This post is also available in: Français (French) Italiano (Italian) Deutsch (German) 日本語 (Japanese)

Explore how design automation tools like parametric modeling, generative design, and automated modeling in Fusion 360 enable your team to grow smarter.

Businesses achieve increased revenue — the simplest measure of business growth — through additional sales, new product offerings, shorter lead times, and more. All of these types of growth strategies require some level of added capacity, or the ability to provide more goods and services. Traditionally, adding capacity would involve hiring new employees, investing in new equipment, or expanding physical facilities. An oft-overlooked method of adding capacity, however, is automation.

What is automation?

In the simplest sense, automation is a method to reduce human touchpoints in a workflow or process. In return, this frees up human resources to focus on other more important tasks. The end result is a net increase in capacity that directly translates to business growth if properly utilized. It is important, however, to avoid trying to leverage automation for tasks that aren’t well suited for it. Automation does require some base level of overhead for development, maintenance, and service. If one isn’t careful, it is entirely possible to yield a net increase in an effort to automate a task that was already a highly optimized human process.

Traditional design automation methods

For many years, two methods existed for adding a layer of automation in the product design process: custom software and spreadsheets. The former generally required a dedicated software team and was relegated to larger, established companies, while the latter was accessible to most smaller businesses in a position for growth. Spreadsheets allowed someone to enter parametric design characteristics and, through the use of formulas, produce a set of specifications to drive a CAD model. However, from this point on, the engineers still had to create CAD models by hand before passing them on to the rest of the team.

Though simplistic, this type of automation was an excellent first step toward efficiently capturing customer needs and minimizing the upfront workload for the designer. Teams could develop spreadsheets rapidly, they were easily maintainable, and they required minimal upfront investment.

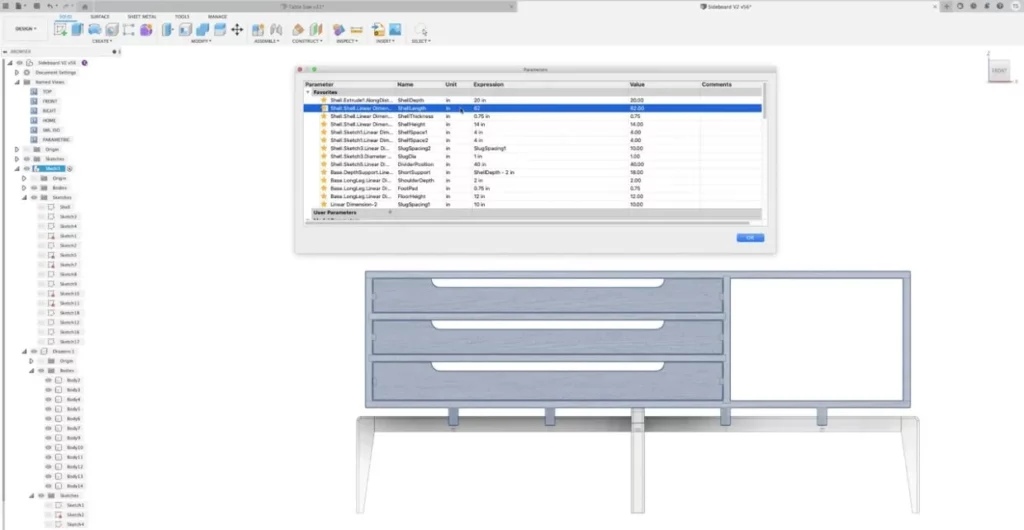

The next step: rules-based automation

The next evolution of automated design came from the integration of spreadsheet-like functionality into the CAD software itself. This became known as rule-based automation or parametric modeling. When teams wanted to create a customizable design, they could build variables and formulas into their 3D model. Then, when it was time to customize the design, the design would update in sync with any design changes.

Businesses that tailor a product or service to a particular customer’s requirements can still benefit hugely from incorporating parametric modeling into their CAD workflow. The tool enables them to create a custom design on the fly with minimal engineering overhead. This frees up resources, making them available to grow other aspects of the business. No additional work gets added to the CAD engineer’s plate, and overall business capacity increases with minimal investment or lead time.

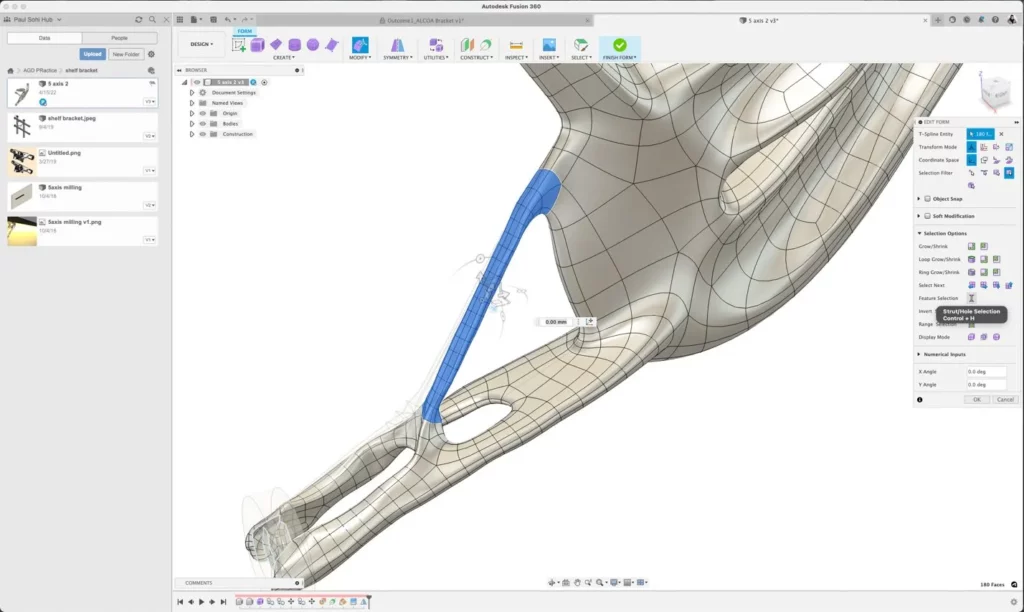

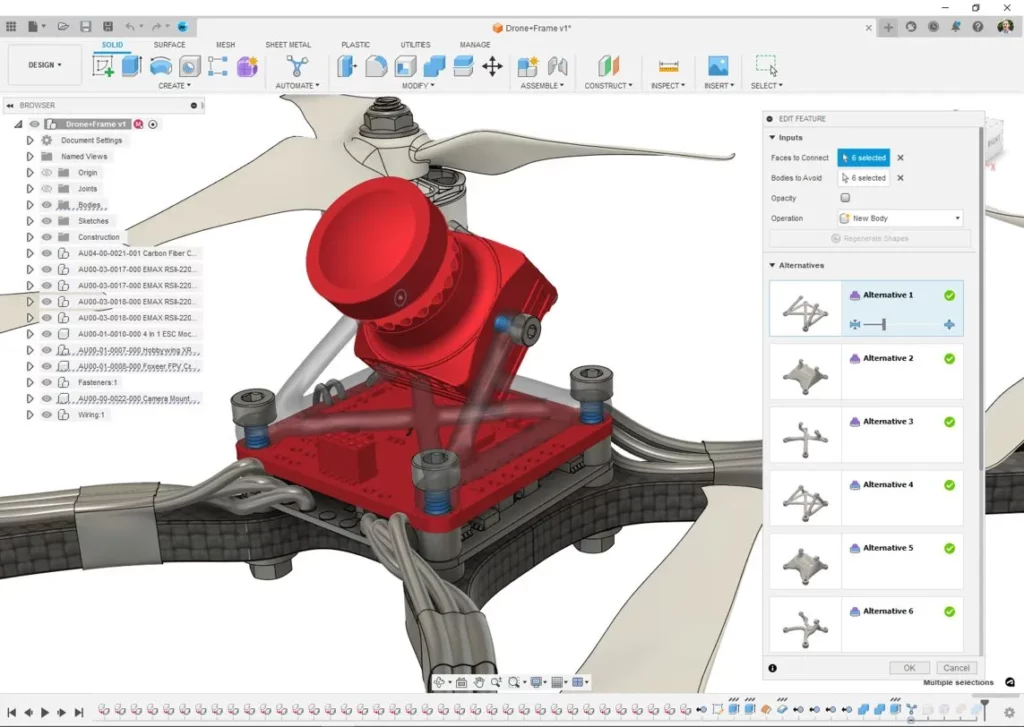

Yet another step: generative design and automated modeling

The latest advancement in the world of automated design is generative design and automated modeling in Fusion 360. Similar to rules-based automation, input variables and dependencies are built into the CAD model to capture customized requirements. This enhances the design phase with automated tools that iterate through many possible solutions, each one designed based on constraints defined by engineers (typically focused on performance, manufacturability, weight, and strength).

Humans are still important throughout this process, as they need to select an output, edit it if necessary, validate it and sign off on the final design. However, this effort is significantly less than the rule-based automation previously described. For example, generative design and automated modeling are especially useful to speed up the prototyping phase, as designers can sort through many ideas before pursuing the option that best suits their needs. Therefore, as these tools become more sophisticated and better trained, there is no question that this type of design automation will become a mainstay in the design process.

Grow smarter, work smarter with Autodesk Fusion 360

Whether using basic spreadsheet-style automation or the most advanced generative design tools, small companies can quickly gain an edge in scaling their business through automation. Automated design tools free up human resources to increase business capacity with minimal investment in time or capital. Autodesk Fusion 360 enables this type of growth by offering parametric design tools, automated modeling, and generative design. Learn more and begin growing your business with Autodesk Fusion 360 today.