Data is increasingly becoming the backbone of competitive manufacturing operations in today’s digital era.

Integrating data analytics into manufacturing processes is a central pillar of digital transformation, enabling businesses to enhance precision, efficiency, and adaptability significantly. This strategic shift towards data-centric operations is about leveraging new technologies and fundamentally transforming how manufacturers operate and compete in a rapidly evolving marketplace.

Data analytics empowers manufacturers to make informed decisions based on accurate, real-time information, optimizing every aspect of the production process. From improving supply chain logistics to fine-tuning production lines and enhancing product design, the impact of data is profound and far-reaching.

This transformation is reshaping the manufacturing landscape, opening up new opportunities for innovation and efficiency that were previously unattainable. Here are a few key ways data-driven strategies are revolutionizing the industry as part of the digital transformation journey.

Production planning

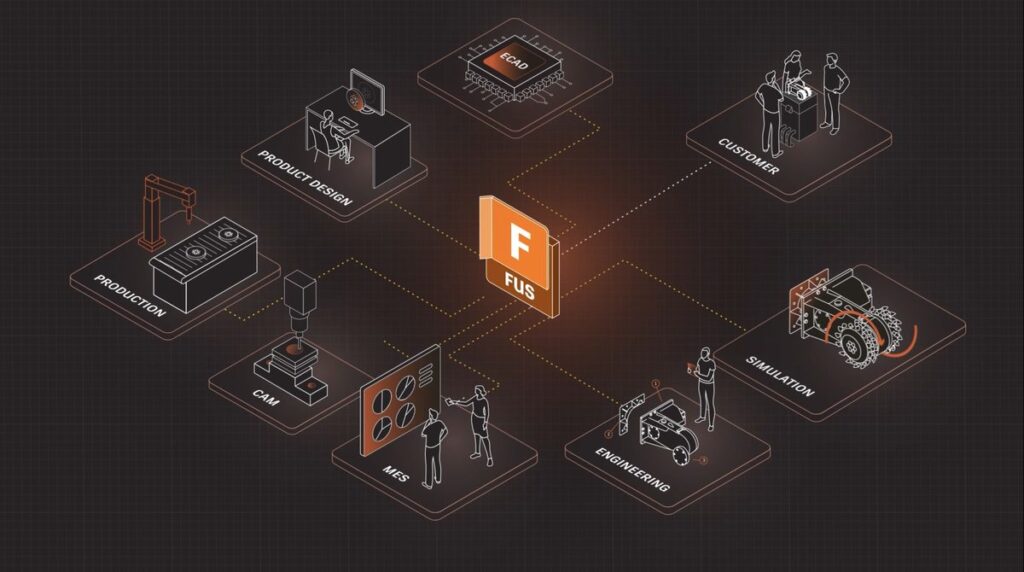

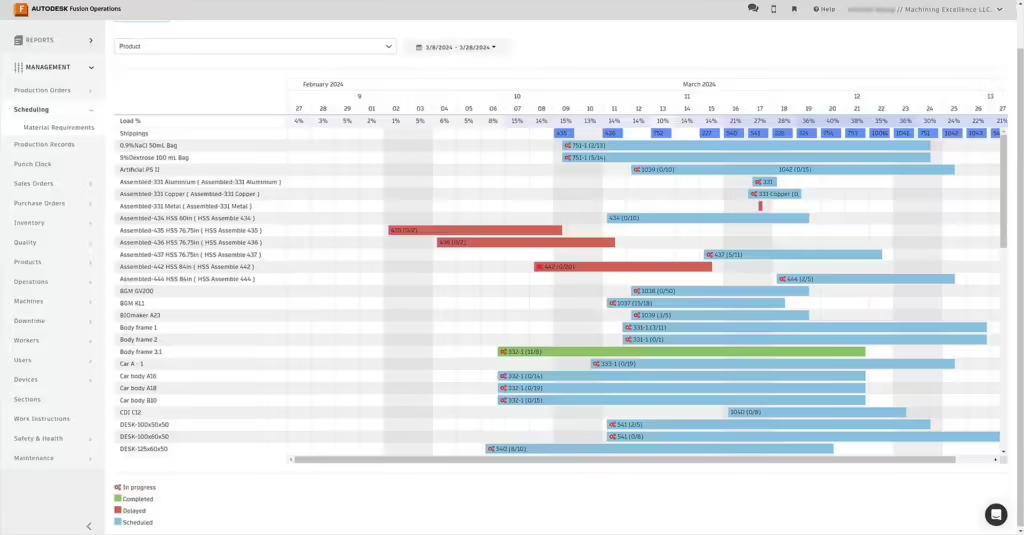

By leveraging the capabilities of Autodesk Fusion Operations, Fusion Manage, and Fusion, manufacturers can optimize their production schedules using historical data and real-time inputs. This approach maximizes resource utilization and effectively minimizes downtime.

Within this integrated platform, production planning tools facilitate the adjustment of production volumes based on factory and production floor insights, ensuring that manufacturing output precisely aligns with demand without leading to overproduction. This strategic use of connected data within the Fusion ecosystem helps streamline operations and improve manufacturing efficiency.

Process optimization

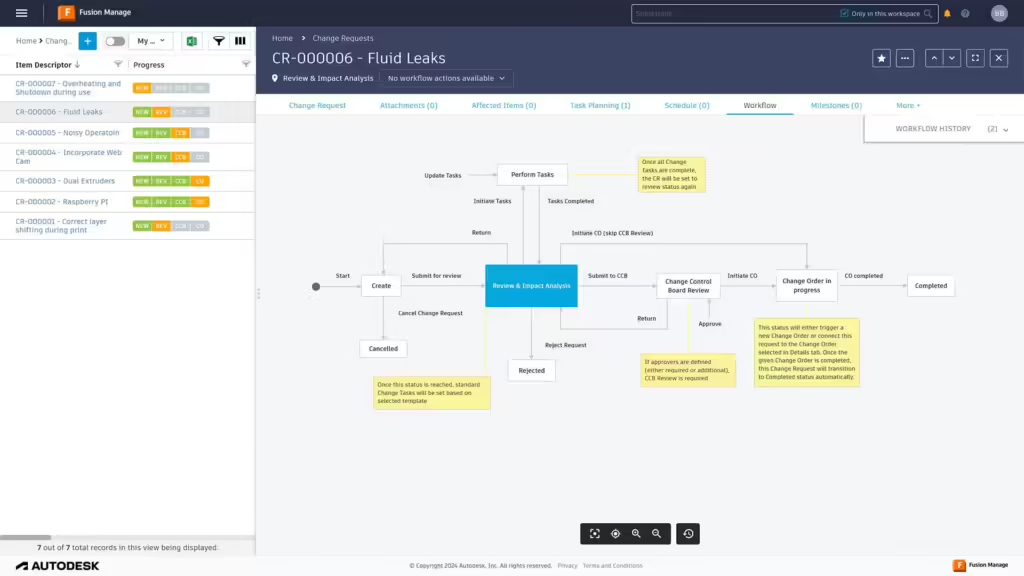

Fusion Manage optimizes machine uptime by streamlining production strategies with robust data and process management. It enhances product portfolios with real-time access to specifications and streamlines innovation through formal idea reviews.

Connected requirement management ensures products meet market expectations while organized new product introductions reduce delays. Quality management processes improve product designs and traceability, and efficient change management provides full activity traceability for KPI analysis. By integrating comprehensive data handling and process optimization, Fusion Manage significantly boosts operational efficiency and reduces downtime.

Design revision histories

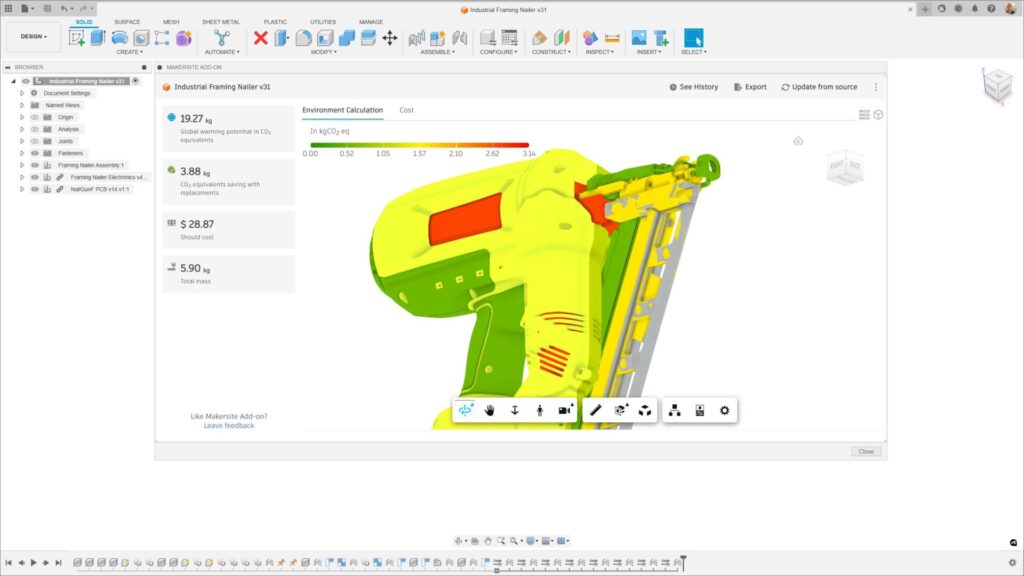

In Fusion, design revision histories are crucial for enhancing the collaborative and iterative design process. By meticulously tracking every change made to product designs, Fusion enables manufacturers to swiftly revert to earlier versions if newer designs fail to meet expectations, ensuring continuous improvement and optimal performance.

Key features that enhance this capability include:

- Assembly Concurrency: This feature allows multiple teams to work together within the same design environment in real time. Assembly concurrency ensures that all changes are synchronized across the team, allowing for immediate feedback and necessary adjustments, which enhances the iterative process.

- Fusion Team: Fusion Team facilitates project management and communication through a browser-based interface. It enables distributed teams to engage in discussions, share insights, and manage projects remotely, ensuring effective collaboration and accessibility for all stakeholders, regardless of location.

- API Integration: Fusion’s robust API capabilities extend functionality by enabling integration with communication platforms like Slack. Changes in the design history can automatically trigger Slack notifications, keeping the team updated instantly and enhancing responsiveness to revisions.

Benefits of connected data

Integrated data systems transform manufacturing operations by enhancing decision-making, increasing operational efficiency, and enabling deeper customization of products. Here’s how:

- Enhanced Decision-Making: Integrating data from various sources (such as supply chain, production floor, and market trends) provides a comprehensive view of operations. This holistic perspective aids in making informed decisions that align closely with business goals and market demands.

- Operational Efficiency: Connected data systems automate the flow of information across different departments. This synchronization reduces communication lag time and accelerates the pace at which projects move from design to production.

- Product Customization: With access to detailed customer data and preferences, manufacturers can tailor products to meet specific market segments or individual customer needs, enhancing customer satisfaction and loyalty.

Scenarios: Leveraging Real-Time Data

How can this be seamlessly integrated into your existing processes?

Fusion and Fusion Operations

Powertrust‘s goal is to deliver renewable energy systems that provide sustainable, safer options for everyone. It currently produces new solutions for generators and electricity storage for residential, agricultural, and industrial use. The company has always relied on Autodesk Fusion as its product development tool, but it eventually needed a solution for tracking its production process as well.

Fusion Operations and its compatibility with Fusion was the ideal solution for Powertrust to streamline and track production. “We have hundreds of parts, sub-components, and raw materials to track for our products,” says Philipp Schütte, Production Manager, Powertrust. “Before we only had serial numbers for some main parts. It’s a huge deal for us to have serial numbers attached to everything. We can track everything with Fusion Operations.”

Fusion Manage

Evatec is a company that makes film production tools for the semiconductor, optoelectronics, and photonics industries. Its solutions are modular and flexible so they can quickly develop tailored solutions for each market. “Quality is one of our most important topics across the company,” says Klause Mundle, Head of Product Lines, Evatec. “A cloud-based PLM system integrates all of our partners. Everyone sees the most up-to-date information for the best decision-making.

A data-driven future with Autodesk Fusion

Autodesk Fusion underscores the crucial role of data at the core of modern manufacturing processes. By harnessing real-time and integrated data, businesses undergo a transformative shift that moves beyond mere operational enhancement to a complete redefinition of their manufacturing strategies. This evolution is essential for adapting swiftly to today’s market’s complexities and rapid changes.

Integrating digital workflows through Autodesk Fusion revolutionizes design and production and sets a new industry standard. Manufacturers gain the ability to respond dynamically to market demands, enhance productivity, and drive innovation. In doing so, they establish themselves as leaders in digital transformation, ready to meet future challenges with agility and advanced technological integration.

This strategic approach demonstrates that by placing data at the forefront, Autodesk Fusion empowers businesses to compete and lead in the evolving industrial landscape.