CNC (Computer Numerical Control) machining is an advanced manufacturing technology that utilizes computer systems to control machine tools, providing a way to automate tasks that traditionally required manual labor, such as cutting, milling, drilling, and turning materials. This process has revolutionized manufacturing by making it possible to produce complex parts with incredible precision, repeatability, and efficiency. As industries have become more technologically advanced, CNC machining has become an indispensable tool in the production of parts used in everything from aerospace to medical devices.

How CNC works

The CNC process involves three main components:

- Machine tool: A physical machine, such as a lathe, milling machine, or router, that performs the material removal or shaping tasks.

- Computer system: A computerized control system that reads and executes the machining instructions.

- Programming instructions: These are typically written in a programming language like G-code or M-code. These commands tell the machine how to move and what actions to perform to create the part.

CNC machining begins with the creation of a digital model of the part using CAD (Computer-Aided Design) software. This model is then converted into a series of machine-readable instructions, which control the movement of the cutting tool. The tool interacts with the raw material to remove excess material, resulting in a precisely crafted part. This approach allows for exact duplication of complex parts, regardless of how intricate the design might be.

Types of CNC machines

CNC machines come in various forms, each suited to specific applications. The choice of machine depends on the type of material and the desired end result. Here are some common types of CNC machines:

1. CNC milling machines

Milling machines are among the most versatile CNC tools. They use rotary cutters to remove material from a stationary workpiece, making them ideal for shaping flat surfaces, slots, and intricate geometries. A standard 3-axis milling machine controls movements along the X, Y, and Z axes. However, more advanced machines can have up to 5 axes, enabling them to produce highly detailed, complex parts with ease.

2. CNC lathes

CNC lathes are specialized for shaping cylindrical or conical parts. The workpiece rotates while a cutting tool shapes it. CNC lathes are used for operations like turning, facing, and drilling, making them ideal for manufacturing parts like screws, shafts, and other symmetrical components. These machines are widely used in automotive, aerospace, and industrial manufacturing.

3. CNC routers

CNC routers are ideal for working with softer materials such as wood, plastics, and aluminum. They are primarily used in applications like cabinetry, signage, and other woodworking projects. CNC routers typically have 3-axis control, but they can also be equipped with 4 or 5 axes for more intricate designs.

4. CNC plasma cutters

CNC plasma cutters use a high-temperature plasma jet to cut through electrically conductive materials, such as steel, stainless steel, and aluminum. These machines are often used for heavy-duty applications, where precision is essential, but speed is also a factor. Plasma cutting is faster than traditional methods, such as laser cutting, especially for thick materials.

CNC machining process overview

The CNC machining process consists of several key stages, each essential for ensuring parts meet exact design specifications. Here’s a structured breakdown of these critical phases:

1. Design phase (CAD)

The process begins with the Computer-Aided Design (CAD) stage, where engineers create a digital 3D model of the part. This model defines the precise geometry, dimensions, and tolerances required for production.

- Purpose: To visualize and refine the part before manufacturing.

- Key tasks:

- Creating a digital 3D model with precise geometry and tolerances.

- Testing and adjusting the design to minimize errors.

- Outcome: A finalized design that is ready for manufacturing.

2. Manufacturing phase (CAM)

Once the CAD model is complete, it moves to the Computer-Aided Manufacturing (CAM) stage. CAM software converts the design into machine-readable instructions, such as G-code or M-code.

- Purpose: To prepare the CNC machine for efficient and accurate production.

- Key tasks:

- Selecting tools and generating toolpaths.

- Setting feed rates and spindle speeds.

- Planning and organizing machining operations.

- Outcome: Detailed instructions for the CNC machine to execute.

