“One of the things 2020 has taught us is that we are more resilient then we’ve ever believed.”

– CEO Andrew Anagnost

2020 showed us just how much good we can create when we come together and use the technologies available to us. It also showed us how connected we are and that the nature of work has evolved. More and more of us have adapted to ways of working remotely and with teams around the world. Our commitment to your success remained unwavering as we helped each other overcome challenges that we were all dealing with.

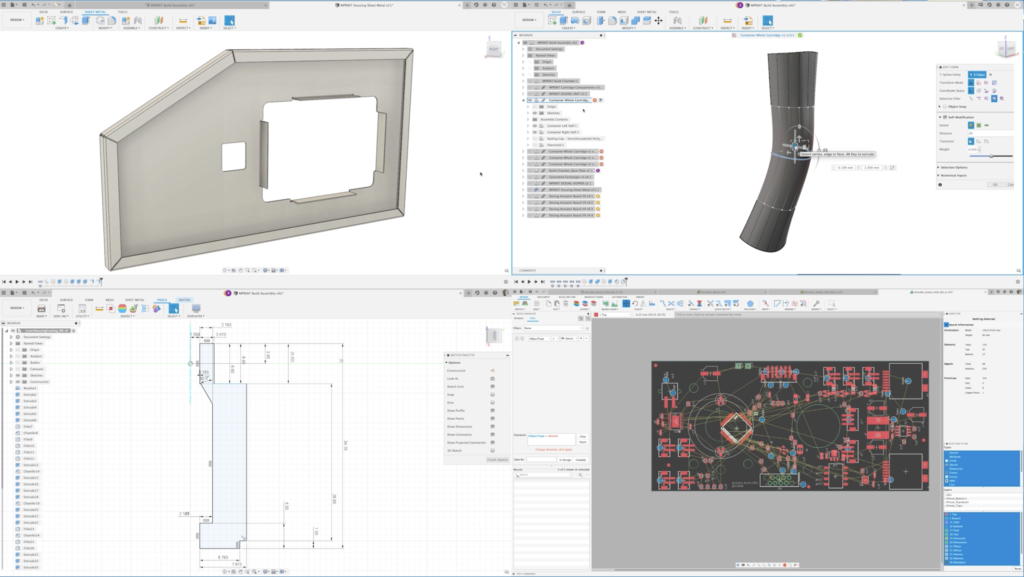

Without skipping a beat, we delivered a total of 35 product updates in 2020. These updates included brand new workspaces, powerful new functionality, and tons of feature improvements, all of which contribute towards the 3 major areas of focus we’ve been working towards:

- Maturing Design & Engineering

- Pushing what’s possible in Manufacturing

- Strengthening Data Management

We move so fast that it’s always good to slow down and look at what we accomplished last year. Here’s a quick look at 2020, the year in review. We can’t wait to show you what we have cooking for 2021.

2020 Year in Review

Timeline

Here’s a recap of new capabilities now available to you in Fusion 360:

| Design & Engineering | Drawings | Manufacturing | Data Management |

| 3D sketch, Text-on-path | Sketch tools | In-process Stock | Fusion Team file sharing control |

| Edit-in-Place | Line weight control | Manual Inspection | Design history from browser tree |

| Parting Line Draft | Section View Depth control | Arrange | Design Milestones |

| Rule Surface | All-level parts list | Manufacturing Model | |

| Emboss | Hole & Thread notes | Slice/Generate gcode for FDM | |

| Electronics Design | Welding Symbols | Nesting Preview | |

| Generative Design Extension | Better Title-block editing | Manufacturing Extension | |

| 2 Axis & Additive Constraints | Performance and usability | Additive Build Extension |

These numbers show how much we’ve grown together:

What we’re working on

We’ve got a lot of great projects cooking for the year, and we can’t wait to get them into your hands. Continuing where we left off in 2020, we are focused on delivering functionality and experiences that contribute towards the three major pillars mentioned above. Here’s are some key projects we are working on.

| Design & Engineering |

Sketching & Modeling Maturity

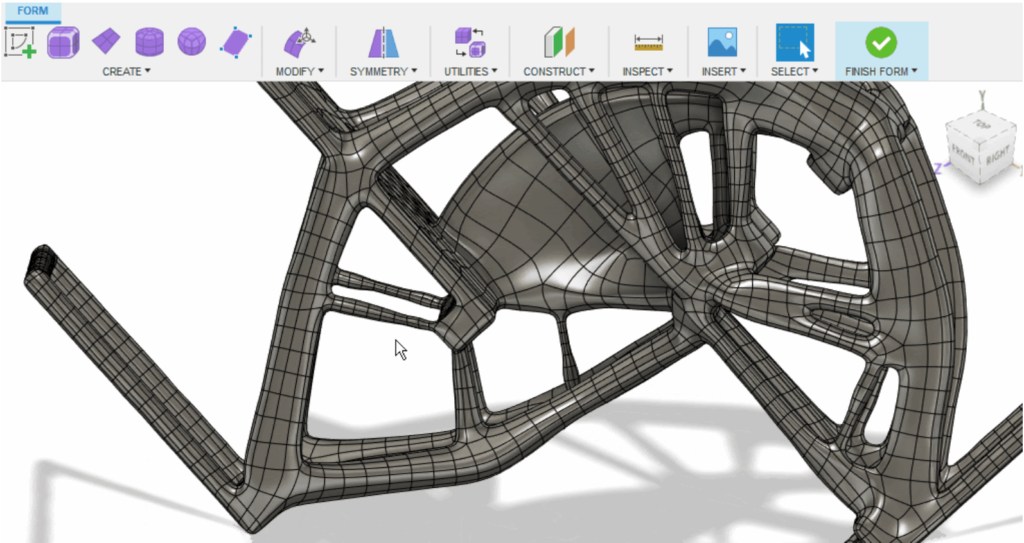

Based on your feedback and directly contributing to one of our major themes, we are continuing our efforts to add depth of capabilities to our sketching and modeling tools, expected for professional use by you. We are working on advanced sketch features like equation curve, parametric T-Splines, Thin Extrude, Tangent Joints, and a major overhaul of the Parameters user experience.

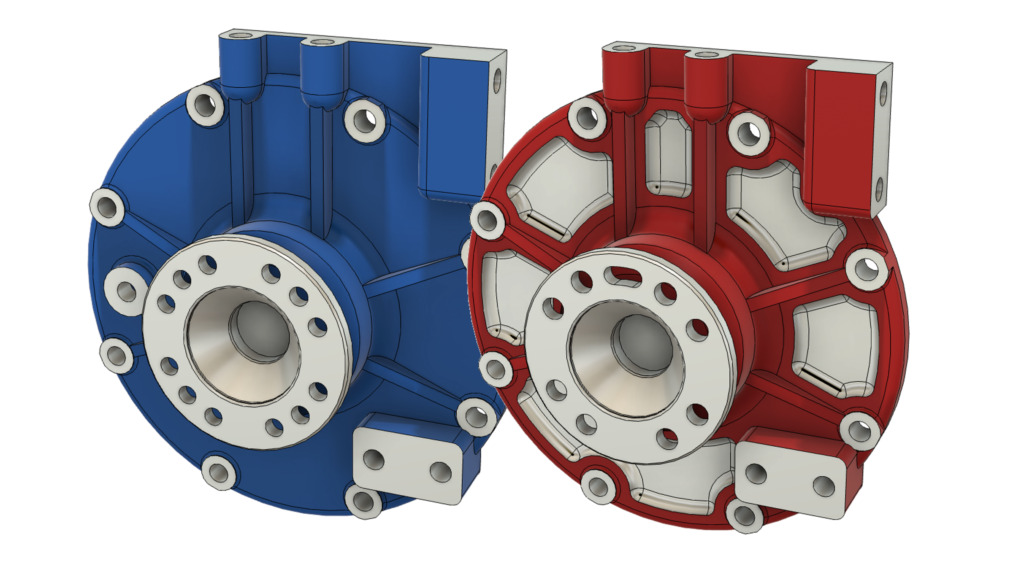

Part & Assembly Configurations

Your customers’ needs are unique, and each one has their own preferences and requirements. Our Part & Assembly Configurations project is a Multi-discipline solution that will enable you to produce part and assembly design variants so that you can fulfill custom requirements faster. And since this is Fusion 360, this also means that the variants can also include manufacturing, simulation, drawing & rendering configurations.

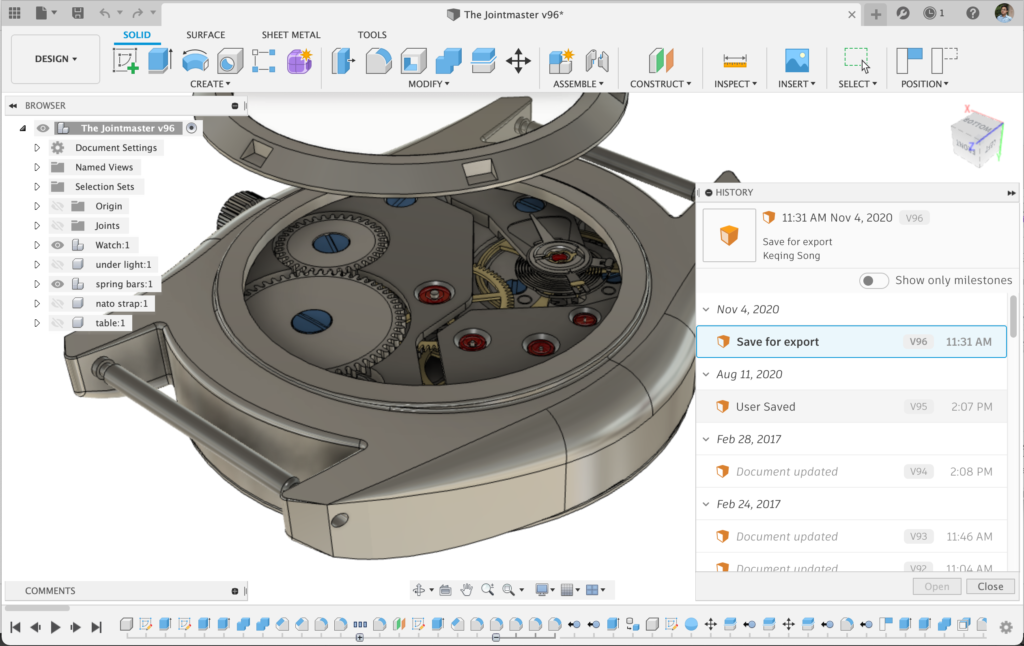

Assembly Concurrency

Wouldn’t it be great if you and your team can simultaneously work on a design and see who is working on what in real-time? We thought so too, but unlike word processors and spreadsheets, pulling this off for CAD is a slightly more complicated task. That’s where Assembly Concurrency comes in. We’ve been working on this project by laying down the foundation (Derive, Edit-in-Place, Assembly Contexts, Create External) and are now starting to work on introducing an experience that will help teams reduce conflicts often seen where multiple contributors are accessing the same distributed design. This will include things like real-time badging of who’s working on what, more flexibility around handling components in an assembly, as well as resolving broken references.

Synchronizer in Electronics

When you place a symbol in the 2D schematic of your Electronics Design, you automatically get the physical component’s pattern (A.K.A. footprint) for the Printed Circuit Board (PCB). Changes made in schematic automatically propagate to the PCB and vice-versa to an extent. However, these changes may not always be desirable. Given the complexity of electronics, we often wish to re-use elements we’ve already spent time perfecting before. We want to store sub-circuit elements in their own schematic documents and merge them later into different designs as reusable elements. When changes are not synced, we spend way too much time jumping through re-design hoops to get everything back to a matched state between schematic and PCB editors.

