& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

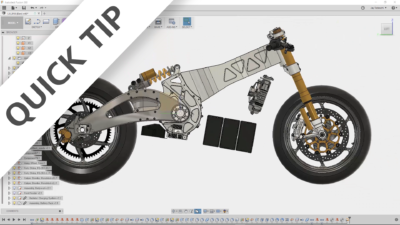

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

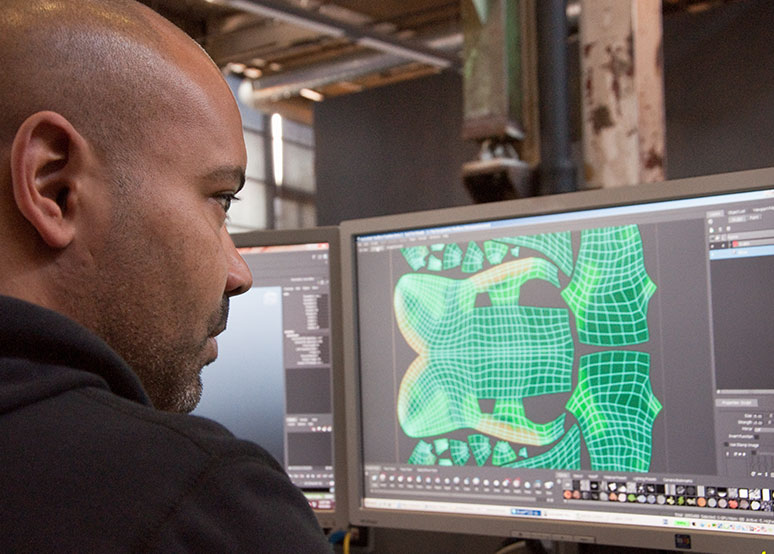

Computer-aided design changed the engineering realm just a few decades ago. The latest change to the tools available to engineers is the full integration of computer-aided manufacturing (CAM) into CAD programs. Let’s take a look at the biggest benefits that a CAD/CAM integrated workspace brings us as engineers. One thing that CAD did when it first was implemented…

Advanced Manufacturing

A look at how one mold manufacturer has embraced new manufacturing technology, unlocked the full potential of its workforce and become the dominant supplier in its field. Article by Clinton Perry, PowerMill Product Marketing Manager Today’s mold manufacturers are under pressure. Yep, it’s a shock revelation, right? Your end customers demand, even expect, to see…

Advanced Manufacturing

Image Source The days of affordable rapid prototyping and instantaneous production are upon us, but how have they changed the manufacturing industry as a whole? Initial hype around the 3D printing industry had everyone believing that they would be able to print whatever they want in their own home. While this is true, it isn’t…

Advanced Manufacturing

If you’ve ever taken shop class in high-school or watched an episode of how it’s made, you probably have some idea how lathes and other metalworking machines function. As technology and computers have improved over the years, a new high-precision computer controlled manufacturing technique called CNC machining has spawned. CNC machines, or computer numerically controlled…

Advanced Manufacturing

When was the last time your 3D CAD tool “aided” your design? Sure, the software enabled you to document an already determined outcome, maybe validated an instance of a design for strength, or even allowed you to convert a 3D object into those wonderful 2D views, and of course they updated when the model changed.…

Advanced Manufacturing

Human creative freedom has always been limited to two fundamental restrictions; the capabilities & limitations of the tools available to make objects, and a solution domain limited to the creativity of individuals. Take for example the development of software for a self-driving car, but apply that solution to a horse drawn carriage. Of course, neither…

