This post is also available in: English (Englisch)

Have you taken the new additive manufacturing space in Fusion 360 for a spin yet? If not, you’re missing out! Here are seven reasons why you should give it a try.

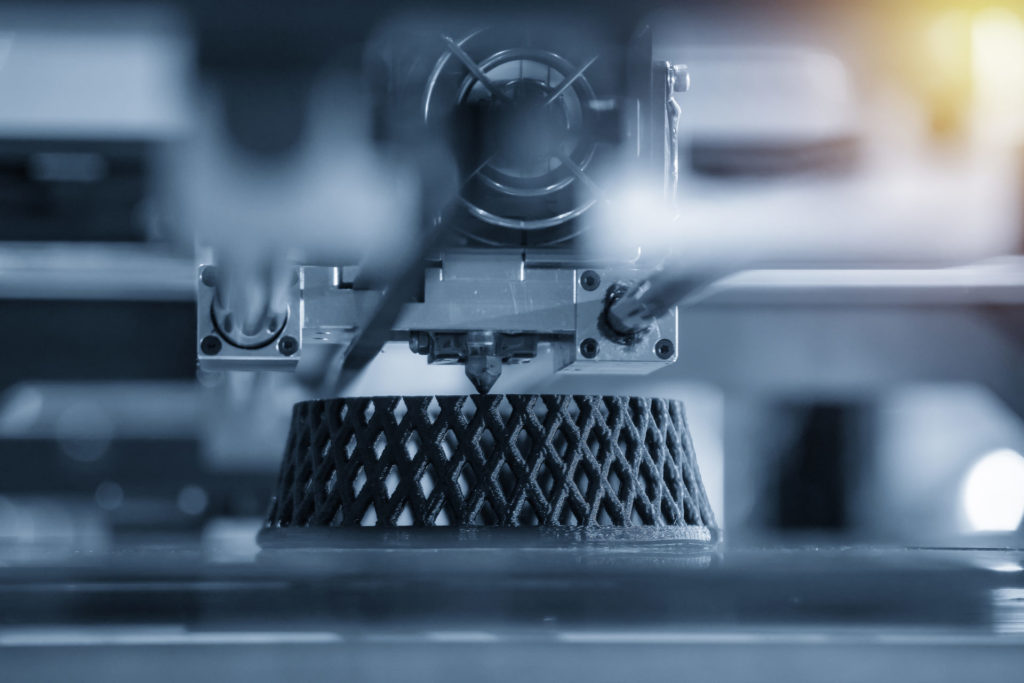

We recently added additive manufacturing capabilities to the Fusion 360 manufacturing workspace. You might be wondering why, especially since Fusion 360 has been able to export STLs since launch. We thought it would be helpful for us to walk you through seven reasons why we believe the additive manufacturing space in Fusion 360 is worth using over your standard slicer.

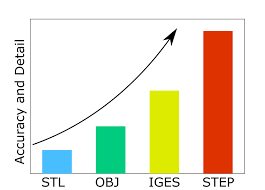

1. STLs Don’t Carry Manufacturing Data

STL’s are mesh files that have become the standard format for 3D printing. However, STL mesh data is the least accurate file type (out of STL, OBJ, IGES, and STEP). It technically does not carry any essential information for 3D printing. Additionally, STLs don’t carry one of the most critical factors to manufacturing: units. Slicer software relies on OBJ and STL historically because it is the most universally adopted export from nearly every CAD platform. With Fusion 360, you can create manufacturing data without building up an archive of STL files. You can just export the manufacturing G-code directly from Fusion 360.

2. Associative Design and Manufacturing Data

Current workflows that support STL export break the flow from design to manufacture, especially if you primarily use additive manufacturing for prototyping. STL files invite errors, as the process to stay up-to-date with them is entirely manual. In Fusion 360, your design data and manufacturing data are associative. This means that if you set up a part to print and need to change the design itself, any changes you make in the design space will propagate to the manufacturing space. There’s no need to set the file up again; you can just push that G-code out for printing.

3. 3MF Revolutionizes Additive Manufacturing

The difference between an STL and a 3MF is like the jump from a .BMP (shoutout to everyone old enough to remember those and MS Paint) to a PDF. A PDF can carry way more information, fonts are selectable, you can embed images and videos, and you can encrypt PDFs natively. 3MFs are the 3D printing equivalent. A 3MF can carry a lot more metadata than STLs. For example, elements like color and fidelity are much higher with 3MF.

The 3MF format is expanding continuously to carry more and more metadata relevant to 3D printing. Fusion 360 is 3MF compatible, so you can live in the present and not the past with STLs. Learn more about how 3MF carries lattice information here.

