This post is also available in: Français (French) Italiano (Italian) Deutsch (German) 日本語 (Japanese)

What is prototyping? Why is it necessary? How can you get started? Explore the answers to these questions and more.

Once you decide to design a new product, you must weigh the pros and cons of launching it in the market. You embark on the product development journey only after you think your new product will boost your business.

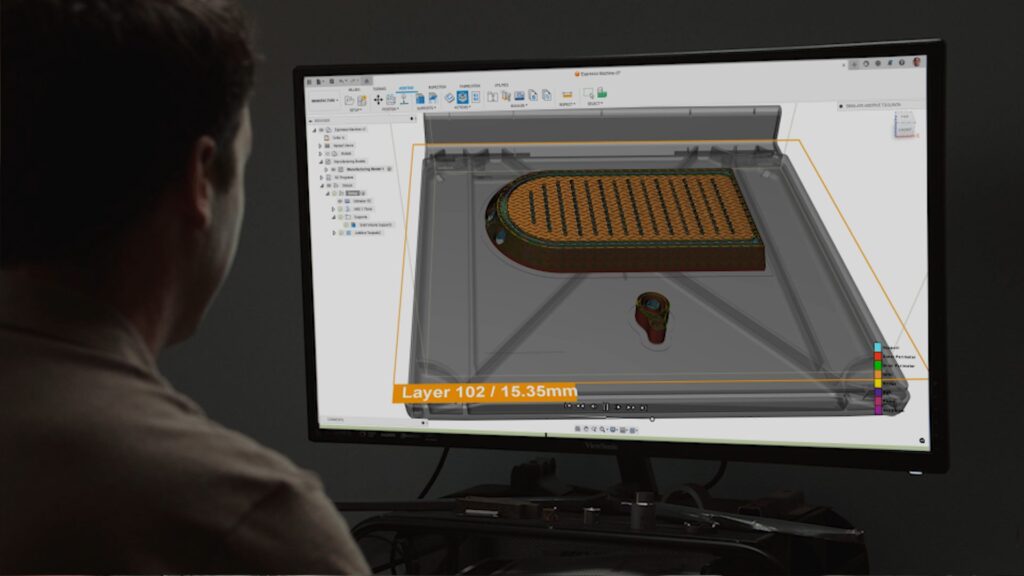

The first step in the product development process after 3D modeling a design is prototyping. Prototyping plays a vital role in deciding what your final product will look like and what changes you need to make to enhance your product’s performance. Let’s learn more about prototyping and how you can make your product development journey more efficient.

What is Prototyping?

Before a product developer moves forward with fabricating a final design, they make a sample of it called a prototype. A prototype can be anything from a PCB mockup to a 3D-printed version of a much larger product, depending on the product type.

In simple words, prototyping is creating an initial sample or a preliminary model of the final product. It allows the product developers to see how their final product will look and test its features.

Why is prototyping necessary?

Prototyping is imperative to eventually launching a successful product. It helps lower costs and saves product developers and designers from wasting their time and energy in unfruitful attempts to improve their products.

Prototyping helps developers build an initial design of their product, which they can use to test the functionality of their final design. For example, product developers can use a 3D printer to build their prototype and see how it works. Doing so would help uncover faults so they can work on correcting them.

Moreover, prototyping allows designers to build multiple preliminary models, each having different functionalities. They can build numerous prototypes, test them, and choose the one best suits their requirements. In this way, they can save the money they would have otherwise invested in making the final product and incorporating changes.

