This post is also available in: Deutsch (German)

Check out this comprehensive guide to 3D printing and 3D modeling basics. Learn about important terminology you should know, 3D printers, and extremely fast cloud CAD software.

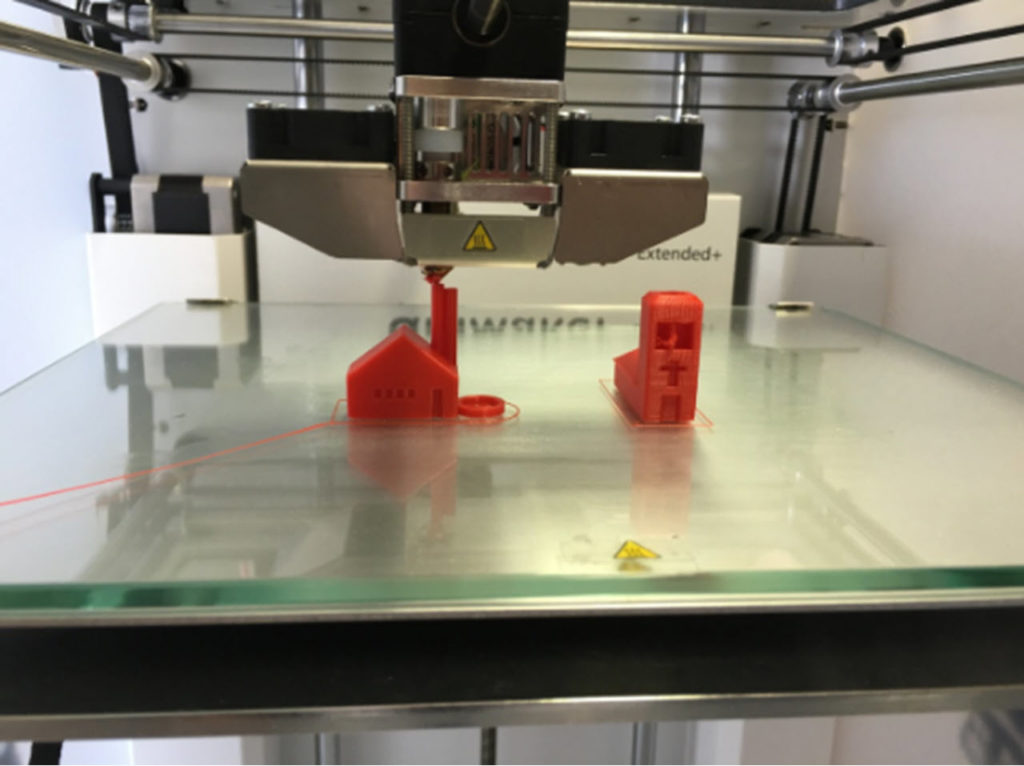

Whether you are an up-and-coming college student or a veteran engineer, learning or revisiting the fundamentals of three-dimensional (3D) printing is extremely valuable. 3D printing isn’t just a futuristic dream anymore. Industrial designers often use 3D printing to create prototype scale models to test their design’s form, function, and fit. 3D printers are as versatile as ever with various features, materials, and applicable 3D software packages like Autodesk Fusion 360.

Designers typically have a design (or dream) in mind to begin. 3D printing helps bring that dream to fruition. This article discusses the fundamentals of 3D printing to help you go from dream to done in no time.

What is 3D Printing?

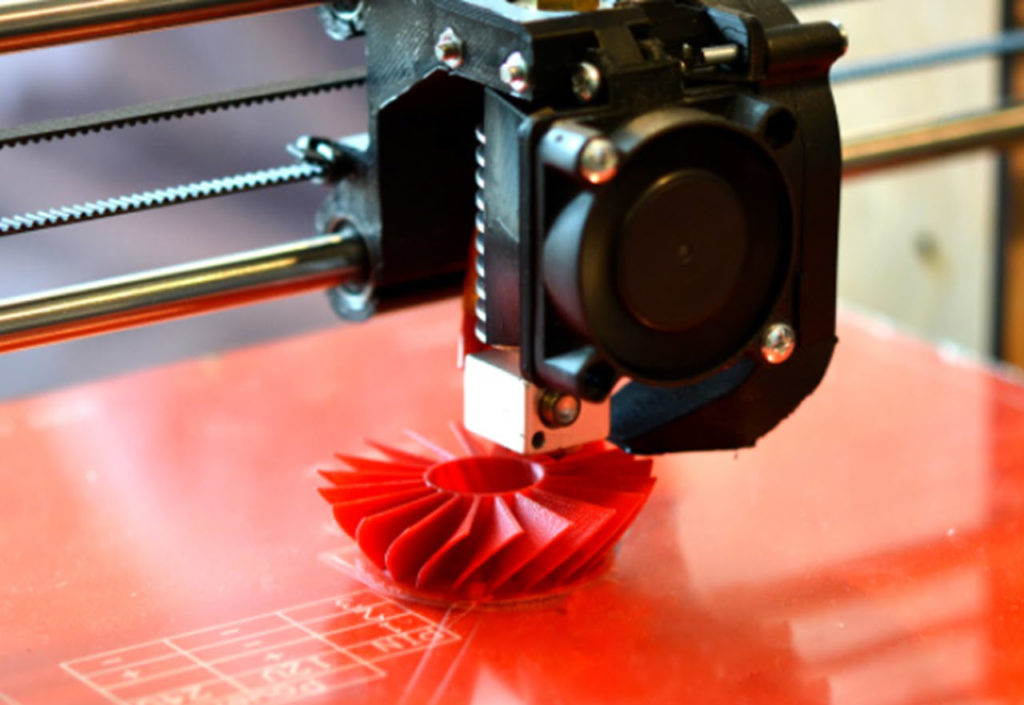

3D printing, also known as additive manufacturing, is printing a 3D object from a digital design. Unlike traditional subtractive processes, 3D printing is an additive process. It takes a solid object and then carves or reduces it into the ideal design. Essentially, the 3D printer uses a digital blueprint to mold a physical product. For example, some 3D printers use a heated material, like plastic, to create a layer on top of other layers, which eventually stacks up in three-dimensional space to create an object.