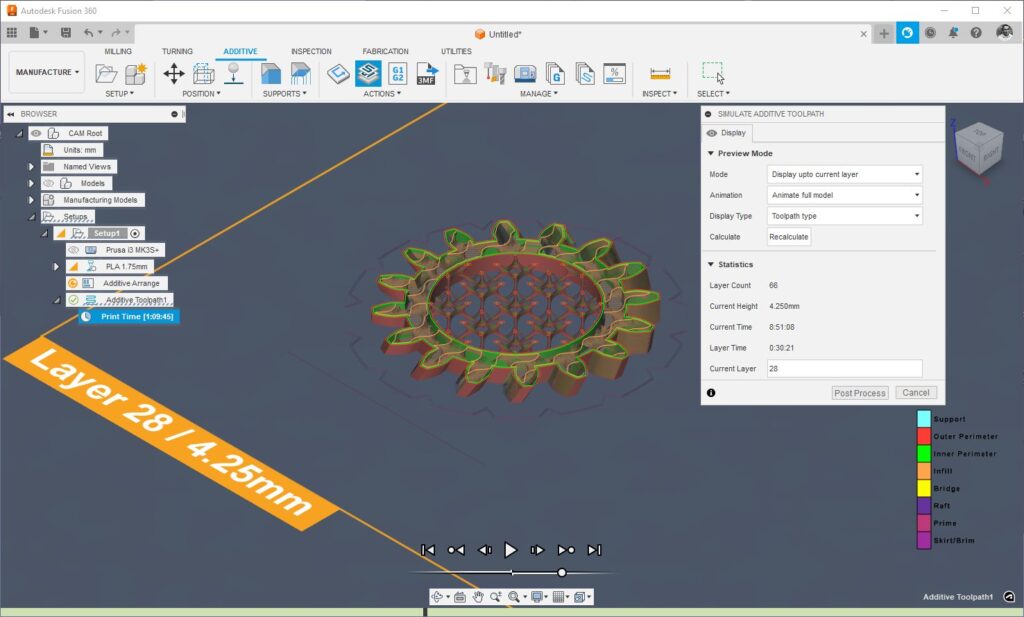

4. Get More Control Over Print Settings Than with Slicers

We’ve talked a lot about data management, but what about actual prints? Understandably, many people are anxious about moving away from a slicer. It’s something you’re familiar with, and your slicer offers a lot of settings. However, there’s no perfect slicer—that’s why there’s an entire industry for third-party slicers.

Fusion 360 gives you a lot more control over print settings than most slicers. It features more general print settings and control over your infill, shells, and printer behavior. It also includes options for custom post-processers that will give you granular control over your print settings.

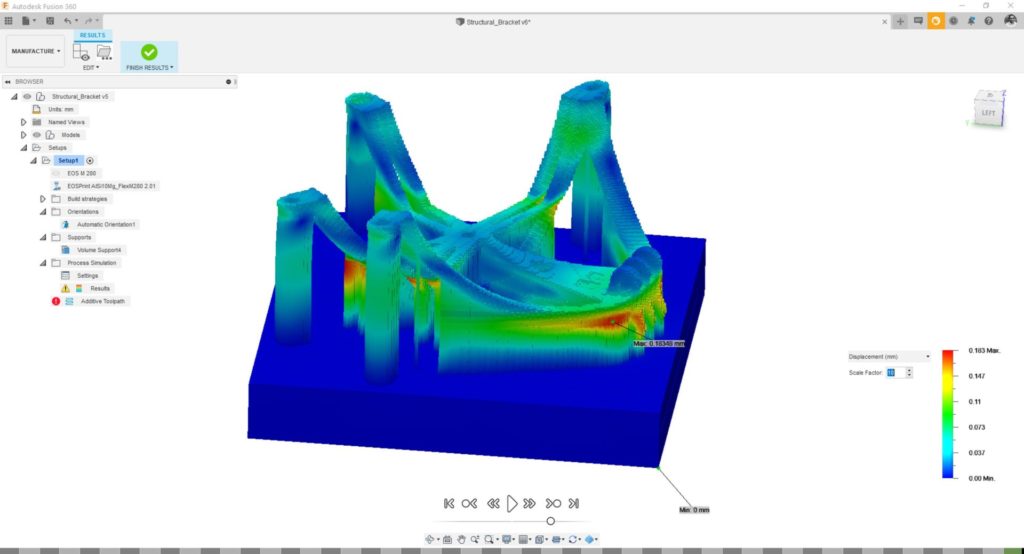

5. Fusion 360 Extensions Take Your Additive Capabilities Further

One of the best things about Fusion 360 is how the product is structured. The base product covers nearly everything you need to design, engineer, and manufacture almost anything. But sometimes, you need to do something specialized. Enter Fusion 360 extensions. Extensions give you access to specialized features, making your workflow more affordable and uninterrupted by extra product purchases.

