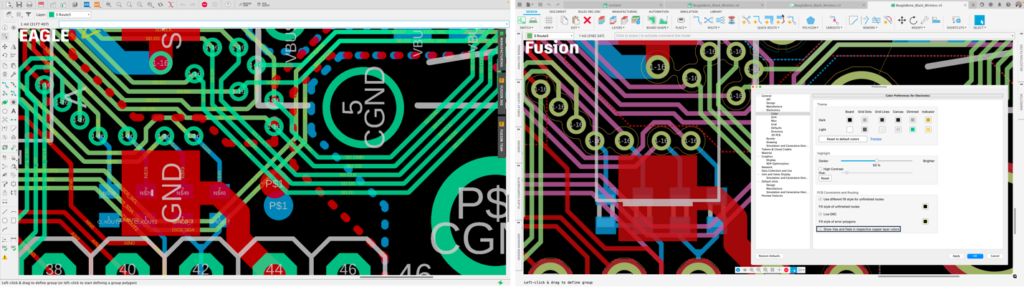

Here are 10 features you don’t want to miss as you migrate from Autodesk EAGLE to Autodesk Fusion 360.

It’s no mystery that at the core of Fusion 360 electronics, is a strong heartbeat of Autodesk EAGLE. The transition of EAGLE into Fusion 360 began shortly after its acquisition in the summer of 2016.

Our vision has always been to enhance the platform’s capabilities by seamlessly integrating PCB design into the broader product development ecosystem. By incorporating EAGLE’s PCB design tools into Fusion 360 electronics, Autodesk aims to give users like you a unified environment to seamlessly transition from concept to PCB layout with a more efficient product development process.

Let’s look at the top 10 features you need to know about when migrating to Fusion 360.

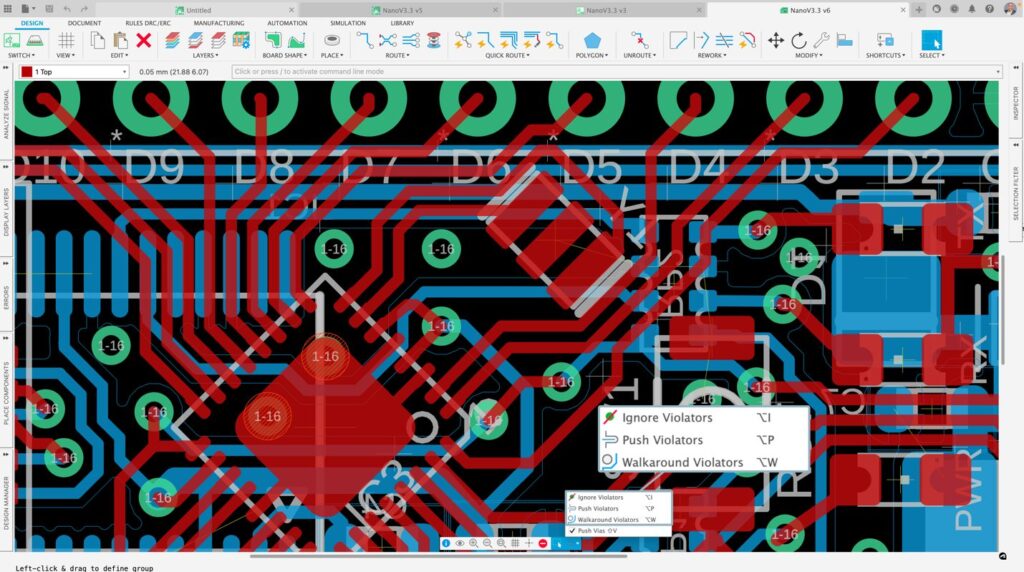

1. Obstacle avoidance, (aka violator mode): walkaround

One notable feature from EAGLE that seamlessly made its way into Fusion 360 electronics is the walkaround routing method. This manual routing feature leverages the power of live DRC (Design Rule Checking) to prevent the creation of shorts during component placement and signal routing. By intelligently considering the manufacturing settings defined in the design rules, the walkaround mode ensured that designers could route their PCBs while avoiding violations and maintaining the highest level of design integrity.

In the transition to Fusion 360 electronics, the walkaround mode underwent a slight transformation and became part of the broader family of the violator mode. However, the functionality and purpose remain the same, delivering the same powerful benefits as in EAGLE. The renamed walkaround violators continue to empower designers by enabling them to seamlessly navigate around existing components and routed traces, ensuring efficient routing and accurate component placement without compromising design constraints.

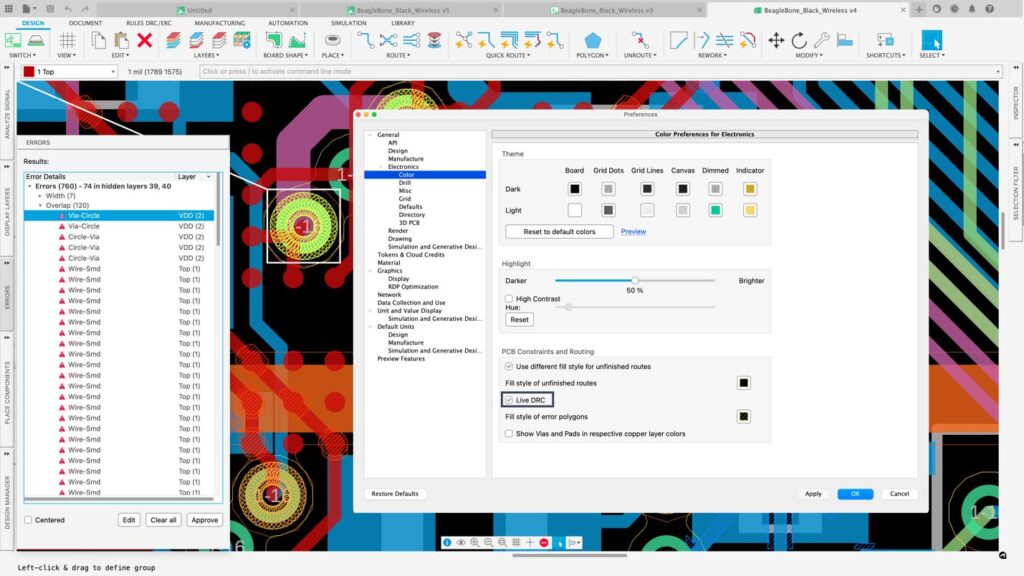

2. Live DRC (Design Rule Check)

Following the acquisition of EAGLE, our dedicated team of developers set out to enhance the design experience with a range of highly efficient tools. Among these advancements, one common challenge in PCB layout is ensuring a functional and manufacturable board. We decide to implement the live Design Rule Checker (DRC) in EAGLE. This remarkable feature dynamically alerts designers in real time if their design violates manufacturing preferences, providing instant feedback and marking the exact location of the offense.

This feature migrated to Fusion 360 electronics, where it synergizes with additional violator modes such as push and shove or ignore violators, further amplifying its usefulness. These powerful tools empower you to rectify violations promptly and fine-tune your designs for optimal design performance.

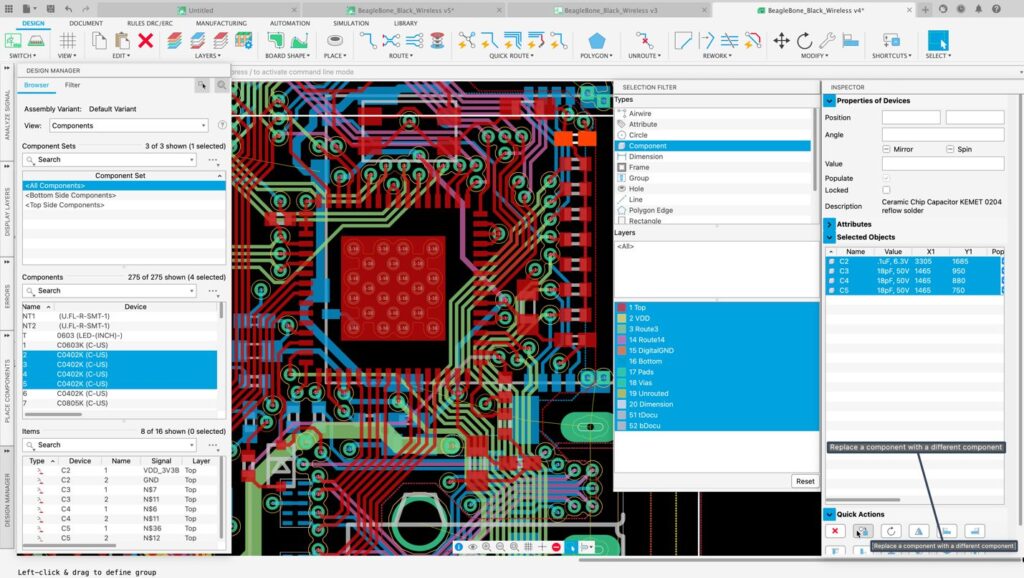

3. Edit multiple objects simultaneously through the object inspector

The object inspector feature in Autodesk EAGLE conveniently allows you to change selected assets within the PCB or Schematic editors. One of its most significant benefits is the ease of switching package types, such as transitioning from an 0402 package to an 0805 style.

Traditionally this was nearly impossible with EAGLE. However, with the implementation of the design manager combined with the object inspector, designers can select the desired assets on the PCB and access a wide range of options in the inspector panel. These options include changing the package type, modifying the value, adjusting rotation, and various other properties.

The good news is that EAGLE’s powerful object inspector tool has transitioned into Fusion 360, retaining its functionality and capabilities. This tool continues to be an asset in the design process; another example is selecting a group of traces and efficiently modifying their properties, including wire width and other attributes.

By adopting this feature from EAGLE and adding the selection filter, Fusion 360 electronics provides a better design experience that will accelerate project timelines.

4. Automatic board outline detection

Autodesk EAGLE detects the PCB outline as part of its Design Rule Check. Initially, this detection was limited to flagging violations on a specific layer. However, it evolved into a smarter functionality, integrated within the EAGLE PCB workspace. Notably, the workspace canvas background color distinctly differentiates the PCB area.

Moreover, the Cam Processor in EAGLE gained enhanced capabilities, enabling it to identify board shapes and cutouts. This instrumental implementation simplifies the process of detecting and defining the PCB outline. It made its way into Fusion 360, ensuring continuity and enhanced efficiency for designers migrating to Fusion 360.

5. Draw vias in respective layer color

In response to user feedback, the Autodesk EAGLE development team introduced a feature that allows users to see the shapes of vias and pads on their respective layers. By matching the color of the pad and via to the background, EAGLE dynamically displays the pad and via with the color and shape associated with their respective layers. This implementation proved to be highly effective, enhancing the visibility and clarity of the design.

When integrating EAGLE into Fusion 360, the XD (Experience Design) team recognized the value of this functionality and decided to make it even more accessible. As a result, they included an option within the Fusion 360 electronics workspace preferences, allowing users to quickly review the shapes and sizes of vias and pads on each layer, providing enhanced visibility and control during the design process.

