Discover the benefits of 4-axis machining with Fusion 360, including enhanced precision, reduced tool deflection, fewer setups, and more.

In the world of advanced manufacturing, staying ahead of the competition is essential. To achieve this, businesses need to adopt cutting-edge technologies and techniques that improve productivity, precision, and profitability.

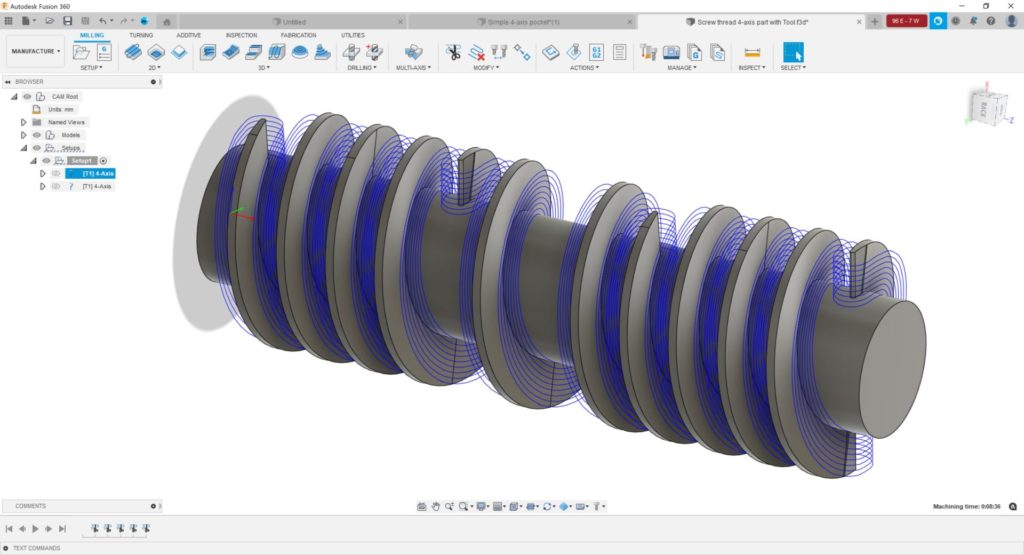

One such technology is 4-axis machining, which offers a range of benefits for machining complex parts. When combined with powerful software like Autodesk Fusion 360, the advantages become even more pronounced. In this article, we’ll explore the benefits of 4-axis machining using Fusion 360 and how it can revolutionize your manufacturing processes.

Benefits of 4-axis machining

- Shorter tooling: Levelling up from 3-axis to 4-axis machining can have a huge impact on machining flexibility. The addition of an extra rotary axis can allow features and geometry to be machined using much shorter cutting tool assemblies. These shorter tools are typically more rigid. This allows programmers and machinists to run at more aggressive feeds and speeds, reducing overall machining cycle times.

- Less tool deflection: Another benefit of using shorter cutting tools is a reduction in the likelihood of cutter deflection occurring during machining. This can help increase dimensional accuracy and improve surface finish, reducing the need for costly manual polishing.

- Fewer setups and reduced human error: By utilizing 4-axis machining, there is a significant reduction in the number of setups required to machine components. This greatly reduces overall setup time and increases manufacturing throughput. It also minimizes the potential for human error, improving part quality.

- Enhanced part quality and reduced costs: With fewer setups, there is less chance for mismatch and scope for expensive repairs. The improved part quality eliminates the need for manual polishing or hand finishing, reducing costs and saving time.

- Increased profitability: Leveling up to 4-axis machining enhances the profitability of your business in more than one way. It allows you to take on more complex and valuable projects, giving you a competitive advantage in the market.

4-axis machining capabilities in Fusion 360

- 3+1 machining: This is the simplest type of 4-axis machining – and the one that offers the biggest bang for the buck. Here, we use the 4th axis of the machine to rotate the component into position then use 2D and 3-axis strategies to machine the various features on the part. Once the features are machined, we rotate the 4th axis into the next position and repeat the process.

- Efficient machining of free-form shapes: Simultaneous 4-axis machining sees all four axes of the machine moving at the same time. This enables the efficient machining of free-form and cylindrical-like shapes that are either impossible or impractical to produce with 3-axis or 3+1 machining alone. This can open up possibilities for businesses allowing them to produce more complex, higher-value parts.

- Automated deburring: Automatic deburring of sharp edges (3-, 4-, and 5-axis) improves throughput by removing the manual process. This saves time and money, while also ensuring consistency and avoiding potential health and safety issues.

- Collision checking for safety and efficiency: Full machine simulation and collision avoidance are vital in 4-axis machining. The software detects potential collisions, ensuring safe and efficient machining by automatically adjusting toolpaths and avoiding collisions with the shaft and holder.

4-axis machining offers a wide range of benefits, including enhanced machining capabilities, improved tooling setup, reduced tool deflection, fewer setups, enhanced part quality, reduced costs, increased profitability, and competitive advantage.

By leveraging the 4-axis machining power of the Autodesk Fusion 360 Machining Extension, businesses can achieve greater precision, efficiency, and profitability in their manufacturing processes. From intricate geometries to optimized toolpaths, Fusion 360 provides the tools and capabilities necessary for advanced manufacturing.

Ready to take your machining processes and your business to new heights? Try the Fusion 360 Machining Extension, free for 14 days.