Fusion 360 extensions give you access to DMLS (Direct Metal Laser Sintering) workflows and process simulation to see how your object will print. You can also create manufacturing models that will compensate for displacement caused by heat change with just one click. Fusion 360 extensions predict distortion and common print failures, such as recoater interference based on thermo-mechanical simulation.

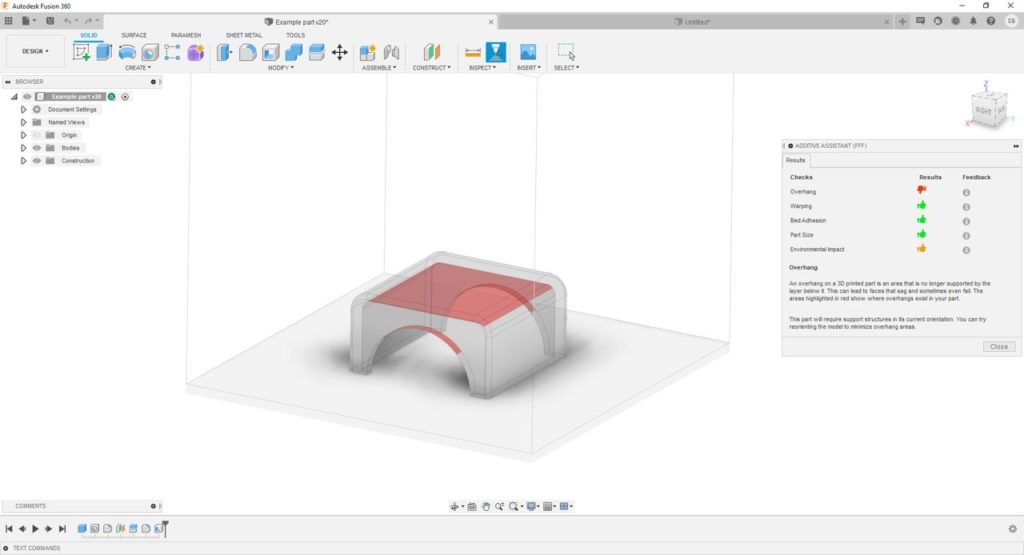

6. Avoid Common Mistakes with Additive Assistant

One of the great things about Fusion 360 is the app store. Of course the app store features plugins by third parties that want their products to talk to Fusion 360, but did you know that Autodesk staff also produce free apps?

One of the best tools available in the app store is the additive assistant. Whether you’re a beginner or a seasoned pro, we all make mistakes when prepping parts for printing. The additive assistant identifies potential issues that might occur in printing, highlighting where overhands are, where warp may occur, whether your part will have good bed adhesion, and more. It’s an essential tool to up your game and get the most out of your prints.

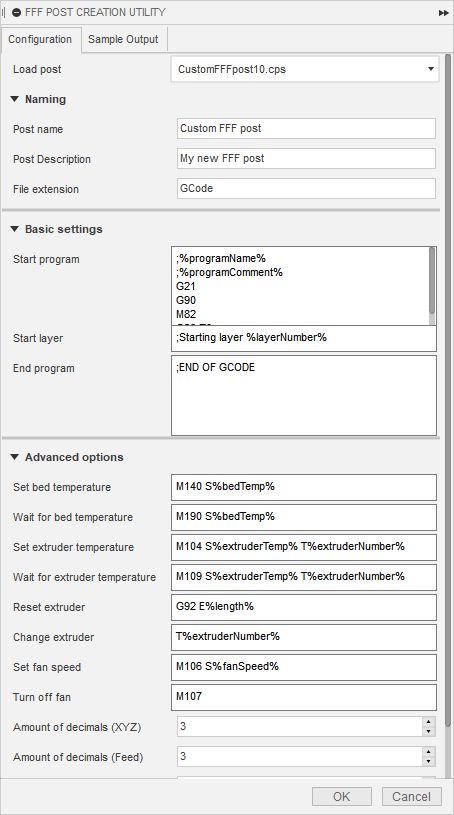

7. Customize Your Machine with Post Configurator

Another great app is the post configurator. We’ve already mentioned how you can get the most out of your printer using the additive manufacturing space in Fusion 360, including customizing post-processors. The FFF post configurator enables you to control functions you would typically punch in manually on the machine, like bed temperature, wait times during heating, fan speed, and more.

There you have it! Seven reasons why the additive manufacturing space in Fusion 360 is worth taking for a spin. Have you tried it out yet? Sound off in the comments and let us know what you think!