This post is also available in: 日本語 (Japanese)

Check out how Japanese design studio Triple Bottom Line designed floating solar panels to protect nearby forested areas with the help of generative design software.

Thirty years ago, it was still out of the ordinary to see solar panels. But they are everywhere now — whether it’s on roofs, free-standing structures, in massive sports stadiums, or even on top of trash cans and parking meters.

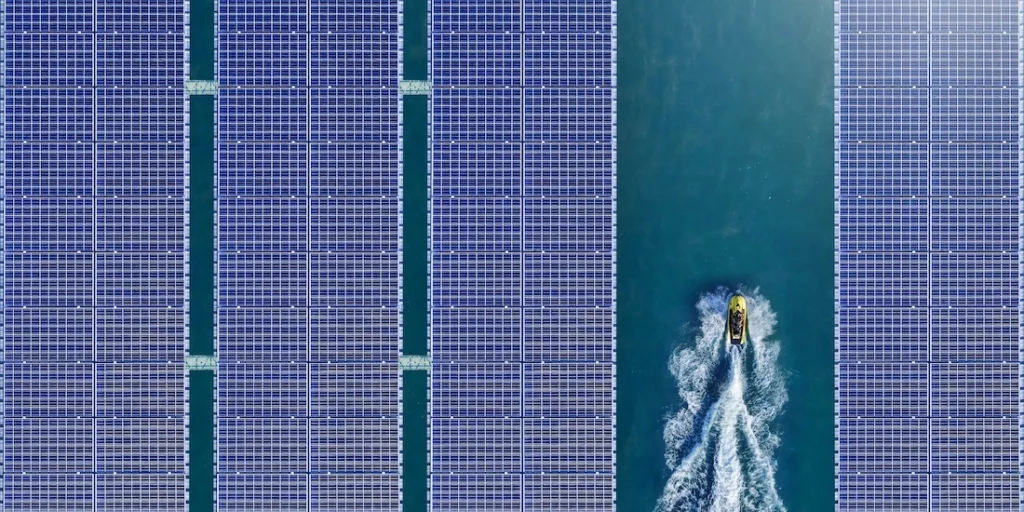

But what about using them on….water?

Floating photovoltaic systems are becoming an attractive alternative. Energy production is maximized with direct sunlight and the ability to track the sun. Water sources — such as reservoirs or other man-made bodies of water — can be used with minimal environmental impact. In fact, the cooling effect of the panels can help prevent evaporation.

Floating solar panels also provide an alternative to areas where solar can be difficult to install or are shaded. Japanese industrial designer Satoshi Yanagisawa of Triple Bottom Line notes these challenges in Japan.

“In Japan, making solar power systems on mountainsides and similar locations is becoming problematic because trees are being removed,” he says in a recent Redshift article. “Chopping down natural green resources to build something that’s supposed to benefit the environment is complete nonsense. We need to stop using land for power energy projects. Water is more reliable.”

Using generative design in Fusion 360 to find the ideal solar float

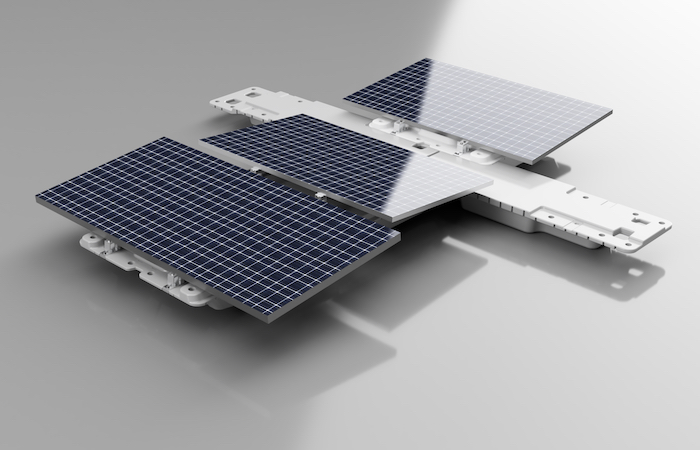

Yanagiswa was approached by a general contractor to design a float for a solar PV system. While many solar PV systems are standardized, the floats currently aren’t. With only a small team of five, Yanagisawa knew traditional design and testing methods would take too long to meet the 15-month deadline.

Using generative design in Fusion 360, Yanagiswa quickly discovered 500 float shape options based on the requirements for wall thickness and strength required. The team then narrowed it down to just a few and ultimately settled on a final design. With the final float completed in six months, he estimates it would have taken more than two years without generative design.

Learn more about Yanagiswa’s project and insights on Redshift. Ready to discover more outcomes with generative design in Fusion 360? Try the impactful tool for free today: