Category: Advanced Manufacturing

-

Advanced Tooling: The Key to Faster, Better, and Cost-Effective Machining

Boost manufacturing speed, quality, and savings with advanced tooling. Discover how Fusion for Manufacturing unlocks efficiency and superior results for your team. The pressure to deliver high-quality parts quickly and cost-effectively has never been greater. Manufacturers are constantly seeking new ways to boost productivity, improve surface finishes, and reduce operational costs. One of the most…

Advanced Manufacturing

-

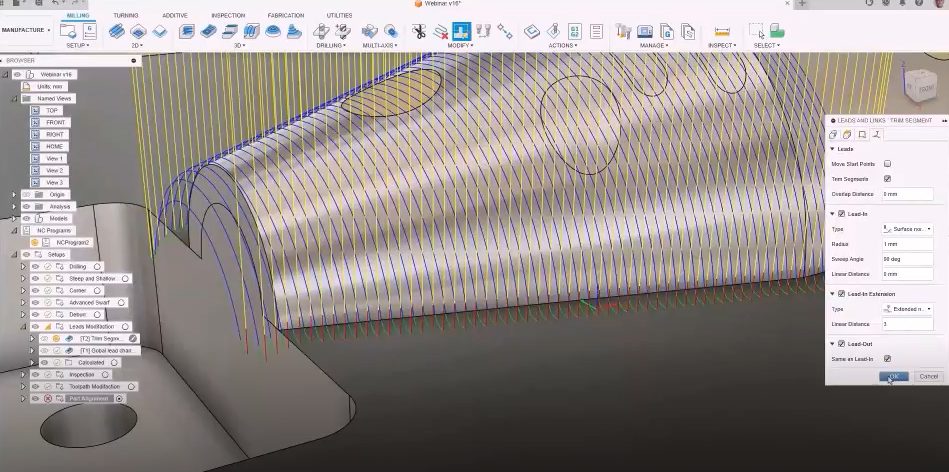

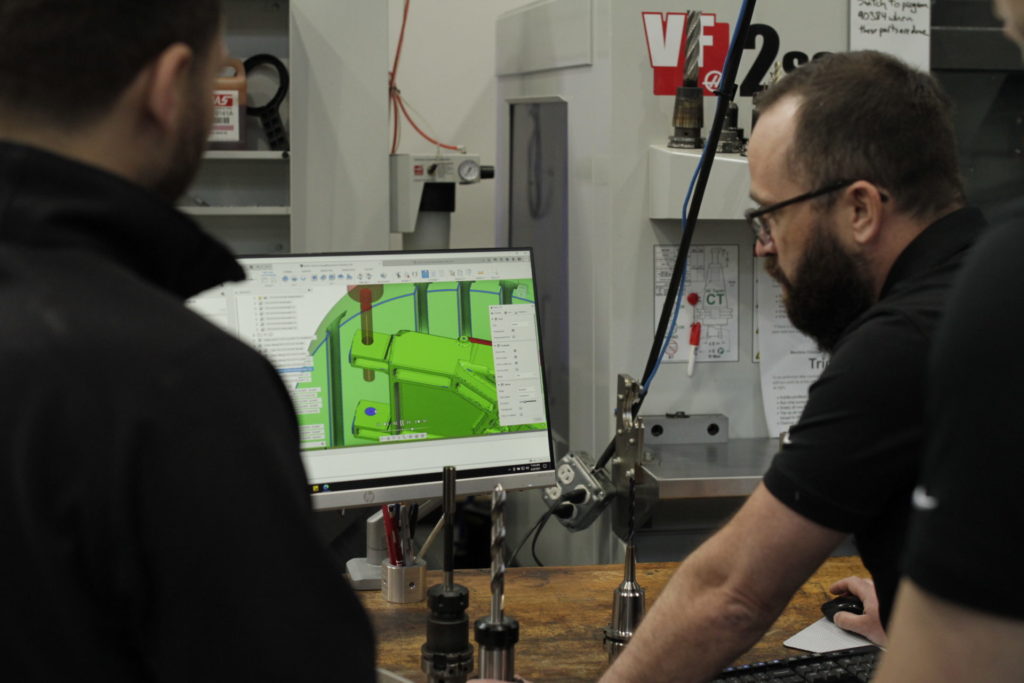

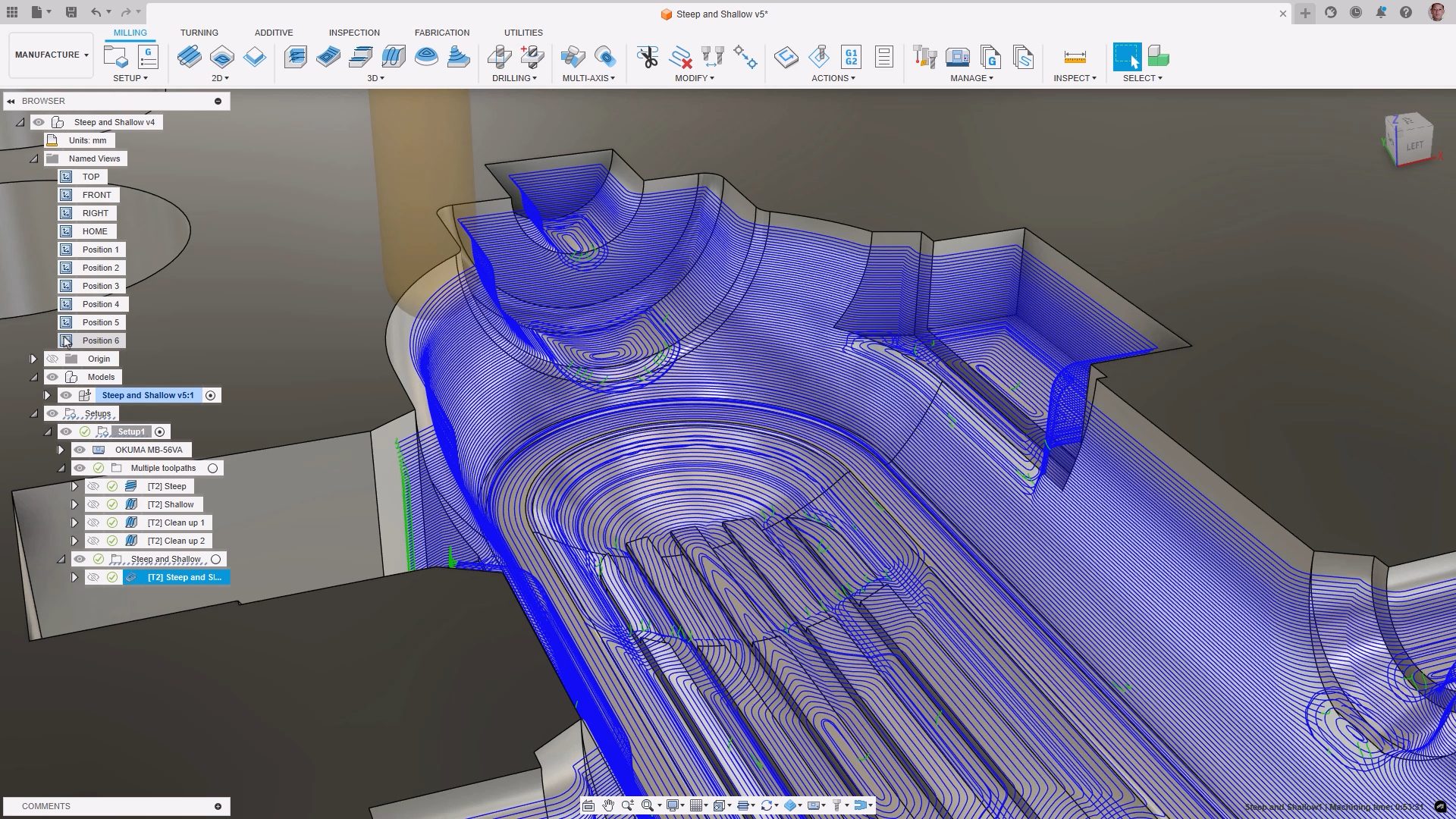

Achieve Faster, Better, and More Cost-Effective Manufacturing with Fusion

Fusion for Manufacturing helps you machine faster, finish better, and spend less with advanced toolpaths, automation, and integrated data management and collaboration. Speed, quality, and cost-effectiveness are more important than ever for manufacturers. Autodesk Fusion for Manufacturing is designed to help you meet these demands – unlocking new levels of efficiency and precision through advanced…

Advanced Manufacturing

-

What is CNC Machining? How Does CNC Machining Work?

What is CNC machining? In this detailed article, we'll explore what CNC machining is, its origins, and how it works.