Advanced Manufacturing

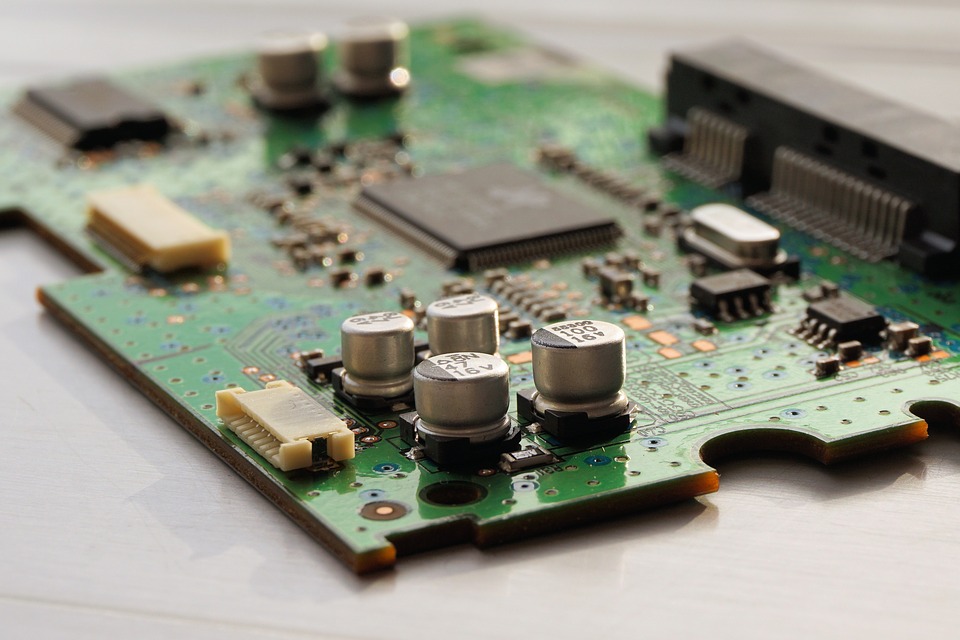

Image Source Additive manufacturing isn’t only limited to parts manufacturing, rather it is beginning to transform how electronics engineers manufacture circuits. When examining the realms of additive manufacturing within the constraints of electronics, there are 2 distinct production methods. There are 2inkjet-stylele printing techniques used to produce circuit boards. Typically, this method involves a printhead…

Advanced Manufacturing

Design for manufacturability is a proactive process used to maximize the design of components for the intended manufacturing process. Let’s take a look at how we can use this process can be improved or eliminated with the use of additive techniques. Looking over the typical manufacturing processes of machining, casting, injection molding, and forming, we…

Advanced Manufacturing

Image Source: Wikipedia The concept of a digital twin in manufacturing is one that has grown out of increasing connectivity. It’s a concept that allows manufacturers to monitor a product’s performance in real time using a digital model that responds identically to the real world product. As Industry 4.0 continues to drive forward the manufacturing…

Advanced Manufacturing

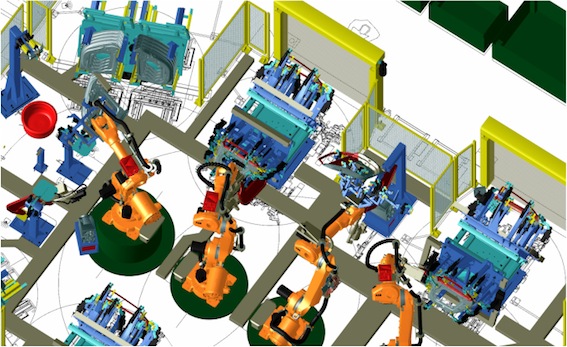

Today’s factories are easy to envision as futuristic-seeming hives of automation, where industrial robots mimic the movements and, seemingly, the intentionality of human workers. Today’s robots are not only working faster and more reliably than their human counterparts but also performing tasks beyond human capability altogether, such as microscopically precise assembly. But many of those robots…

Advanced Manufacturing

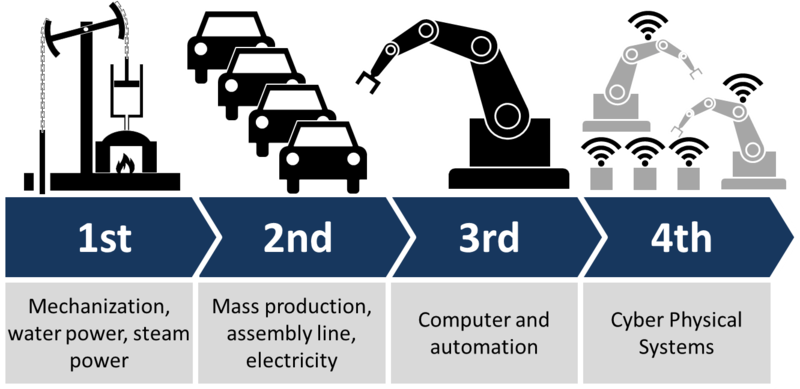

Image Source: Wikimedia The global manufacturing industry is looking to the future now more than ever. Manufacturing specific technologies are advancing at a rapid rate bringing on Industry 4.0 making the time for innovation now. This idea of a connected manufacturing environment has been around for many years, but it seems that constant innovation in recent…

Advanced Manufacturing

Image Source: Flickr The manufacturing skills gap is a very real problem facing the US manufacturing sector and industries abroad. Smart factories and robotics have become a key aspect of the fourth industrial revolution, set to bring about Industry 4.0, but humans are still and will continue to be a big part of the picture.…

Advanced Manufacturing

CAM is the future, so it becomes unequivocally important to discuss the future of CAM. Let’s take a look at the ways in which CAM is changing in order to accommodate the future of manufacturing How CAM is Evolving The industry just 5 years ago involved a lot of stress between disciplines. Engineers designed and…

Advanced Manufacturing

Product design has evolved over the years to include much more than just designing a 3D model. Controlling part revisions, collaboration, analysis, light weighting, drawings and more are now just some of the tasks in product design. Tools for product design have become better with increased functionality and interoperability with each other. Unfortunately, for many…

Advanced Manufacturing

Additive manufacturing has taken off in recent years, but two main barriers to entry still remain. Start up cost for purchasing machines is one major hurdle for smaller manufacturers, however, this hurdle is slowly coming down. The far more hindering barrier to additive adoption is that of speed. For most mass manufacturing applications, additive manufacturing…

Advanced Manufacturing

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.