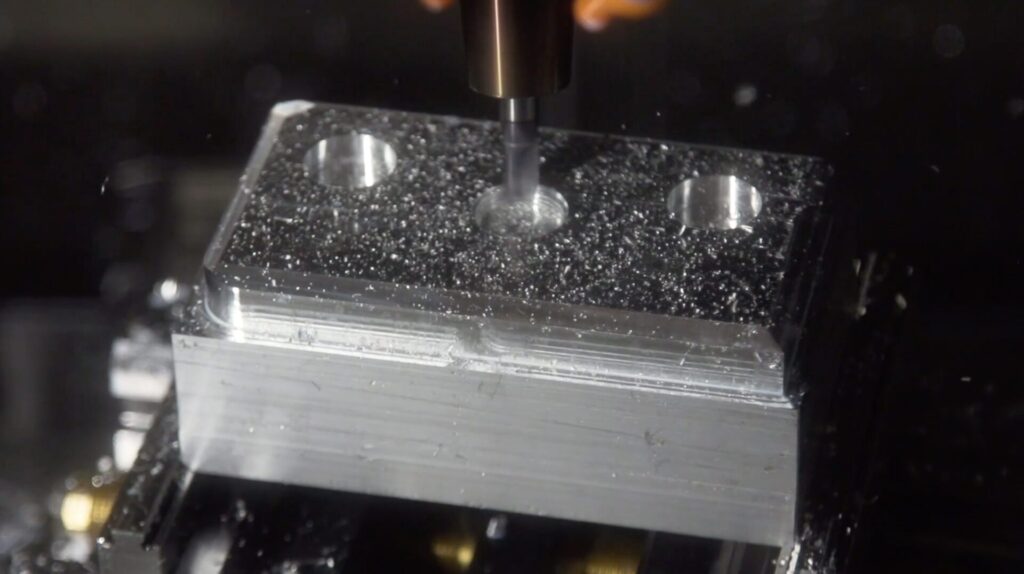

3. Machining phase

During the machining phase, the CNC machine follows the programmed instructions to cut, shape, or drill the material. This process often involves multiple passes to gradually achieve the final shape.

- Purpose: To execute the manufacturing process and produce the part.

- Key tasks:

- Shaping the material incrementally based on design complexity.

- Automatically adjusting cutting tools according to instructions.

- Outcome: A high-precision part with the desired geometry.

4. Finishing and inspection phase

After machining, the part undergoes finishing processes like deburring, polishing, or coating. It is then inspected to ensure it meets design specifications.

- Purpose: To finalize the part and verify its quality.

- Key tasks:

- Applying finishing processes for improved aesthetics and functionality.

- Measuring and checking dimensions against tolerances.

- Outcome: A completed part that meets all quality and performance standards.

CNC materials and tooling

CNC machining is compatible with a diverse range of materials, each offering unique advantages depending on the application.

Metals

Aluminum is a lightweight, easy-to-machine metal, commonly used in automotive and aerospace industries for parts where weight reduction is essential. Steel, known for its strength and durability, is widely used in structural and industrial applications due to its resilience under heavy loads. Titanium, valued for its lightweight and corrosion-resistant properties, finds extensive application in aerospace and medical industries where material longevity and reliability are critical.

Plastics

Acrylic, often chosen for its transparency, is commonly used in creating display cases or light covers. Nylon, known for its durability and impact resistance, is frequently found in mechanical components such as gears or bearings, where it can withstand stress and friction.

Composites

Carbon fiber is both lightweight and extremely strong, making it suitable for high-performance applications, such as in sports equipment and aerospace components where material strength and weight reduction are priorities.

Tooling in CNC

The selection of appropriate cutting tools plays a crucial role in the efficiency and quality of CNC machining. End mills are primarily used in milling operations to cut and shape materials, while drills are essential for creating holes across various materials. Lathe tools are specifically designed for turning operations on CNC lathes, enabling precise shaping and finishing of cylindrical parts. Each tool choice impacts the machining process’s accuracy, speed, and overall quality.

Advantages of CNC machining

CNC machining offers numerous advantages over traditional manufacturing methods, making it a preferred choice across various industries.

One of its most notable benefits is its high precision and accuracy. CNC machines can achieve exceptionally tight tolerances, often within a thousandth of an inch. This level of precision is crucial in industries such as aerospace, medical devices, and automotive manufacturing, where even minor deviations can affect safety or performance.

Another significant advantage is the consistency and repeatability that CNC machining provides. Once programmed, these machines can produce identical parts consistently, whether it’s the first piece or the thousandth. This capability ensures uniformity, making CNC machining ideal for mass production where maintaining quality is critical.

CNC machining also offers remarkable flexibility. These machines can work with a wide range of materials and adapt quickly to various parts and designs. This versatility makes them suitable for both prototyping and large-scale production, allowing manufacturers to switch between tasks effortlessly.

Finally, CNC machining excels in speed and efficiency. By automating much of the manufacturing process, it significantly reduces production time. With the ability to operate continuously, often 24/7, CNC machines enable faster turnaround times and increased productivity. This automation not only boosts output but also shortens lead times, making CNC machining an efficient and cost-effective solution for a broad array of applications.

This combination of precision, consistency, flexibility, and efficiency positions CNC machining as a cornerstone of modern manufacturing.

CNC machining applications

CNC machining has found applications in a broad array of industries due to its versatility and precision:

1. Aerospace

In aerospace, CNC machining is used to create critical components such as turbine blades, engine parts, and structural elements for aircraft. The ability to produce parts with tight tolerances and lightweight materials makes CNC machining a key technology in aerospace manufacturing.

2. Automotive

The automotive industry relies heavily on CNC machining for parts like engine blocks, transmission components, and custom vehicle modifications. CNC machining’s precision ensures that these components meet safety and performance standards.

3. Medical

The medical field uses CNC machining for producing medical instruments, prosthetics, implants, and surgical tools. CNC’s ability to work with biocompatible materials like titanium and its precision in crafting complex shapes are critical in medical manufacturing.

4. Electronics

In electronics manufacturing, CNC machining is employed to create enclosures, brackets, and components that house sensitive electronic circuits. The high level of precision ensures that parts fit together seamlessly, protecting internal components from damage.