3D printing was introduced in the late 1980s but didn’t draw serious attention until the 1990s. As with any new technology, many people saw 3D printing as only possible in science fiction. However, 3D printing gained traction and is now being integrated into several industries.

3D printing Terms and Definitions

It’s helpful to understand the vernacular associated with the 3D printing process before diving into the wide world of additive manufacturing. Not every term can be listed or understood in one blog post, but the list below should help you kickstart your project.

- Additive manufacturing: Another term for 3D printing. The process of adding materials to create a physical object.

- Bed leveling: The process of leveling a 3D printer’s build plate.

- Bowden extruder: An extruder type for FDM printers that has a separated hot end and extruder motor.

- Computer-aided design (CAD): The process of designing parts or other objects in a digital environment before 3D printing.

- Computer-aided manufacturing (CAM): The process of using software and computer-controlled machinery to automate a manufacturing process.

- Curing: The process of using UV light to solidify liquid resin.

- Digital light processing (DLP): A printer that projects light over an entire layer to cure the resin all at once.

- Direct drive: This device is different from the Bowden extruder because the extruder motor sits on top of the hot end.

- Elephant’s foot: A common problem where the first layer is distributed wider than needed. This problem can be solved by adjusting the 3D printer settings.

- Extruder: A motor with gears that feeds filament to the printer’s hot end.

- Filament: Material used in 3D printing.

- Fused deposition modeling (FDM): A 3D printing method where material layers are fused together in a specific pattern.

- G-Code: The language used to create commands for 3D printers.

- Hot end: Consists of a heating cartridge and a thermistor to heat the filament.

- Infill: This is the interior of the printed object. Infill patterns vary and help provide adequate internal structure to the printed object.

- International Organization for Standardization (ISO): A worldwide standard of quality management for any organization.

- Liquid crystal display (LCD): A printer that uses an LCD screen to mask a projector’s light or uses its own light to cure an entire layer at once.

- Selective laser sintering (SLS): An industrial 3D printing process that uses a laser to fuse a thermoplastic powder to build prototype parts.

- Stereolithography (SLA):A printer that uses a laser to cure liquid resin with pinpoint precision.

- Striping: Striping is a common problem with FDM printers where individual layers become visible in the end product.

- Thermoplastic: A type of plastic made of polymer resins that soften when heated and hardens when cooled.

- Vat Polymerization: Resin-based 3D printing where liquid photopolymer resin is stored in a vat (unlike other printers that force thermoplastics through a nozzle). Subcategories of vat polymerization include stereolithography (SLA), digital light processing (DLP), and liquid crystal display (LCD).

3D Printers for Beginners

A 3D printer operates on the X, Y, and Z-axes:

- The X-axis is the left-to-right movement.

- The Y-axis is the front-to-back movement.

- The Z-axis is the upward and downward movement.

The extruder is installed on the X-axis and feeds filament onto the build plate (print bed). The build plate is often heated and can adjust for leveling and temperature.

Types of 3D printers

There are several types of beginner-friendly printers on the market. The most common are FDM, SLA, and SLS printers. FDM printers are generally the cheapest option for beginners or homebrewing engineers. They are easy to maintain and filament to feed the machine is relatively affordable compared to the other two options. The downsides of FDM printers include clogged nozzles, difficult clean-ups, and striping.

SLA printers utilize liquid resin hardened by UV light to create a final product. These printers are great for intricate details (down to 25 microns) but cost a few thousand more than FDM printers. Disadvantages of SLA printers include clogged nozzles, limitations on available materials, and final products that can be potentially brittle.

Lastly, there are SLS printers. The main difference is that SLS printers use powder instead of liquid resin. These printers are the most expensive and generally cost over $50,000. However, they provide detail down to 16 microns and do not require infill patterns for stability. SLS printers can use materials other than resin, like aluminum, silver, or steel. Naturally, the biggest disadvantage is the price tag.

Choosing the right printer can be a difficult task, but the choice lies within the application. What will you use your printer for? Determining the printer’s application, cost, and size will all factor in your decision. Companies like Formlabs can provide specifications and factor individual costs for printers and associated equipment.

But a 3D printer is useless without proper software.

The Ideal Software for Beginners

Just like 3D printers, CAD software comes in various shapes and sizes. For example, Autodesk Fusion 360 provides an integrated, easy-to-use cloud CAD environment for beginners and experts alike. If you’re not ready to purchase a 3D printer or CAD software, consider utilizing Xometry’s industry-leading 3D printing services. Xometry provides an online marketplace for engineers or regular people to create or have something created.

Getting Started with Fusion 360

Consider Autodesk Fusion 360 when beginning your 3D printed project and join the more than 1.2 million innovators who have already switched to Autodesk’s software platform. Fusion 360 provides fast and efficient cloud CAD and a library of instructional content, tutorials, and additional information.

Go from dream to done with Fusion 360 today!