Formnext 2022 starts tomorrow! And with it, the latest and greatest additive manufacturing news. Additive manufacturing capabilities in Fusion 360 have come a long way over the past year — especially when it comes to new features, performance improvements, and hardware integrations through our partnerships.

This year, we’re pleased to announce our new partnership with EOS to bring your additive manufacturing capabilities to the next level. EOS metal and polymer machines are already available in the Fusion 360 Machine Library, making print prep super easy. However, things are getting even better.

We’re very excited to join up with EOS to bring more additive functionality to Fusion 360 via state-of-the-art machine connectivity to EOS printers. Fusion 360 customers with the Additive Build Extension will be able to take full advantage of the new streamlined EOS machine workflows, including:

- Associative design and manufacturing to make the transition from design revisions to printing seamless.

- Comprehensive support generation tools and metal powder bed fusion process simulation capabilities to minimize potential build failures due to recoater jams or part warpage.

- Even those without the Additive Build Extension can still benefit —Fusion 360 has an integration of EOS polymer machines.

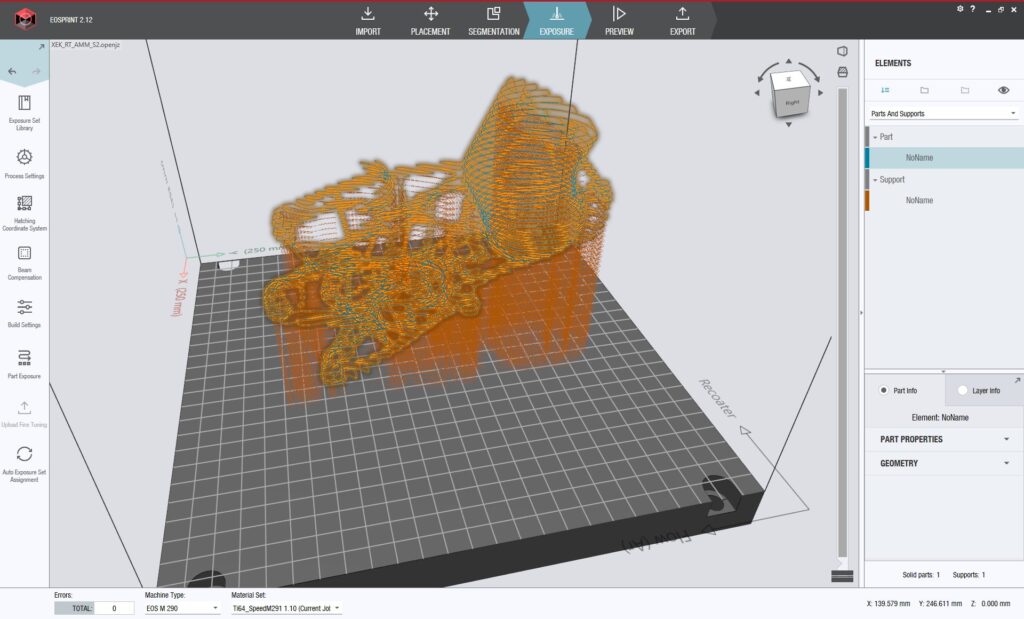

Today, with Fusion 360, you can orient your parts, create supports and simulate your build to create a compensated geometry to ensure part integrity when printing. Additionally, you can export your Fusion 360 build file to EOSPRINT 2 to preview your slices and stream your task to your EOS printer.

But there’s more coming! Want to get a teaser of what this partnership will mean for you? Keep your eyes on what’s happening at Formnext to learn more.

Want to learn more about the Fusion 360 Additive Build extension in the meantime? Check it out here. And, of course, download Fusion 360 today if you haven’t already: