This post is also available in: 日本語 (Japanese)

Fujifilm Engineering Co., Ltd. provides design and maintenance solutions for its customers based on the advanced engineering technology it has developed over its extensive history in film production equipment. To achieve its long-term stable production of high-quality products, the company has consistently focused on improving its overall production process planning, equipment design, and maintenance technology.

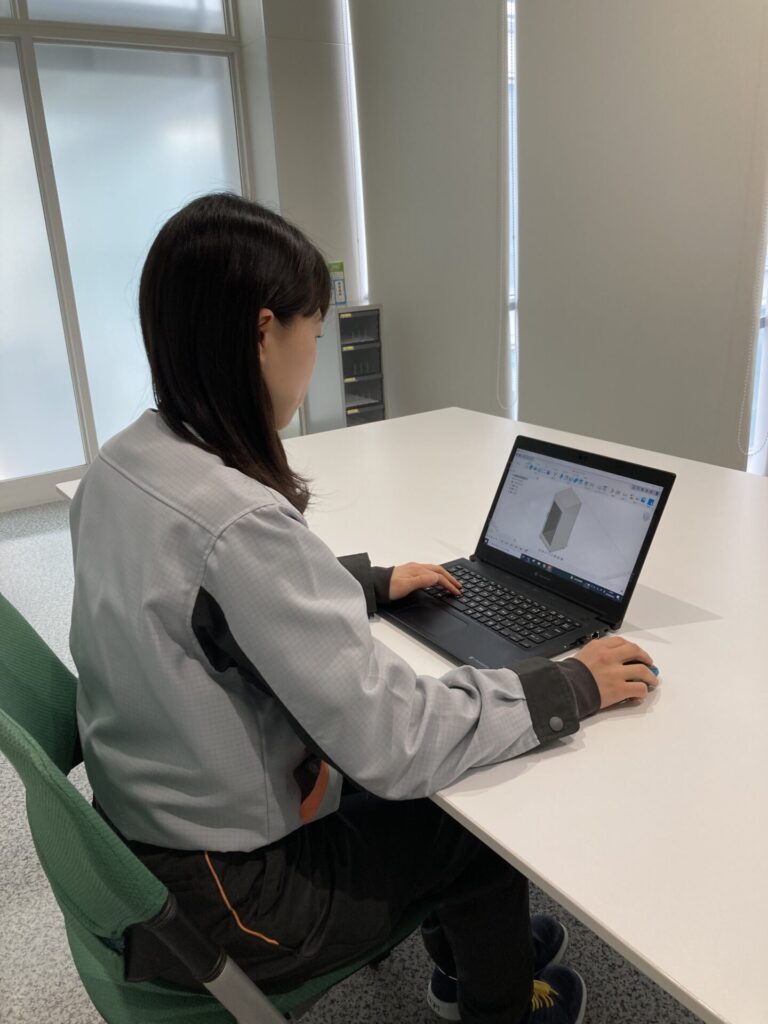

In 2020, the company’s Engineering Division introduced Autodesk Fusion to improve the efficiency and accuracy of its design work. The department is currently conducting in-house Fusion training for new employees as part of its efforts to widely disseminate use of the tool within the company.

Using Autodesk Fusion to deliver customer-centric solutions

Beyond design quality, Fujifilm Engineering also values communication with customers to ensure they’re provided with an optimal solution. “We always aim to improve the value of the solutions we provide,” says Yoshio Takechi, manager, Fujifilm Engineering. “We evaluate solutions based on quality, cost, and delivery from the customer’s perspective.”

“We are promoting 3D design throughout the company, and as part of that, we are providing CAD training to new employees using Autodesk Fusion.”

—Yoshio Takechi, Manager, Engineering Division, FujifilmEngineering Co., Ltd.

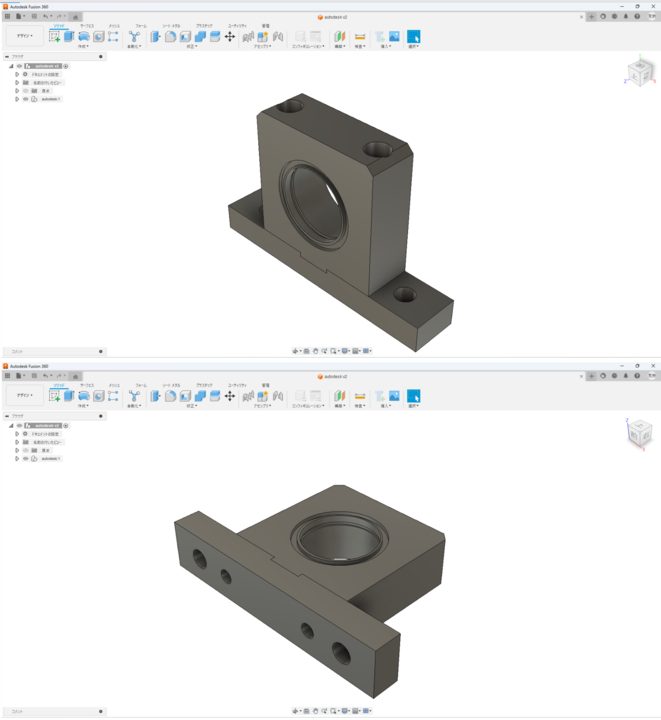

“We do not simply execute requests from customers, but rather proactively make suggestions as we work, so communication is extremely important,” adds Mitsunori Fujita, manager, Fujifilm Engineering. “When making a proposal, we show the 3D model designed using Autodesk Fusion, which makes it easier for the customer to understand the design, so the work proceeds smoothly.”

Unlocking significant time and cost savings

The Fujifilm Engineering team noticed a clear benefit of adopting Fusion when it came to checking for interference between parts. “When we were designing with 2D drawings, checking for interference between parts was a time-consuming and labor-intensive process – it used to take more than a day,” recalls Kenken Jo, designer, Fujifilm Engineering. “By using Fusion’s interference checking function, the time required for interference checking was reduced to less than half a day. It made the process so much easier.”

“Our goal is for more than 80% of our designers to be able to use Autodesk Fusion within three years.”

—Yoshio Takechi

Both customers and internal teams have taken notice of the Fujifilm Engineering team’s CAD use and are even finding benefits of their own. As a result, the team plans to continue, and even expand, its Fusion use. “Recently, our 3D design efforts have been recognized,” says Takechi. “We have had more instances of customers and internal stakeholders asking us to send them 3D models so that they can create reporting documents.”

Looking toward the future: Integrated CAD and CAM

As part of its intentions to expand Fusion use, the Fujifilm Engineering team is considering adopting the tool’s CAM features. “Autodesk Fusion also comes with CAM functions,” says Jo. “Once you become proficient with them, you can seamlessly carry out design and processing, allowing you to work more efficiently.”

“In addition to CAD, we would like to use CAM to improve the processing efficiency of core equipment that cannot be sent outside the company, and CAE to prevent design setbacks due to insufficient strength, resonance, etc.,” Fujita expands.

Thankfully, Autodesk Fusion offers a wide variety of free learning content to help teams like Fujifilm Engineering up-level. “Fusion has a wealth of educational content, such as YouTube tutorials,” Jo continues. “It’s relatively easy to learn how to use Fusion, so I would like to continue mastering its various functions.”