Direct modeling is a flexible CAD technique allowing designers to create and modify 3D models quickly without predefined constraints, ideal for concept design and rapid prototyping. Autodesk Fusion enhances this by enabling users to switch between direct and parametric modes, providing tools for both rapid modifications and detailed design work within a collaborative cloud-based platform.

Introduction to direct modeling

Direct modeling is a CAD technique that gives designers and engineers the power to create and modify 3D models quickly and intuitively. Unlike traditional parametric modeling, which relies on a history-based approach with defined constraints and relationships, direct modeling is more flexible and offers a user-friendly way to interact with 3D geometry. It’s particularly beneficial for concept design, rapid prototyping, and situations where speed and ease of use are top of mind. The power of Fusion is that you have the ability to switch between direct and parametric modes depending on where you are at in the product development process.

Key features of direct modeling

Intuitive interaction

Users can interact directly with the geometry of the model. Designers can push, pull, and drag features to reshape the model without concerning themselves about breaking predefined constraints or relationships. This makes it easier to explore different ideas and make quick modifications. For example, changing the shape of a part or adjusting the dimensions of a feature is effortless, allowing for a more fluid design process.

Flexibility and speed

Known for its flexibility, you’re not bound by a sequence of steps or a history tree. This is useful during the early stages of design, where ideas are fluid, and iterations are many. The ability to quickly implement changes can significantly speed up the design process and reduce time to market.

Ease of use

Direct modeling is easy to use for both beginners and experienced CAD users. Its user-friendly interface and straightforward approach make it easier for new users to learn and start creating models without a steep learning curve. This ease of use also encourages collaboration among team members with varying levels of CAD expertise.

Ideal for conceptual design

Quickly modify geometry without being constrained by a detailed history, allowing for greater creativity and exploration. Designers can iterate rapidly, testing different ideas and refining them based on feedback, leading to more innovative and well-thought-out designs.

Applications of direct modeling

Rapid prototyping

Direct modeling is widely used in rapid prototyping, where speed and flexibility are crucial. Designers can quickly create and modify models to test different ideas and iterate based on feedback. This process helps refine designs and identify potential issues early in the development cycle.

Reverse engineering

In reverse engineering, users can create digital models from physical objects quickly. By scanning an object and using direct modeling techniques, engineers can recreate the geometry and make necessary modifications without being constrained by a parametric history.

Industrial design

Industrial designers can develop aesthetic and ergonomic aspects of products. The ability to freely manipulate shapes and surfaces helps designers create visually appealing and functional designs that meet user needs.

Design exploration

Direct modeling provides a flexible platform for trying out different ideas. Designers can quickly iterate on concepts, evaluate various design alternatives, and make informed decisions based on visual feedback.

Direct modeling industry applications

Consumer electronics

Direct modeling is invaluable for developing innovative products quickly in the world of consumer electronics. Companies can create and test multiple iterations of a product, making sure that the final design meets user needs and preferences. This approach allows for rapid prototyping and testing, reducing time to market and increasing the chances of a product’s success.

Automotive

The automotive industry benefits significantly from direct modeling, particularly in the design and development of new vehicle components. Engineers can create and modify parts quickly, facilitating collaboration among different teams and suppliers. This flexibility allows for rapid iterations and adjustments, ensuring that the final design meets performance and safety requirements.

Aerospace

In the aerospace industry, direct modeling is used for designing complex components and assemblies. The ability to quickly modify geometry and test different design alternatives is crucial for developing high-performance parts that meet stringent safety and performance standards. It also facilitates collaboration between different teams and partners, ensuring optimal designs and efficient validation.

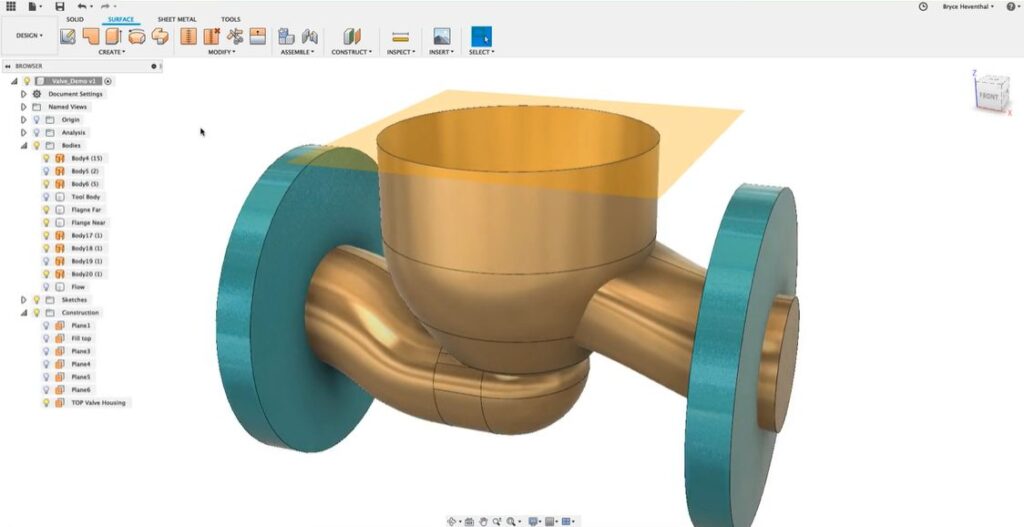

Autodesk Fusion: A comprehensive direct modeling solution

Autodesk Fusion offers a comprehensive set of tools that to meet various design needs. Fusion’s direct modeling tools let users quickly create and modify geometry, making it ideal for concept design and rapid prototyping. It also combines the benefits of direct modeling with powerful parametric capabilities, providing users with the best of both worlds. Its intuitive interface and cloud-based platform enable seamless collaboration and access to the latest design data from anywhere.