To solve this, we’ve been working on a new “Synchronizer” that allows different design elements to be better synchronized from schematic to PCB, PCB to schematic. This new Synchronizer will be a powerful addition to the Fusion 360 Electronics design workspace that is delightful to use and intuitive to control the flow of data between schematic and PCB (and even other document types in the future), enabling collaborative workflows and design re-use better than any other ECAD that we know of.

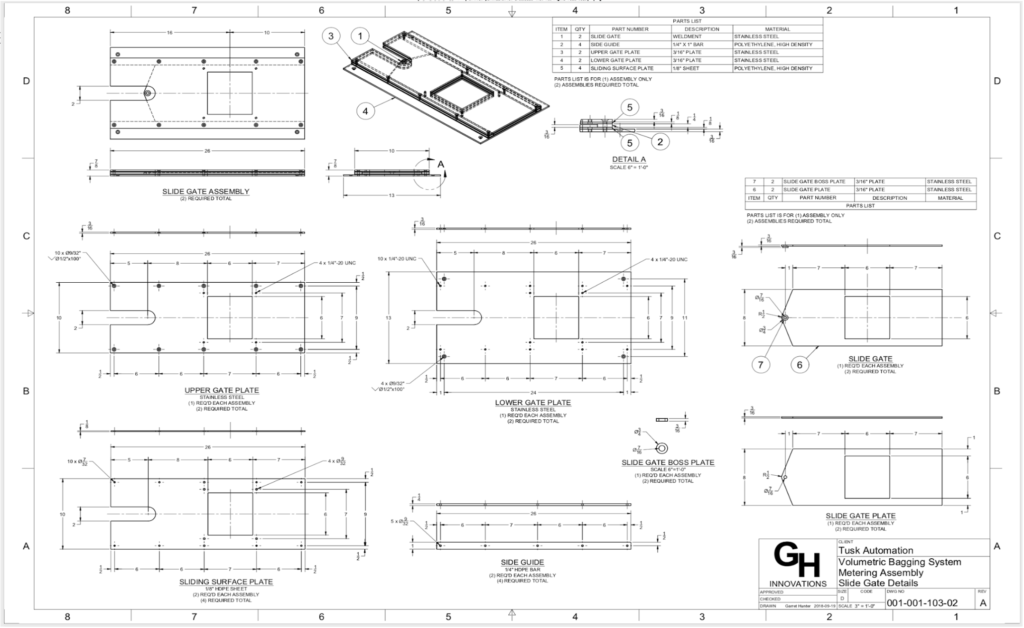

Drawing Maturity & Automation

Drawings are still a vital step in the manufacturing process. With the momentum you’ve seen from last year, we are continuing our efforts to mature the toolset and deliver what we’ve laid out on our drawings roadmap and introduce broken views as and extending standards support for JIS and DIN. We’re also working on expanding the automation and machine learning of drawing views and annotation capabilities through what we’ve done with Smart Templates.

Mesh Out-of-Preview

Many of you have told us that the Mesh environment needs work, and we totally agree. Several limitations to the Mesh tools today prevent you from leveraging all that Fusion 360 has to offer. This year, we’re going to change that — we’ve been working on making it parametric and more powerful. It’ll retain the tools it already has — creating, preparing, and modifying mesh bodies — but it will also enable you to make better use of them and convert them into more usable geometry. Stay tuned for more details as we learn more about our progress.