Advanced Manufacturing

-

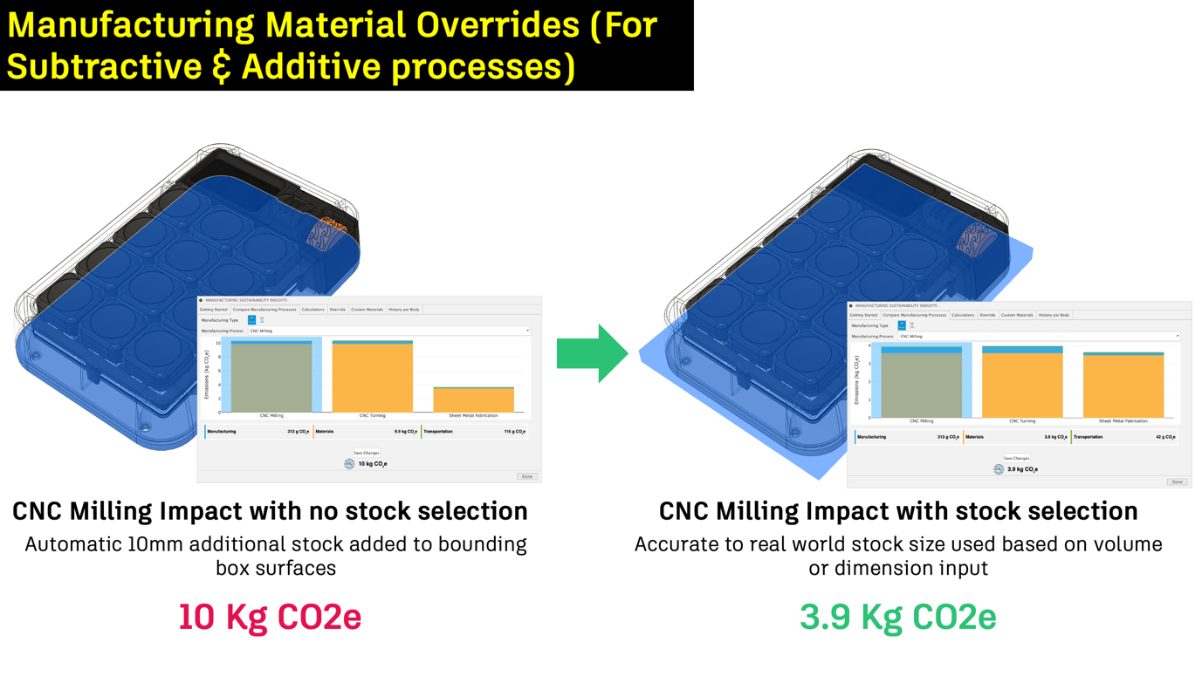

Advancing the Future of Sustainable Design with MSI — Now with New Features to Drive Smarter Decisions

Autodesk’s MSI V2 for Fusion boosts sustainable design with precise material overrides, hybrid process analysis, custom materials, and easy CSV exports, helping designers assess carbon impact. MSI add-on for Fusion At Autodesk, we’re committed to empowering designers with tools that make sustainability an integral part of the design process. The Manufacturing Sustainability Insights (MSI) add-on…

Advanced Manufacturing

-

How Can We Change Preconceived Notions About Manufacturing Careers?

Today's manufacturers are innovators, creators, designers, and critical thinkers, and they're creating the world we'll be living in tomorrow.

Advanced Manufacturing

-

HSMWorks to Fusion: Your Guide for a Smooth Transition

Transitioning from HSMWorks to Fusion is simple, offering compatibility with existing workflows and enhanced features for more efficient and advanced manufacturing solutions. As of March 25th, 2025, HSMWorks is no longer be available as a Fusion entitlement for new subscribers. But don’t worry—HSMWorks will continue to receive support until its end-of-life on March 25th, 2028.…

Advanced Manufacturing

-

Understanding 5-Axis Machining with Autodesk Fusion

Explore how 5-axis machining with Autodesk Fusion gives product designers greater precision and flexibility.

Advanced Manufacturing

-

Machinist Math Basics: Shop Mathematics & Conversion Tricks

Machinists have to use math on a daily basis to succeed. Here are a few ways to make mathematics a little easier on machinists.

Advanced Manufacturing

-

Breaking Free from Legacy Tools: The Fusion Revolution

Autodesk Fusion makes it easy to leave legacy tools behind, combining design, data, and manufacturing in one agile, cloud-powered platform.

Manufacturing

-

Accelerate Custom Automotive Design and Manufacturing with Autodesk Fusion

Learn how Autodesk Fusion streamlines the automotive design process to help your team move faster, reduce errors, and deliver better products.

Manufacturing

-

How to Use the Renishaw Fixturing and Styli Add-In for Autodesk Fusion

The Renishaw Fixturing and Styli Add-In for Autodesk Fusion streamlines the process of creating inspection fixtures and toolpaths, integrating Renishaw components and styli, and simplifying procurement with detailed assembly instructions and direct ordering capabilities. Digital transformation is changing the landscape of the manufacturing industry. Power players are coming together to leverage decades of expertise, drive…

Manufacturing

-

Drilling Into Automated Hole Recognition With Autodesk Fusion for Manufacturing

The automated hole drilling feature in Autodesk Fusion for Manufacturing simplifies CAM programming, reduces errors, and improves part quality.

Advanced Manufacturing

-

Exploring the Turning Capabilities of Autodesk Fusion for Manufacturing

Learn how the turning capabilities in Autodesk Fusion for Manufacturing provide a set of operations that optimize toolpaths and more.

Manufacturing

-

Autodesk Fusion for Manufacturing: Revolutionizing the Manufacturing Industry

Autodesk Fusion for Manufacturing is a comprehensive, cloud-based solution that integrates CAD, CAM, CAE, and PDM tools. Learn how this invaluable asset can help to streamline workflows, reduce costs, improve product quality, and foster innovation. In today’s fast-paced manufacturing environment, efficiency, precision, and innovation are paramount. In this article, we’re going to provide an overview…

Advanced Manufacturing

-

Exciting News from RAPID+ TCT 2025: Autodesk and Renishaw Collaboration!

Discover the seamless integration of Renishaw’s advanced additive manufacturing solutions with Autodesk Fusion, unlocking optimized settings and enhanced workflows for metal 3D printing. Explore new capabilities and the "Renishaw for Fusion" add-in at RAPID+TCT 2025.

Advanced Manufacturing