Elevate your design and manufacturing processes with Autodesk Fusion

Henlight develops solar powered lighting solutions for small scale farmers. They have developed a solar powered lighting unit that helps pasture raised poultry farmers increase egg production 15-25%, providing a more consistent supply of eggs to communities and grocers during the shorter days of the year, when egg production can drop 30-60%. In this post, Henlight Co-Founder Edward Silva talks about how his team was given the opportunity to serve small scale farmers by winning a global business competition seeking solutions to feed 9 billion people by 2050.

Why Henlight?

The past 2 years have been quite a whirlwind for me! Beyond starting a new job, getting married, and moving, I also co-founded a company whose sole focus is helping small scale farmers through appropriate technology. This last milestone is known as Henlight, LLC. I want to take a quick moment to share how we were able to make something out of an idea using the 3 key resources around us: the network, the farmer, and the shop.

Helping Farmers Do Well

In October 2013 our nascent Henlight team won $10,000 after pitching our idea in the International Thought for Food Summit global competition in Berlin, Germany. We were absolutely thrilled! Once back in California, a fear all too common to aspiring entrepreneurs receiving investment arose: what now? We knew our goal (help farmers do well), we had a clear idea about our market (small scale poultry farmers), and we had a solid understanding of the problem (less eggs during shorter days creates farmer/market hardships), but our team was comprised of non-engineers building a simple solution that involved complex systems. What now?

Within a week of our return, I reached out to a friend (Resource #1: The network) who I had worked with before, and whom I knew had engineering experience. He knew our story a bit and understood the technology we planned to build, and he joined our team. We spent the next few months building prototypes and talking to farmers. We spent very little money, learned a lot, and brought home a lot of chicken…stuff. It was a bit messy, as is any idea coming out to the market for the first time, but we were determined to keep moving forward. We began receiving very valuable feedback from farmers (Resource #2: proximity to farmers) that helped guide the eventual design, development, and scope of our Henlight solution.

Scrambled Eggs

On one hand, this was great: we were receiving valuable feedback from real-life farmers, had built a minimum viable product using a small amount of funds, and were quickly validating our market. On the other hand, every day of validation got us closer to having to face a very difficult question: how do we manufacture these Henlights effectively? After scrambling a bit, we came across our last key resource: the shop (Resource #3: the shop).

We connected with a self-taught engineer who not only had manufacturing experience, but experience in something called TechShop. Described to us as a public library for building almost anything, TechShop and all it had to offer was the avenue by which Henlight turned investment from Thought For Food i

Why Fusion 360?

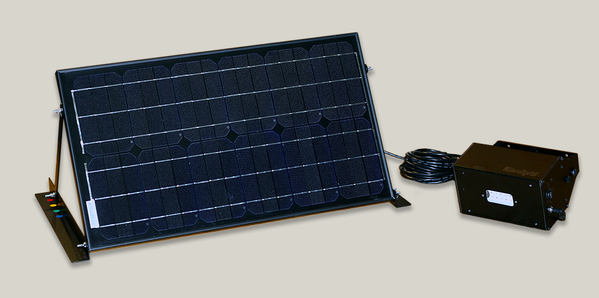

We used Fusion 360 to think about and actually act on the various designs we imagined. As a small start-up, we couldn’t afford to rebuild something multiple times. Having access to a tool that provides such unique and powerful insight – based on our different product iterations – allowed us to make the best choice (or so we hope!). We have used Fusion 360 to design the enclosure of our lighting system and the brackets for which to hold the light and the solar panel to their mountable surface. It’s so easy to use, and thankfully, since our team is not full of engineers, quick to learn! This has allowed multiple team members to participate in the design, or at least understand the conversation.

Fusion 360 allows small companies to do big things, and thus have an impact. That really is the core of moving an idea into reality, and we are thankful for such a great product to allow us that support.

To date we have since sold nearly 150 units to over 30 farmers and have seen positive results. We continue to appreciate and value our key resources, and with some more investment, hope to scale up to serve even more farmers.