& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

8 min read

This post is also available in: Italiano (Italian) Deutsch (German)

You know what they say about fundamentals: learn them first, and you’ll remember them forever. The same holds true for CNC machine programming. Even as new manufacturing technologies unfold, the fundamentals for how parts are machined with a CNC program will stay with you forever.

In this article, we’ll be talking about the core component of every CNC program – G-code.

Manufacturers all around the world use CNC programming to control a machine’s tools to produce parts. At the heart of this automated manufacturing process is a set of instructions that tells a CNC machine where – and how – to move. These instructions are called G-Code.

G-code was first established in the 1960s by the Electronics Industry Association (EIA). While the official language was documented as RS-274D, you’ll hear everyone refer to it as G-code. Why? Many of the words, or individual pieces of code, that make up this machine-based language start with the letter G.

While G-code is supposed to be a universal standard, you’ll find that many CNC machine companies have developed their own unique flavor. We’re all be eating ice cream at the end of the day, but a Haas might be strawberry flavored, and a Tormach might be chocolate flavored. Because of this difference in G-code flavors, it’s imperative to understand how your own machine uses G-code.

Why the difference in G-code flavors? It really comes down to the capabilities of each machine. Take one machine that can process a coordinate system rotation based on probe inputs. You’ll need a set of G-code commands that can enable or disable this rotation. Another machine without this adjustment capability won’t require that G-code.

When in doubt, always refer to your CNC machine’s documentation as you work through the rest of this article. We’ll be walking through the basics, but you never know if your machine might have taken a slightly different path to the same end destination.

The G-code standard was published back in the days when machines had small amounts of memory. Because of this memory limitation, G-code is an extremely compact and concise language that might almost seem archaic at first glance. Take, for example, this line of code:

G01 X1 Y1 F20 T01 M03 S500

In this single line, we’re giving the machine a series of instructions:

Multiple lines of G-code like these combine to form a complete CNC program. Your CNC machine will then read the code one line at a time from left to right and top to bottom, like reading a book. Each set of instructions is on a separate line or a block.

The goal of every G-code program is to produce parts in the safest and most efficient way possible. To achieve this, you’ll typically find G-code blocks arranged in a particular order like this:

