From robotic automated manufacturing to the future of personal transportation, entertainment innovation to consumer tech, BRCHN Design House has a proven track record of concept to market product development across a plethora of industries. Utilizing cutting edge design tools, visualization renderers, and prototyping technology, along with a focus on sustainability, manufacturability, efficiency, and quality design, they blur the lines between art and science to create beautiful, functional products.

So if you’re reading this, you probably have some sort of interest in designing something in the physical space. This is awesome for a number of reasons (in my opinion).

First, most (like 8/10) startups I come across are exclusively in the digital space. So it’s cool to be doing something a bit different! There can be something special about human interaction with tangible products that will be forever absent in the digital world.

Second, the manufacturing and prototyping industries are extremely exciting right now. With astounding machinery technology development in recent times (metal 3D printing, additive & subtractive hybrids, high speed machining, etc.), I think we are on the cusp of a mini technological industrial revolution. As technology levels the playing field, the opportunity to manufacture close to home is growing and viable.

Finally, design & manufacturing are becoming more sustainable and more fun! Software (Fusion 360 leading the way) & hardware are becoming more in tune with natural human brain processing. The days of not being able to make organic shapes due to CAD or machining limitations are quickly diminishing. Having the ability to take what’s in our brain and make it a ‘thing’ in real life with as little compromise & interference as possible allows us to design more freely & creatively.

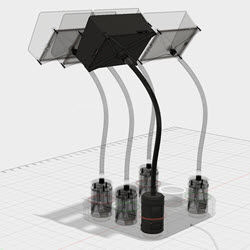

As I alluded, the biggest advantage of using Fusion 360 for us is the ability to work in both parametric and surfacing environments simultaneously. It goes hand in hand with our business model as a design & engineering firm, and it goes hand in hand with the emerging era of manufacturing. I might dive deeper into this on a future post, but for now, here’s an example.

This sustainable commuter concept vehicle has a number of design and engineering considerations: packaging, suspension geometry, aerodynamics, material properties, ergonomics, adaptability, aesthetics, and safety to name a few. Just as we’re not going to model aesthetics using math and science, we’re not going to engineer safety features based on what looks good. Jumping seamlessly between environments in Fusion 360 ensures we have the right feature-set for every design, engineering, and prototyping decision.

At BRCHN Design House, we keep a very close eye on the engineering software market as the tools in our wheelhouse directly influence our process efficiency. The software and hardware we use might not always be in the top two or three percent of latest and greatest tech for a specific niche, but it’s not far off. This is largely what gives us the opportunity to compete with much larger firms. So do we use the cloud-based collaboration, FEA simulation, and CAM? Absolutely! It’s icing on the cake to have that functionality at an industry leading level in a single piece of software. For the last two years, Fusion 360 has been the tool with the largest comparative advantage over industry standards for us. I suspect that to remain true until it becomes the industry standard.

Browse our website for more information, check our Facebook page for day-to-day posts, and don’t hesitate to reach out if there’s anything we can do for you!