For a very long time, manufacturing has been a world of high quantities and proprietary techniques. It didn’t matter how the work got done, it just needed to get done (en mass and on time).

Now, in a world of ever-increasing production quotas, we are constantly looking for ways to improve production efficiency and finding ways to make things move faster. It’s been said that by 2020, 25% of the world’s economy will be digital. This means that manufacturing needs to follow suite.

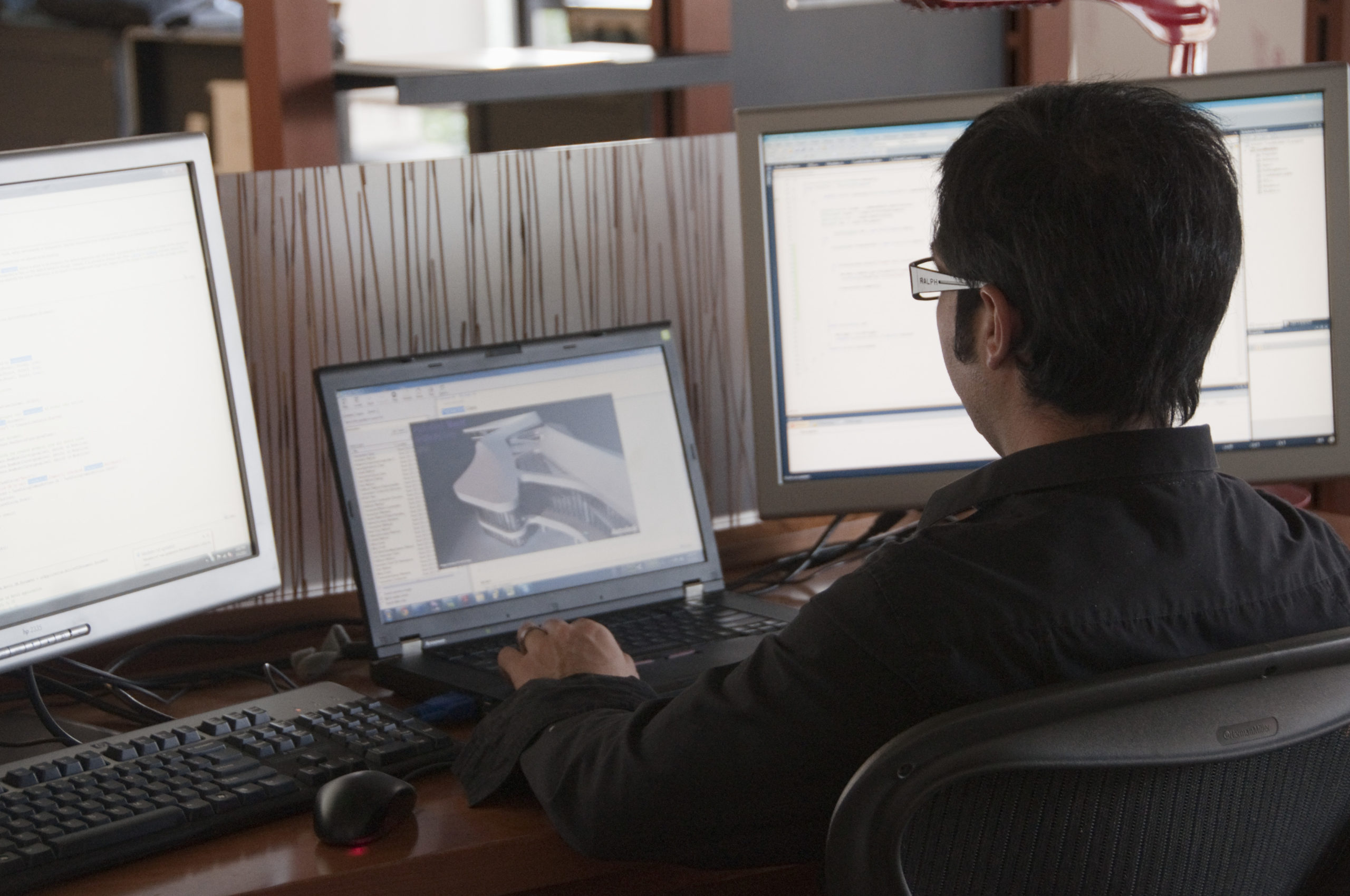

The industrial world has started to enter the digital age, with the incorporation of CAD, CAM, and various automation practices, but there is so much more.

Going lean is a technique that is designed to help manufacturing businesses increase their efficiency by reducing waste. But, the first step to reducing waste is finding it.

Utilizing a buzzword, internet-of-things or IoT, is essential to finding and reducing waste in the manufacturing process. This is all about digitizing your manufacturing processes.

Data has always been important in the world of design, but it is unmistakably more important in manufacturing. More sensors, more reporting, digital quality control, and aggregating all of that data into a digestible format.

Because so much of the manufacturing world is based on high volume practices, saving a few thousandths on a part, cutting seconds off of a cycle or curing time, or making a tool last just a bit longer can save thousands if not hundreds of thousands of dollars.

While adding big data to your manufacturing processes might seem cumbersome and/or expensive, especially if you have a large operation, it is vital. By adding just a couple data points (as a starter), you have the ability to drastically save on adjusting manufacturing practices. If you operate a smaller manufacturing operation, adding big data and the internet of things to your infrastructure can be much easier.

Whether your operation is large or small, the key is finding potential pinch points and adding some sort of sensor or monitor. Allow that monitor to gather data, and then start adjusting from there. You may be surprised at how quickly adding data will help make your business better.