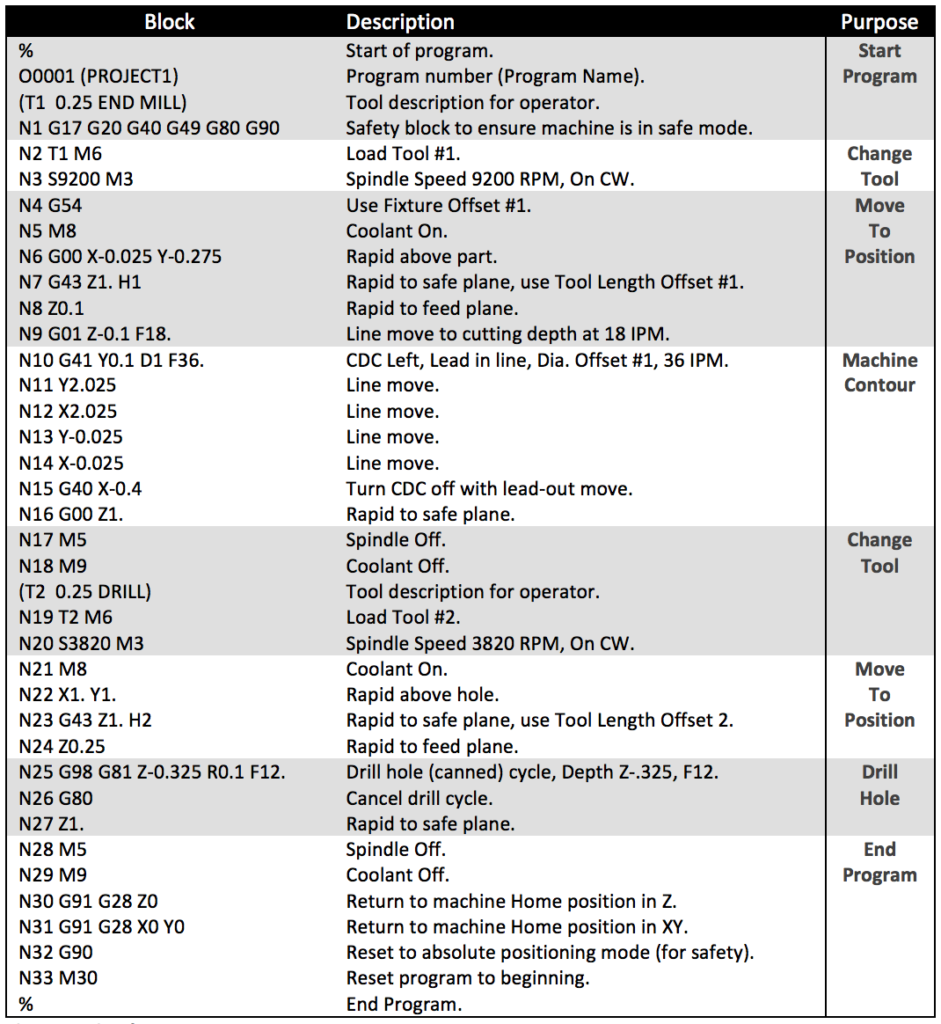

This flow is a simple program using only one tool for one operation. In practice, you will typically rinse and repeat steps 2 through 9. For example, the G-code program below encompasses all of the code blocks above with repeating sections where needed:

Like other programming languages, G-code can repeat an action indefinitely until stopped. This looping process uses modal code, which acts until you either turn it off or modify it with another modal code. For example, M03 is a modal code that will run a spindle indefinitely until you tell it to stop with M05. Now, wait a second. That word (remember: a word is a little piece of code) didn’t start with a G, but it’s still G-code. Words that start with an M are machine codes, and they turn machine functions like coolant, spindle, and clamps on or off. I’ll list some common ones in the next section, but you can find a list of your machine’s M-codes in its documentation.

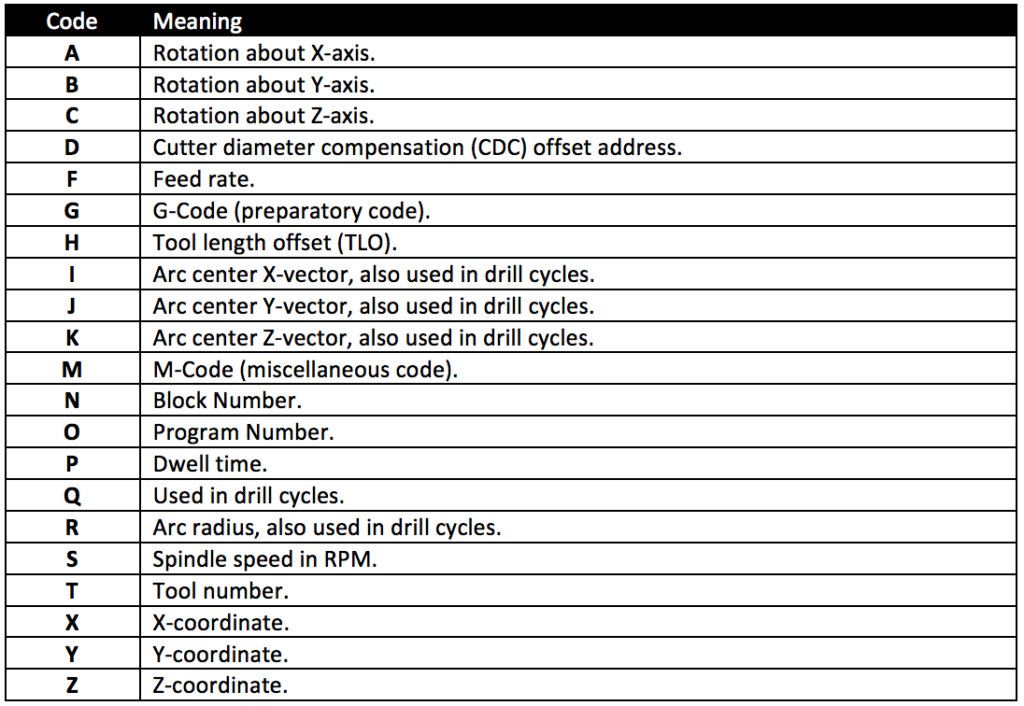

G-code also includes a complete list of address codes. You can think of these as the dictionary for G-code that defines particular behaviors. Address codes begin with the letter designation, like G, and then with a set of numbers. For example, X2 defines an X-coordinate address code, where 2 is the value on the X-axis to move the machine to.

The complete list of address codes includes:

Several special character codes can be added to a G-code program. These are typically used to start a program, comment out text, or ignore characters and include:

G & M-codes will make up the bulk of your CNC program. Codes that begin with G prepare your machine to perform a specific type of motion. The most common G codes that you’ll encounter time and time again in every CNC program include:

G0 – Rapid Move

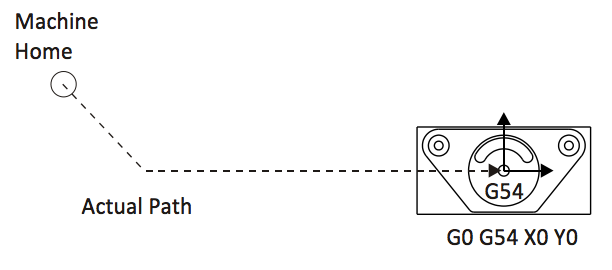

This code tells a machine to move as fast as possible to a specified coordinate position. G0 will move the machine axis by axis, meaning that it will first move along both axes and finish the move on whichever axis is not in positions. You can see an example of this motion in the image below:

G1 – Linear Move

This code tells a machine to move in a straight line to a coordinate position with a defined feed rate. For example, G1 X1 Y1 F32 will move the machine to coordinates X1, Y1, at a feed rate of 32.

G2, G3 – Clockwise Arc, Counter-clockwise Arc

These codes tell the machine to move in an arc to a coordinate destination. Two additional coordinates, I and J, define the arc’s central location as shown below:

G17, G18, G19 – Plane Designations

These codes define what plane an arc will be machined on. By default, your CNC machine will use G17, which is the XY plane. The other two planes are shown in the image below:

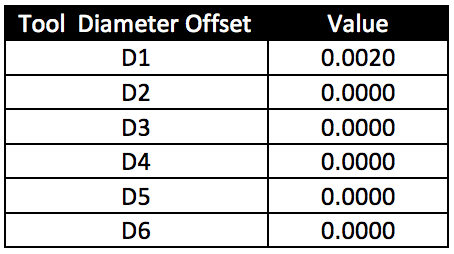

G40, G41, G42 – Cutter Diameter Compensation

These codes define the cutter diameter compensation, or CDC, which allows a CNC machine to position its tool to the left or right of a defined path. A D-register stores the offset for each tool.

G43 – Tool Length Compensation

This code defines the length of individual tools using a Z-axis height. This allows the CNC machine to understand where the tip of a tool is in relation to the piece it is working on. A register defines the tool length compensations, where H is the tool length offset and Z is the tool’s length.

G54 – Work Offset

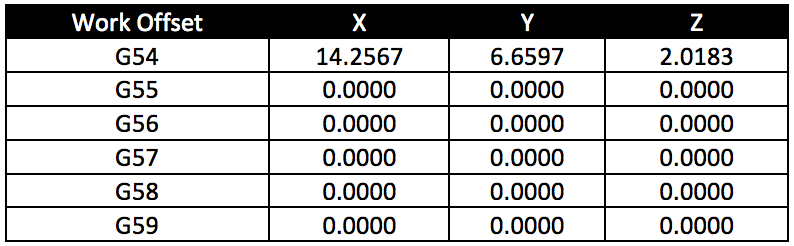

This code is to define a fixture offset, which determines the distance from a machine’s internal coordinates to the datum on a workpiece. In the table below, only G54 has an offset definition. However, you can program multiple offsets if a job requires machining multiple parts at once.

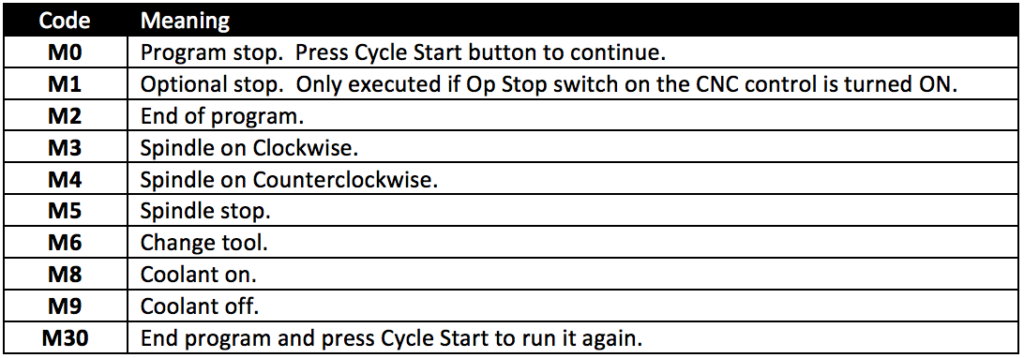

M-codes

M codes are machine codes that might differ between CNC machines. These codes control functions on your CNC machine like coolant and spindle directions. Some of the most common M-codes include:

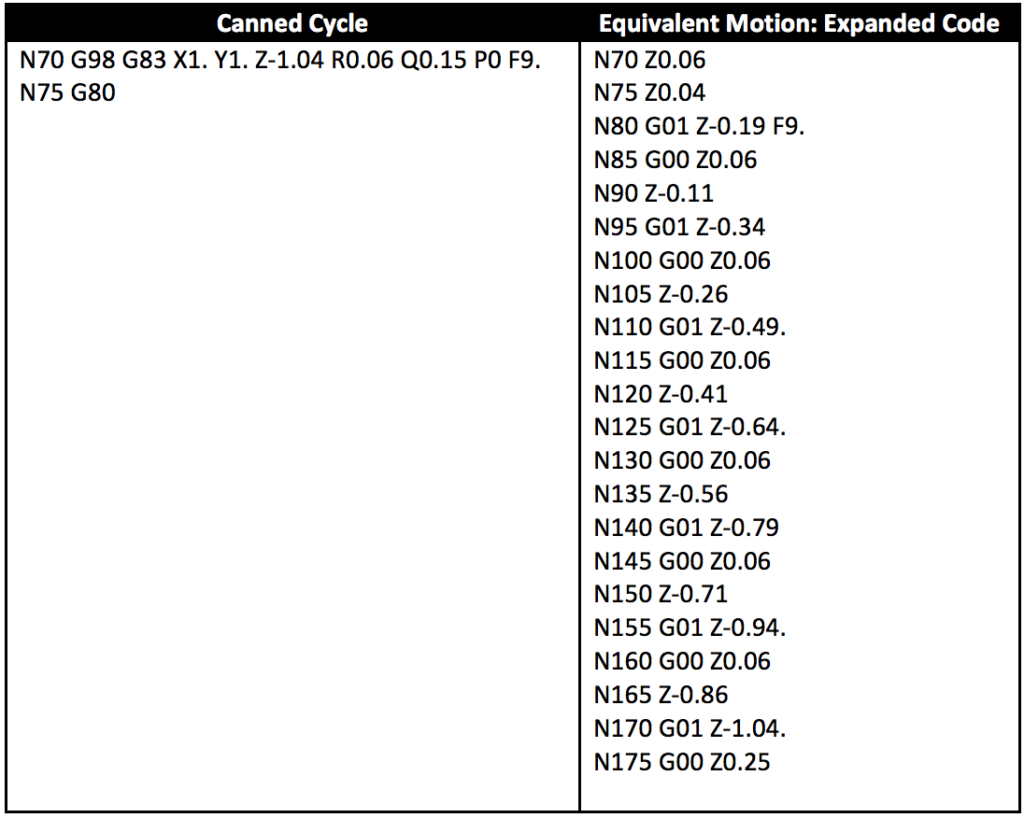

The last aspect of G-code to touch on is canned cycles. These are similar to methods or functions in computer programming. They allow you to perform a complicated action in only a few lines of code without having to type out all of the details.

Take, for example, the canned cycle below. Here we are telling the CNC tool to create a hole with a peck drill in only two lines of code on the left. This same action takes over 20 lines of regular G-code.

G81 – Simple Drill Cycle

This cycle will make a hole by plunging to a specific Z-axis coordinate and then retracting. Programming this cycle requires a depth, feed rate, XY coordinates, and plane to drill on.