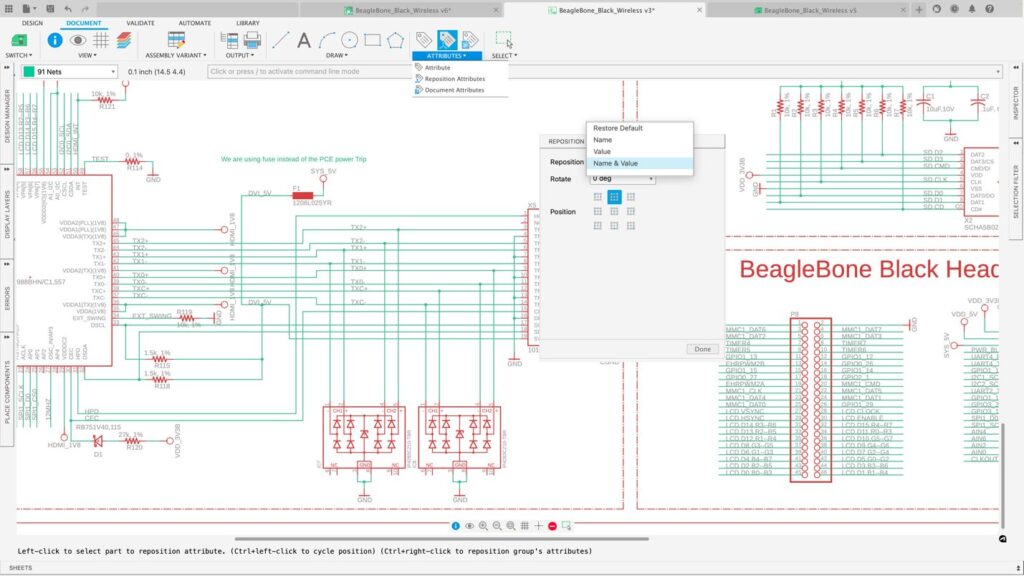

6. Reposition attributes

Component placement on a PCB or schematic involves more than just the positioning and rotation of electronic parts. It also requires careful consideration of factors such as readability and design documentation. Key elements are the Name and Value attributes of components. Their placement and alignment are crucial for effective readability, ensuring that critical information, such as the value of a capacitor, can be easily understood without additional effort.

To address this challenge, Autodesk EAGLE introduced the Attribute Reposition command. You no longer had to adjust and align labels based on visual estimation manually.

This improvement didn’t stop at EAGLE; it was also incorporated into Fusion 360 electronics. With the Attribute Position command in Fusion 360 electronics, designers can access a panel that offers eight position options and label rotation. This integration simplifies documenting the design, ensuring it is well-documented for manufacturing or troubleshooting purposes.

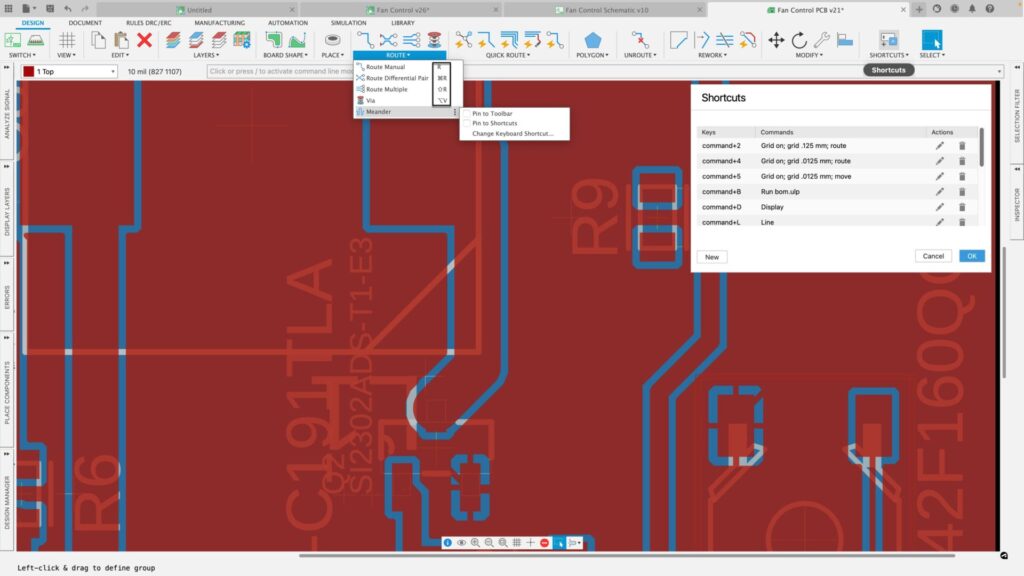

7. Keyboard shortcuts

In the world of CAD applications, keyboard shortcuts play a crucial role in enhancing the design process’s efficiency. Fusion 360, in particular, offers quick access to commands and task execution, reducing the reliance on extensive menu navigation. The software provides numerous pre-set shortcuts for common commands and allows easy configuration of custom shortcuts.

Furthermore, Fusion 360 goes beyond by introducing a feature that enables users to create personalized command strings and associate them with specific keys. This proves highly advantageous as it allows shortcut customization for frequently used script files or ULP’s.

8. Command line

The command line in Autodesk EAGLE is a powerful tool that can conveniently execute specific commands, command strings, or script files by typing the command. The command line allows you to access EAGLE’s features without searching for them in the GUI.

By typing the appropriate command and parameters, you can access specific functions directly, which can be especially helpful for advanced users already familiar with the software. The good news is that The Fusion 360 electronics workspace has retained its invaluable legacy feature and is in the same spot as in EAGLE.

9. Polygon copper pouring

Leveraging polygon copper pours on circuit boards is integral for optimizing grounding and power distribution, mitigating electromagnetic interference (EMI), and bolstering signal fidelity. Although EAGLE’s polygon pouring functionality was proficient, it necessitated manual intervention. Fusion 360, on the other hand, has substantially enhanced this process, making it more user-friendly and performance-efficient, while providing more intelligent manufacturing outputs.

Unlike EAGLE, where alterations to polygon geometry necessitated manual calculation invocation, Fusion 360 eliminates this need. Any modifications to the PCB automatically instigate a polygon recalculation, providing improved visualization of the final pour results. Uniquely, Fusion 360 allows the polygon copper pour visualization to be deactivated while maintaining a ghosted polygon representation.

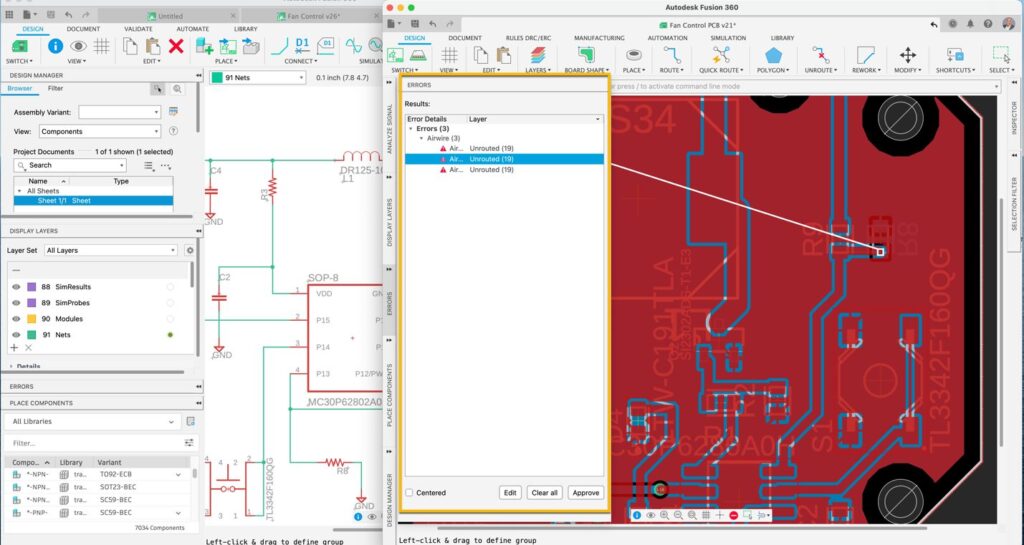

10. Error panels

During the circuit design phase, it is prudent to meticulously inspect your schematic and PCB for potential errors. EAGLE provides a modal error dialog that constrains the review of errors and warnings. Fusion 360 has enhanced the process by adopting the Electrical Rule Check (ERC) and Design Rule Checks (DRC), proven tools for potentially conserving resources by alerting you of issues during the design phase.

Incorporating persistent panels allows for continuous error monitoring, eliminating the need for post-process tasks. Furthermore, the Live DRC in the PCB editor provides real-time updates on manufacturing discrepancies or warnings, facilitating an efficient design process.

Take a look a the following video to see these features in action:

Product development made easier

Product design is evolving at an unprecedented speed, with products becoming increasingly intelligent and sophisticated. As designers, engineers, and innovators, we must harness the tools to meet the escalating pace of bringing products to market.

Fusion 360’s design platform offers a distinctive design experience that provides collaboration and efficiency. With advanced features and intuitive interfaces, Fusion 360 empowers you to navigate the complex landscape of modern product development and deliver superior outcomes in a timely manner.