| Manufacturing |

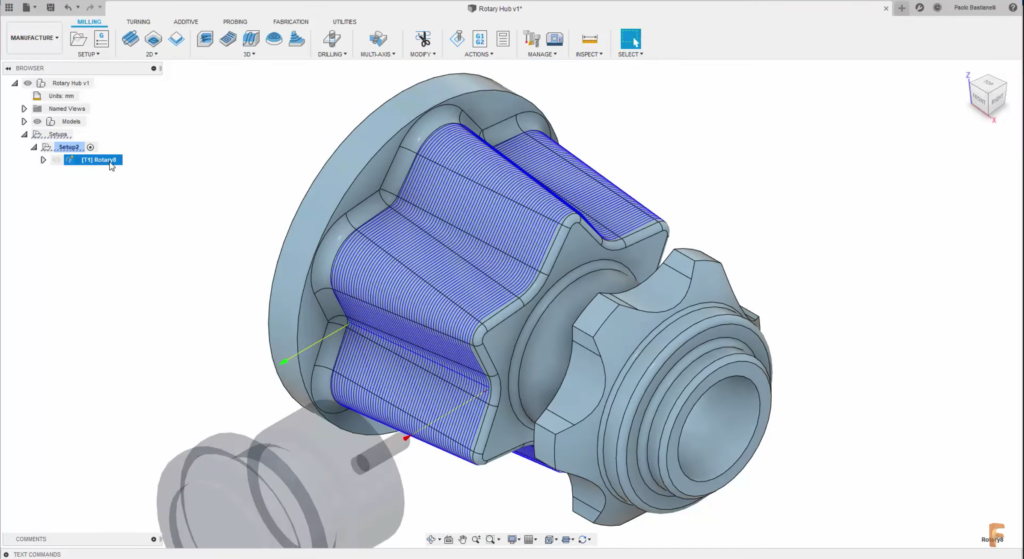

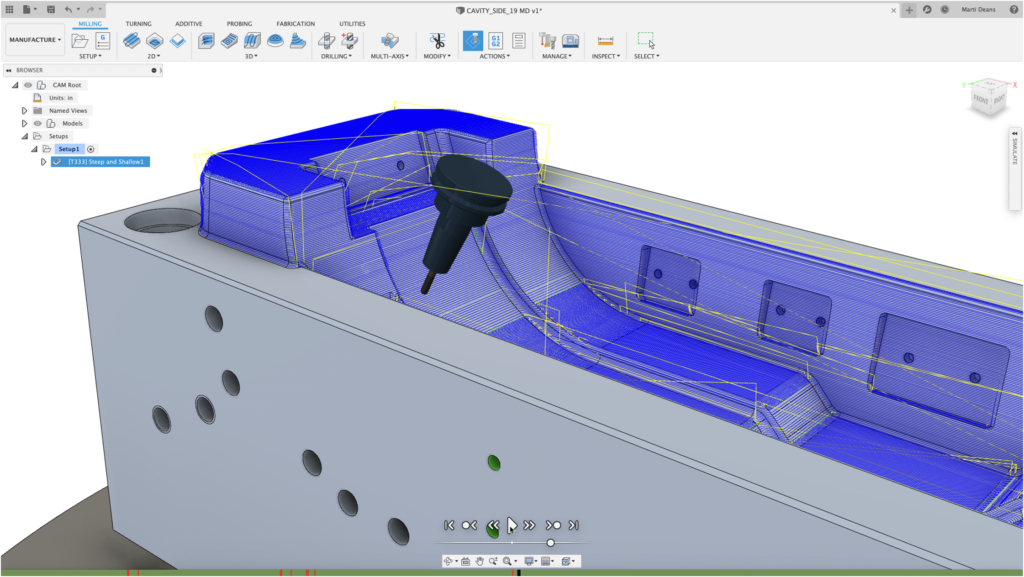

Strategies and Toolpaths

With all the functionality now available in the Manufacturing workspace of Fusion 360, we continue to refine the experience, consolidate new technologies, improve quality of life, and push what is technically possible. We’re working on a Rest Strategy that is designed to identify, and machine residual stock left by previous finishing toolpaths. This toolpath strategy is designed cut steep and shallow regions individually in an optimized manner. A second new strategy is designed to identify and cut all the flat regions on a model. It will automatically identify open pockets and therefore, enable the tool to approach from the open sides.

We’re also working on enhancements to the Steep and shallow strategy that will allow you to avoid Flat regions is being added as well as an option to identify and cut undercuts in the steep regions is being added.We are working improvements around tool orientation so you can set your tools from a point at non-planar surfaces, use graphical handles to better support Tilt and Turn as well as align to the surface Normal.

Along those lines, you’ll also see efforts around improving the efficiency of the 3D Adaptive and Pocket toolpaths when undercuts are present in the stock, resulting in reduced air cutting. This can significantly reduce the machining time. We are also working on adding most of the multi-axis technology currently available in the Steep and Shallow strategy, to most of the other 3D finishing strategies. This should provide much more flexibility for 5 axis machinists.

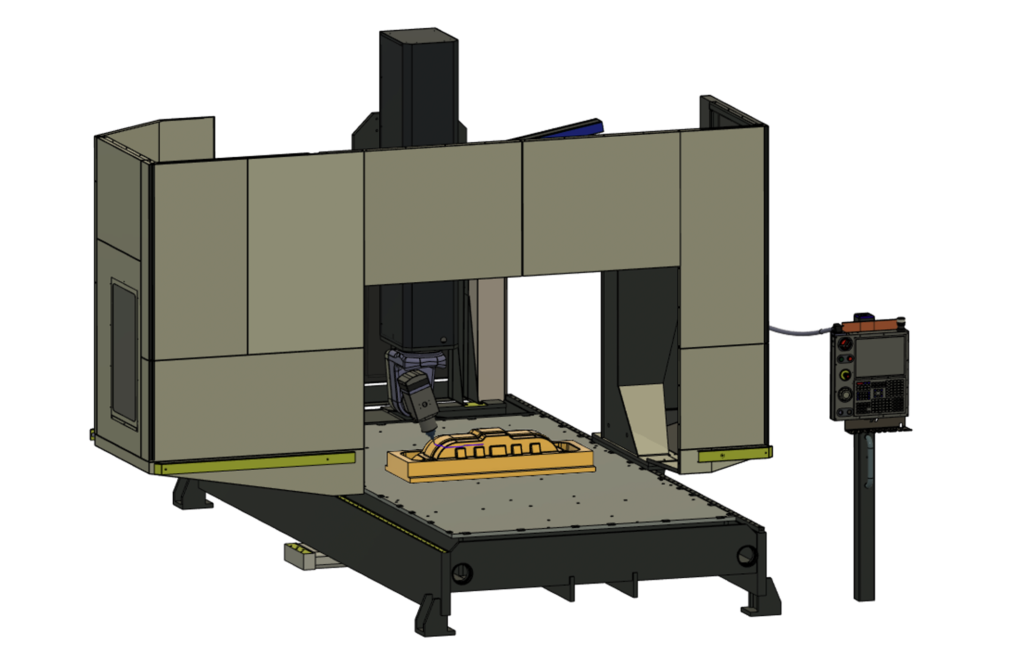

Machine Simulation

As we continue to make advancements in the manufacturing capabilities of Fusion 360, we’re also working on more advanced simulation functionality, which will give you more confidence in running collision-free programs. One of the most popular simulation methods is ‘machine simulation,’ which will give you the ability to load your machine tool model directly in Fusion 360 and virtually simulate the machine movements (in context to the entire CNC machine and not just the tool-bit/material stock), before sending the code to the machine and making the cuts in real life. The post processor drives the simulation to ensure the results you see on screen are what you will get on the machine tool.

Manufacturing Platform

Consistency. That’s the overall theme that encompasses our efforts around improving the manufacturing platform. Today, the post processing experience feels different on macOS and Windows machines. How you set up NC programs and post properties should be parametric, and consistent across all your devices, regardless of operating system. Another area of improvement we’re focusing on is streamlining the selections behavior across the different toolpath strategies. We want it to feel more natural, and more intuitive, so that going from modeling to machining in Fusion 360 is as smooth as it has ever been.

