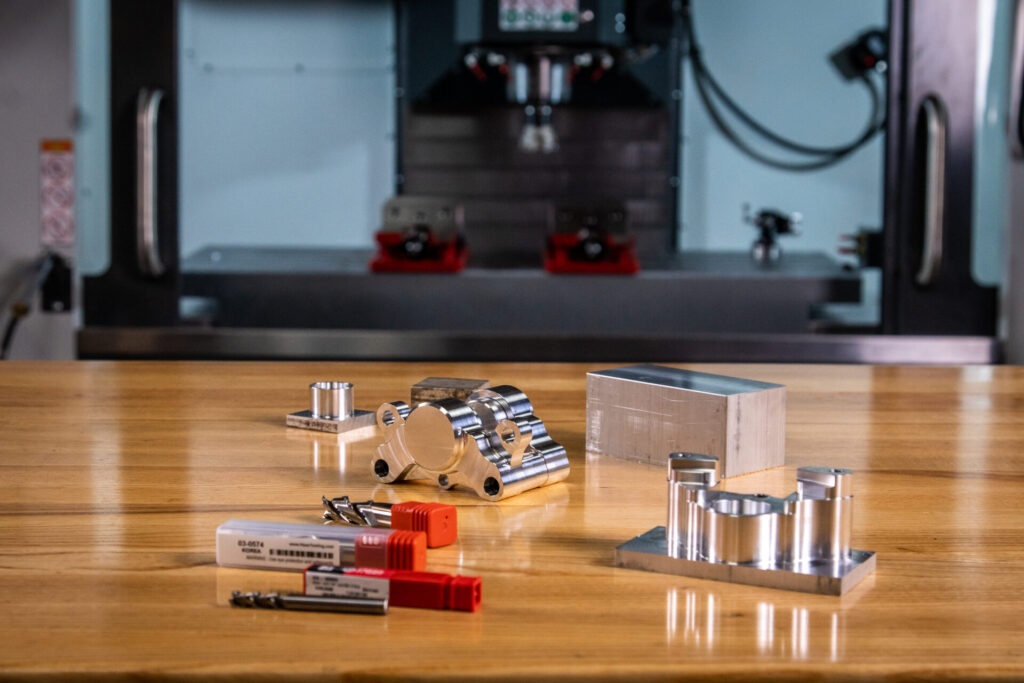

Now, we’re taking it to the next level. Our new Haas and Autodesk Fusion – CAD, CAM, and CNC for 2.5-axis milling curriculum is a groundbreaking, end-to-end learning experience. Unlike traditional programs that silo CAD, CAM, and CNC, ours seamlessly blends them together in an industry-validated way. Students not only master the software but also gain hands-on experience operating Haas machines. With pathways to earn industry-recognized certifications from both Autodesk and Haas, graduates will hit the ground running, ready to excel in today’s competitive job market. This curriculum is more than just training; it’s the foundation for a thriving career in manufacturing.

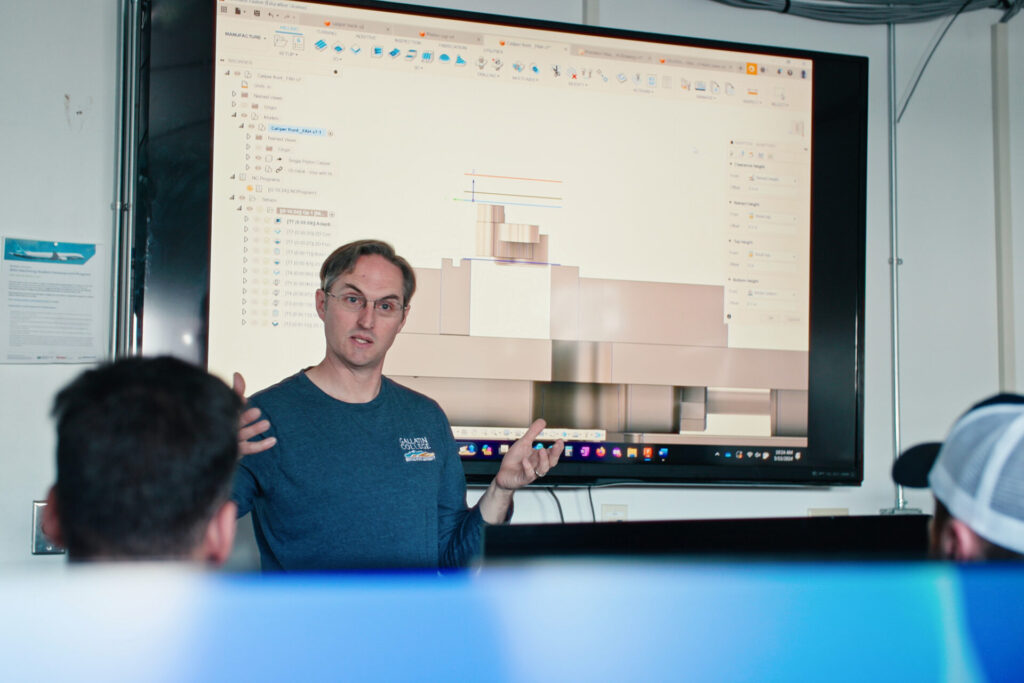

Imagine a classroom where students aren’t just learning ‘clicks and picks’, but crafting tangible results, designing and making a real-world motorcycle brake caliper. From concept to creation, educators and students can embark on a journey, blending hardware and software in a way that mirrors real-world industry standards. The payoff? Students emerge with not just a diploma, but a physical testament to their skills—a part they’ve designed and built with their own hands.

It’s a walking, talking portfolio that says, “I understand how to design and make something, and I’m proud to share my learnings through this journey.” Companies will value a candidate who can openly discuss both their failures and successes. So what’s the best news? This transformative curriculum is open to everyone, absolutely free.

Learning a holistic, design for manufacturing process

During my time as an adjunct faculty member at a vocational college, I vividly recall the frustration of teaching CAD in isolation. Design and manufacturing felt like two separate worlds, never coming together. It was a missed chance to create a more holistic learning experience. Now the Haas and Autodesk Fusion curriculum brings these two worlds together. From my years in the classroom, I’m confident that educators will be thrilled by these in-depth, ready-to-go courses.

By immersing students in real-world projects, we can evolve how they learn. From deciphering blueprints and CAM setups to mastering CAD modeling, crafting toolpaths, and machining parts, future machinists and engineers gain a holistic view of the design process. Instead of getting lost in technicalities, they’ll grasp the big picture, the why behind the how. This hands-on, project-based approach is essential to cultivating the design for manufacturing (DFM) mindset, a cornerstone of Industry 4.0 success.

“With students being able to finish [the curriculum] with finished parts, they get to have something in hand—and they can say, ‘Hey, I made this. I actually can do this job,’” says Aubrin Heinrichs, CNC machining program director at Gallatin College, Montana State University.

Learn more about the new Haas and Autodesk Fusion – CAD, CAM, and CNC for 2.5-axis milling curriculum and how to get started.