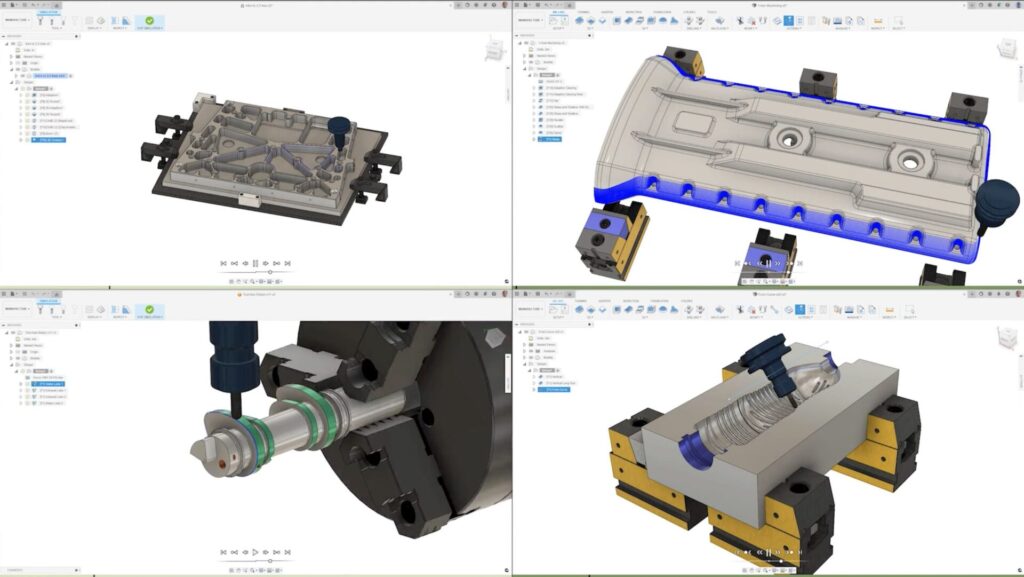

CNC machining and Autodesk Fusion

CNC machining has become one of the most imperative technologies in manufacturing today and thus can be used effectively to produce very accurate and complicated parts with limited human intervention. Autodesk Fusion’s integration of CAD, or Computer-Aided Design, with CAM, Computer-Aided Manufacturing, provides powerful means for smoothing the workflow associated with CNC machining in Autodesk Fusion.

Key features of Autodesk Fusion for CNC machining

Integrated CAD/CAM environment

Fusion combines CAD and CAM capabilities, enabling seamless transitions from designing parts to generating machining toolpaths. Changes in design automatically update in the CAM environment, eliminating errors and speeding up workflows. This integration minimizes data translation issues and accelerates the transition from design to production.

Toolpath generation and optimization

Fusion’s CAM module generates toolpaths based on 3D geometry, supporting strategies like 2D contours, 3D milling, drilling, and turning. Users can fine-tune feed rates, cutting speeds, and tool selection to optimize for different materials. These features enhance machining precision, reduce production time, and deliver superior surface finishes while minimizing tool wear.

Machining simulation

Fusion simulates the entire machining process, providing a visual representation of tool movements, material removal, and potential errors like collisions. This allows users to adjust toolpaths before production, reducing the need for physical prototypes, lowering material waste, and mitigating operational risks.

Adaptive clearing

High-efficiency roughing strategies in Fusion’s adaptive clearing feature ensure consistent tool engagement and rapid material removal. This approach shortens roughing times, prolongs tool life, and reduces costs on cutting tools.

Multi-Axis machining

With support for 3, 4, and 5-axis CNC, Fusion enables the creation of complex geometries in a single setup. This capability simplifies machining intricate shapes, reduces the number of setups needed, and saves time while ensuring alignment accuracy.

Post-processing

Fusion’s customizable post-processors convert toolpaths into G-code compatible with various CNC machines. This ensures broad compatibility, simplifies code generation, and reduces the chances of programming errors.

Cloud-based collaboration

Fusion’s cloud platform facilitates real-time collaboration, allowing team members to access, edit, and share projects seamlessly. This centralization improves version control and ensures better communication among distributed teams.

Autodesk Fusion has truly made CNC machining an integrated solution where design, toolpath generation, simulation, and manufacturing all combine into one. Such a holistic approach towards the entire work cycle accelerates the process right from concept to final production. With its robust toolpath optimization, simulation, multi-axis machining support, and cloud collaboration, Fusion stands tall as a game-changing tool in the hands of any manufacturer in his quest to improve precision, reduce costs, and enhance productivity.

Where the creation, simulation, and machining environment demands unparalleled value in industries like aerospace, automotive, and medical devices, precision and quality stand between life and death. Makers using Autodesk Fusion to handle CNC machining capabilities will be able to stay competitive in such an aggressive market while keeping their production processes optimized for speed, accuracy, and efficiency.