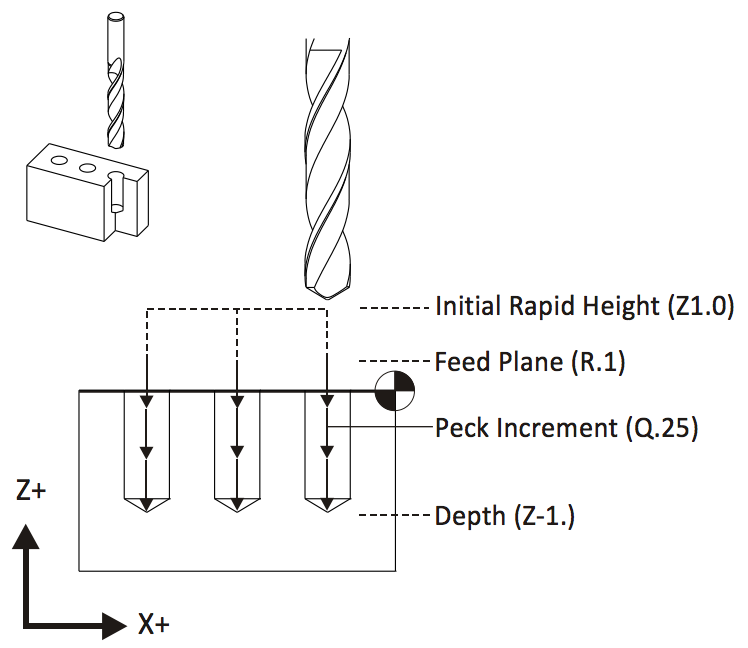

G83 – Peck Drill

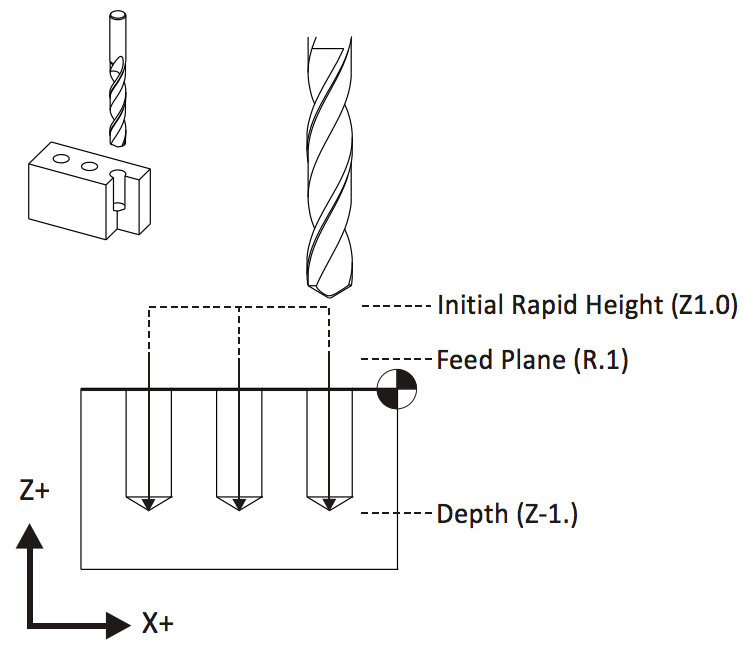

This cycle is for quickly drilling deep holes. A tool will first drill a defined distance and then retract, which clears any material out of the hole and allows coolant to flush away chips. This cycle’s simplest implementation requires an initial height, feed plane, peck increment, and depth.

G98 – Return to Initial Rapid Height

This cycle will retract a tool to a clearance plane between holes, which helps to avoid clamps. Programming this cycle requires an initial height and feed plane to drill on.

Even if you never end up writing your own CNC program by hand, understanding G-code’s fundamentals will give you a leg up in your CNC programming career. The core behavior remains intact across manufacturers, even as the actual G-code differs slightly. At the end of the day, you’re combining coordinates, feed rates, and a set of definable actions to move a tool and machine a part successfully.

Some guides recommend memorizing the most common G and M codes. While this might work, practice makes perfect! Continuously use and refresh your G-code fundamentals throughout your career and they’ll stick with you. Here’s a quick quiz to see where you’re at.

Ready to put your CNC programming and G-code knowledge to work? Try Fusion 360 today!

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!