Distributed designs in Autodesk Fusion enable collaborative, real-time work on different parts or components of a project, enhancing efficiency and design flexibility through cloud-based synchronization. Let’s dive into how they work in Fusion and when and why to use them.

Designers coming to Fusion from other CAD systems will carry with them experiences that drive their expectations. In general, expectations are based on traditional Windows desktop-based CAD solutions where parts and assemblies are individual files distributed among folders on their hard drive.

While Fusion supports the concept of independent or externally referenced designs (xrefs), it’s not the default starting point. Understanding this upfront allows designers to make informed decisions on design methodologies and data structures to support the work required to build products in a collaborative environment.

Arriving in Fusion: Internal vs. External

When entering Fusion, it defaults to a garden path which creates internal components. This means that without choosing to create external designs, all the parts of the assembly are embedded in a single easy-to-manage design. This workflow allows designers to move quickly when building and manufacturing products. Eliminating the need to manage a large number of designs.

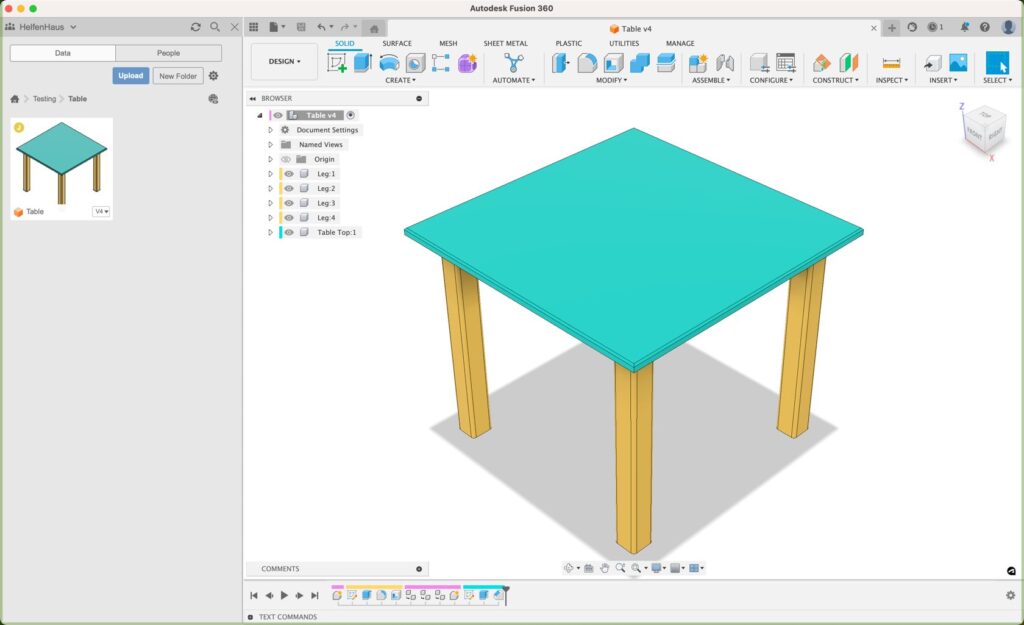

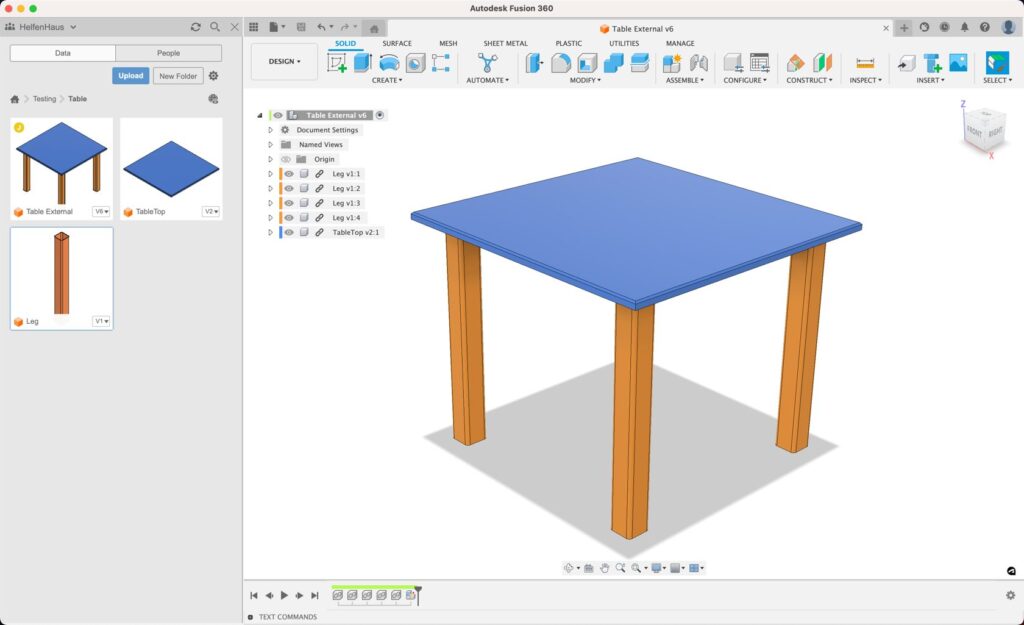

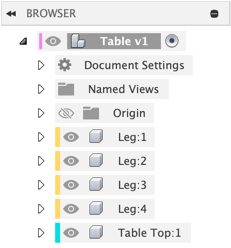

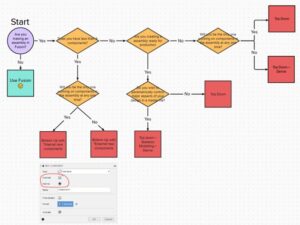

Let’s use a simple table assembly made with 4 legs and a tabletop to explain. The images below show the results of creating a table with all internal components and the same table with all external components for comparison. The images highlight where the data panel, browser, and timeline differ between internal and external components.

Data Panel

The data panel is a view into Fusion cloud storage. This is where projects, folders, and designs are stored.

Internal components

The table assembly and its components (legs/tabletop) are encapsulated in a single design. If edits to the assembly or components are required, they are made by directly opening the table design.

External components

The table assembly, leg, and tabletop appear as independent designs. Each can be opened and edited independently and easily reused in other designs.

Browser

The browser is the structured view of the timeline, and where sketches, components, bodies, construction geometry, and other items are surfaced for easy interaction.

Internal components

The browser shows each instance of a design in this assembly. Each instance has a location in the browser. It also displays the visibility icon, component type icon, component name, and instance number.

External components

The external designs appear similar but include a link icon to indicate external and a version number for the design.

Timeline

The timeline is a record of action taken to design, build, and develop a product.

Internal Components

Internal components embed the features and authoring intelligence for each component and the assembly actions in a single design with an integrated timeline.

External Components

External designs encapsulate the authoring intelligence (the features) of a part in an externally referenced design.

Editing a component in the context of an assembly using edit in place (EIIP) will expose the features of the component for editing.

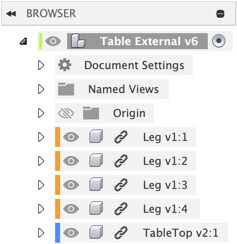

Distributed Designs in Autodesk Fusion: When to Use Them

Over time individuals often begin to collaborate with others and sometimes evolve into small teams. At the same time, projects tend to get bigger and a change in strategy is required to accommodate the expansion. Internal designs allow speed and flexibility with limited data management requirements, but design reuse and collaboration become more challenging.

Decision Map

Reduce Design Duplication

Individual designers will typically begin distributing designs after noticing design duplication in their first few projects. When using common hardware components (nuts, bolts, washers, etc..) across designs it quickly makes sense to store those in a common project shared for use across all projects.