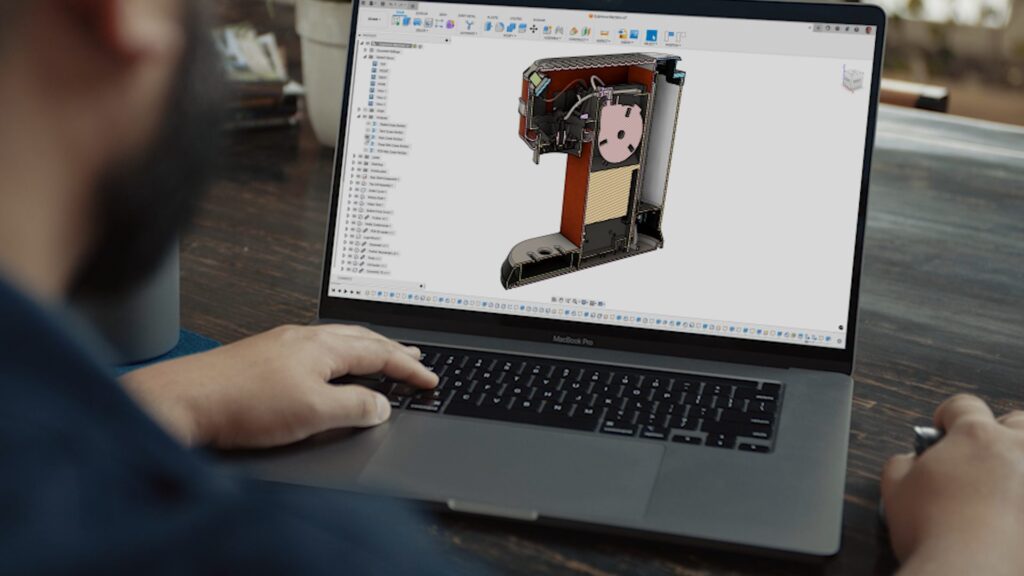

Besides saving themselves from spending thousands of dollars to improve their final product, product designers can use a prototype to turn their imagination into reality. A 3D model of their final product can help them propagate their vision better and save time they would otherwise spend explaining their final product.

This also helps product developers when reaching out to investors for funding or presenting early designs to clients and wider internal teams. They can use the 3D model of their final product to show what their product would look like and how it would work to get buy-in or approval to move forward.

As a product developer, you can also use a prototype to gain consumer insight. This will help you to gain valuable feedback early on and work to improve its design and functionality. It may also help you set a better market price for your product.

What are the best steps for prototyping?

Making a prototype can take anywhere from days to months. It depends on the design, detailing, prototyping method, and team size. You must have experienced people on your team who are familiar with creating prototypes for the process to go smoothly. Prototyping is never linear and requires people who can wear many hats. Ideally, they would have an understanding of 3D modeling, 3D printing, simulation, and so on.

First and foremost, you must fix a budget for product prototyping. By doing so, you won’t overspend when creating a sample of your final product. Having a budget in mind means you will use your resources carefully.

Everyone on your team must be familiar with the entire prototyping process. They should know the purpose of prototyping your product. Then, you must devise a plan of action for your team to ensure the whole process is streamlined.

You must include features in your product that match your customers’ preferences. Moreover, you must keep the consumer in mind while designing the prototype of your product. By keeping the end-users in mind, you will develop the perfect prototype that matches your customers’ needs.

Your team should know what resources and tools to use to ensure a smooth product prototyping process. They must work efficiently to save time they can later use to test and improve the product. The best prototypes are made by designers and engineers who try their prototype multiple times and redesign it until they get their desired results.

While testing your prototype, you can reach out to multiple people, including contractors, potential customers, investors, and other experts who might help improve your product. Through their feedback, you can make appropriate changes in your prototype and design a perfect final product.

Another helpful tip is to document every step of your prototyping journey. You must keep a record of your prototype at every stage. Record everything — the designs, improvements, feedback, performance indicators, etc. Doing so can save time in the future when you work on developing another prototype for a different product. And if you need to backtrack to a previous iteration, having a record on hand will eliminate stress.

What will the cost of my first prototype be?

Prototyping costs vary depending on the chosen prototyping method and material. You will save hundreds of dollars on your prototype using an economical method, such as 3D printing. The cost also depends on the functionality and complexity of your product. For example, a prototype might cost more if it’s a detailed design with multiple parts.

Even if you do select 3D printing to save costs, the chosen material will also affect the budget. For instance, some types of resin cost more than others because of their physical appearance and properties. If you are on a budget, you might want to choose a cheaper kind of resin for prototyping.

To improve your product’s functionality and design, you would create multiple refined copies of your prototype, adding to your overall cost. You must keep these additional costs in mind while creating your prototype.

To make things easy, consider prototyping as an investment. The amount of money you spend in the prototyping phase will help improve your final product. Eventually, it will help maximize your potential profit by confidently launching a validated product in the market.

The first step in the product development process is 3D modeling. To make prototyping even easier, it’s important to select a tool that has it all — CAD, CAM,CAE and PCB — so your team can collaborate throughout the entire process. See why Fusion is the ideal choice for design and engineering teams of all sizes: