Learn the benefits of electronic design automation and how to leverage available technology as the demand for smart technology increases.

What is Electronic Design Automation?

Electronic Design Automation (EDA) refers to a subset of software tools and methodologies used to design, analyze, and verify electronic systems. EDA tools are critical in the design process, helping product development teams automate various tasks and improve efficiency. Overall, EDA tools are crucial in improving design efficiency, reducing time-to-market, enhancing design quality, and enabling the development of complex electronic systems. They are essential for meeting the demands of today’s technology-driven world.

What are the top benefits?

Electronic Design Automation (EDA) offers several benefits that enhance the design process and improve overall efficiency and quality. Some key benefits of EDA are:

- Increased productivity: EDA tools automate various design tasks, reducing manual effort and allowing designers to focus on higher-level design decisions. This leads to faster turnaround times and shorter design cycles.

- Design optimization: EDA tools provide advanced algorithms and analysis capabilities. These help optimize designs for factors such as performance, power consumption, area, and timing. This ultimately allows for more informed decision-making to achieve better system performance.

- Reduced errors and design iterations: EDA tools include simulation and verification capabilities allowing designers to validate their designs before fabrication. This helps identify errors, potential issues, and conflicts early in the design cycle.

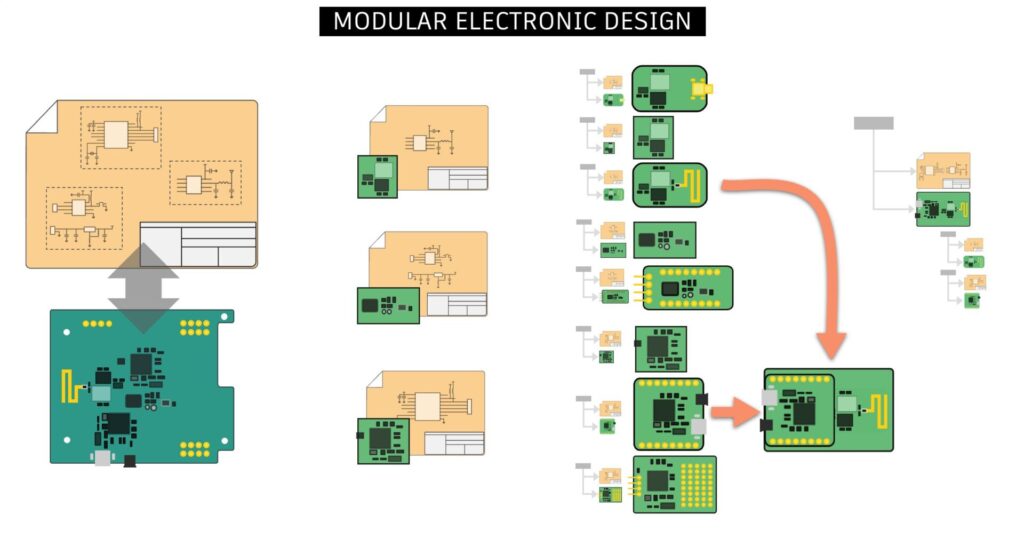

- Design reuse and modularity: EDA tools enable the creation and management of reusable design components, libraries, and intellectual property (IP) blocks. Designers can leverage existing modules, reducing development time, while allowing for design consistency and standardization.

- Collaboration and team productivity: EDA tools facilitate collaboration among product development teams, enabling designers and engineers to work on different aspects of a design simultaneously. These tools offer version control, design data management, and design collaboration.

- Design scalability: EDA tools can handle the complexities of modern electronic systems. This allows teams to work on large-scale designs with complex printed circuit boards (PCBs). They provide scalability to accommodate growing design complexities and enable the integration of third-party tools and technologies.

- Design for manufacturability: EDA tools assist in designing circuits that are manufacturable within the constraints of the fabrication process. They help identify and address manufacturing-related issues early in the design phase. Thus, reducing the likelihood of costly manufacturing defects and improving yield rates.

- Cost and time savings: By streamlining the design process, reducing errors, and optimizing designs, EDA tools can lead to significant cost savings. This is realized in terms of reduced development time, minimized design iterations, and improved overall product quality.

Electronic Design Automation technology

EDA encompasses a wide range of design activities, including:

- Schematic capture creates a graphical representation of the circuit using symbols and connecting them to form a circuit diagram.

- Simulation tools allow you to run virtual tests on the circuit to evaluate its behavior and performance under different conditions.

- Logic synthesis: Converting a high-level hardware description (e.g., in a hardware description language like VHDL or Verilog) into a gate-level representation.

- Placement and routing determine the optimal arrangement of components (placement) and establishes connections (routing) on a PCB or IC to minimize delays and optimize performance.

- Timing analysis allows you to evaluate the timing characteristics of a circuit to ensure that signals propagate correctly and meet desired performance criteria.

- Physical design verification allows you to check the layout of the circuit against various design rules and constraints to ensure manufacturability and reliability.

- Design for Test (DFT) incorporates features into the design that facilitate testing and fault diagnosis during manufacturing and operation.

- Design rule checking (DRC) verifies that the layout adheres to specific manufacturing rules and guidelines.

- Power analysis examines power consumption and optimizing circuit designs for energy efficiency.

- Formal verification uses mathematical techniques to prove or disprove the correctness of a circuit’s behavior.

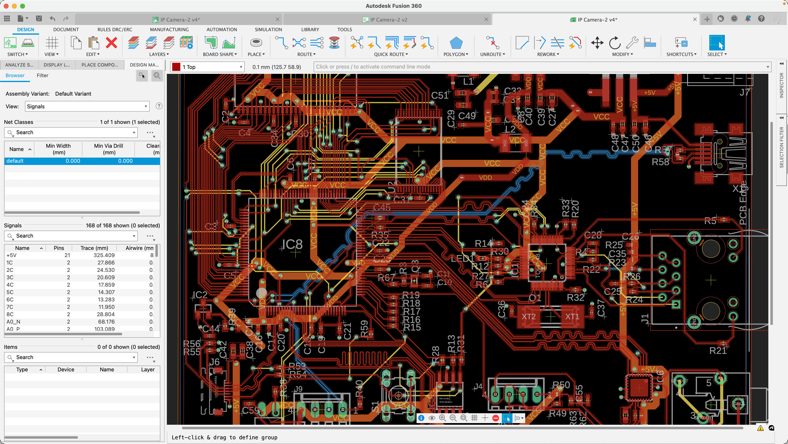

Autodesk Fusion 360 – Your Electronic Design Automation solution

Ready to get started with Electronic Design Automation? Start with a free 30-day trial of Autodesk Fusion 360 electronics today.