- Shared Hardware Projects– including standard nuts, bolts, washers, etc.

- Shared Design Projects – including customized purchased components, brackets, mounting hardware, or any other custom design components applicable to several different designs.

Enable Collaboration

As designs get more complex and teams get bigger, methodologies, data structures, and strategies all start to shift toward workload distribution and management. When this happens, distribution expands beyond hardware to the assembly design where subsystems of a design are also distributed to support collaboration.

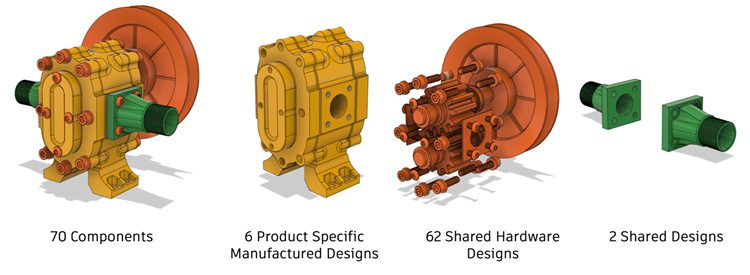

Distributed Designs in Autodesk Fusion: Why to Use Them

As organizations evolve toward a distributed model additional benefits are gained around design reuse, collaboration, concurrency, and more. Fusion includes several tools to help small teams work together on a design and the key to accessing these benefits is the distribution of designs.

Design Reuse

Creating shared libraries helps normalize design data and more efficiently manages change. Modification to a shared design in a single location will update a wide range of designs at once saving time and reducing the chance of errors.

The Fusion Fastener Library encourages distribution by creating a Fastners Project at the root of the hub as the common location for fasteners used across all projects.

Improved Collaboration

Distributing designs allows multiple designers to work on different areas of an assembly concurrently. Each subsystem may be built by a different designer, each working in their area of an assembly independently and concurrently.

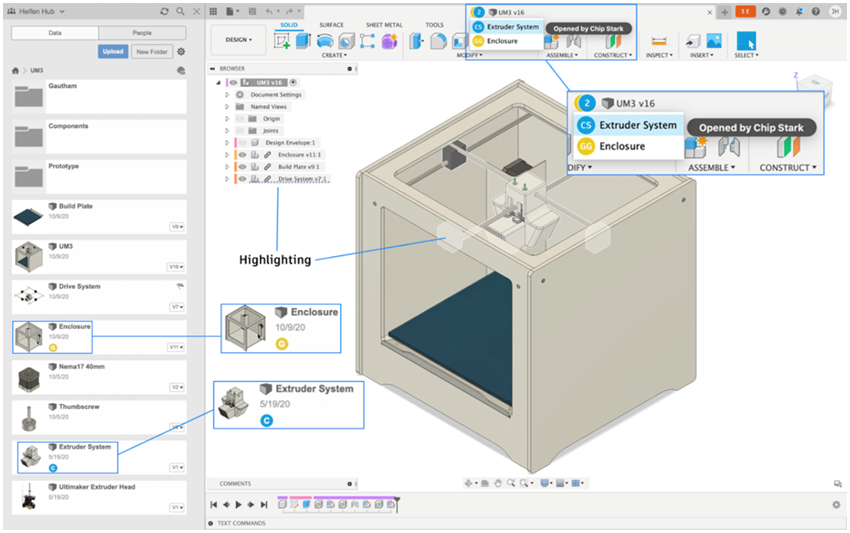

For example, if the product being designed were a 3D printer, the product may be distributed into subsystems like an enclosure design, a build plate design, and a spool management system. In this scenario, each sub-system could be designed and managed by an individual designer independent from the other systems.

Avatars & Design Reservations

Show who you are collaborating with and where they are working in relation to your area of interest, which allows you to prepare for possible change. Avatars appear on each design when others open for viewing or have a change in progress. Learn more here.