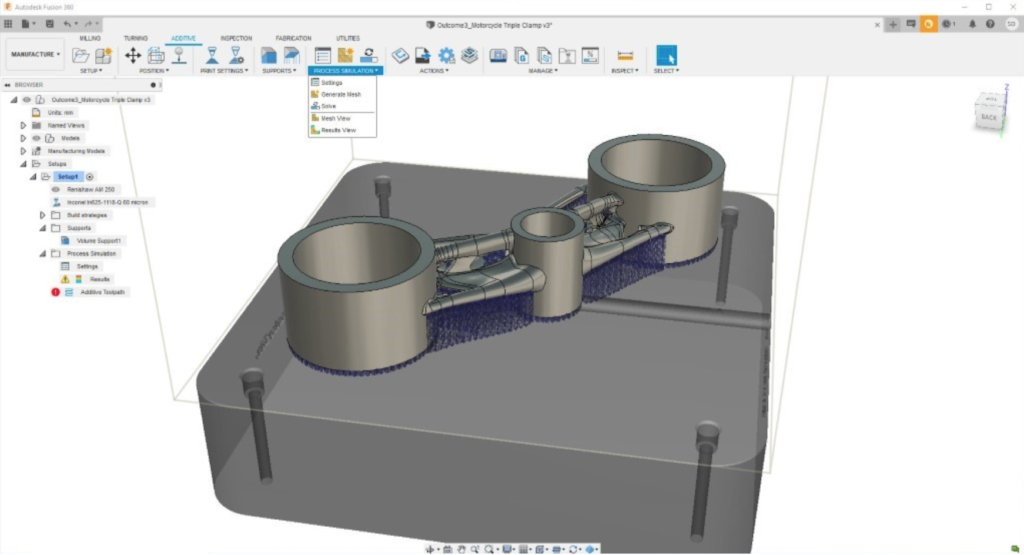

Additive

Last year, we made big strides in additive manufacturing by adding new functionality in Fused Filament Fabrication workflows, introducing the Additive Build Extension, and adding support for 50 FFF machines. We are now working on expanding on our Extensions capabilities with an Additive Simulation Extension where you will be able to replicate real-world additive manufacturing processes before printing in real-life. We will continue to add support for more machines, developing a Machine Connectivity App that will enable more extensibility.

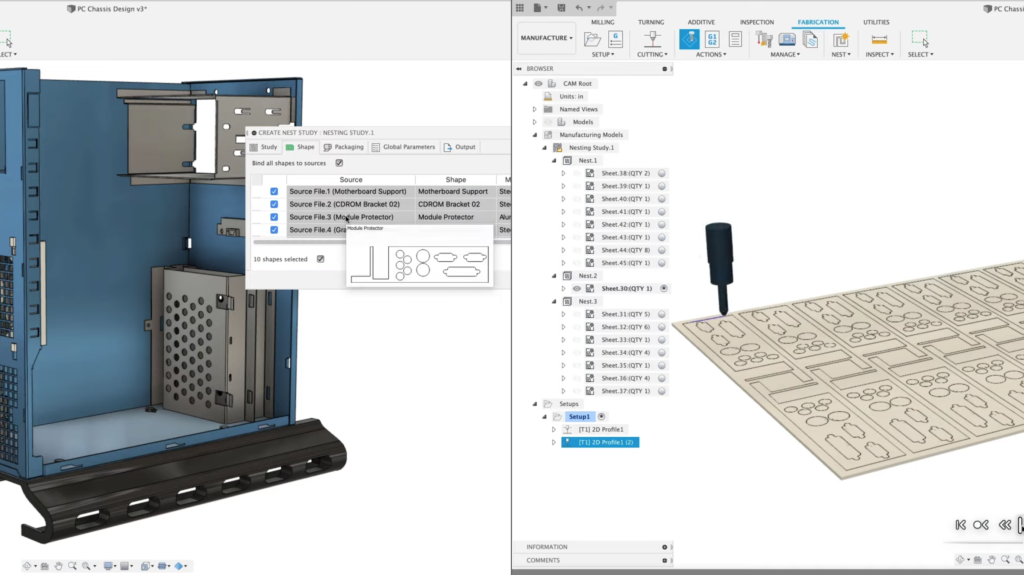

Nesting Out-of-preview

With Nesting currently available to try as preview functionality (as of the Manufacture Extension), we want to hear from you and get it ready to make it available for prime time, in production for professional use. Nesting includes integrated, automated, and associative nesting capabilities to optimize flat parts’ arrangement, both sheet metal and non-sheet metal, on flat raw material in preparation for cutting operations. It allows you to generate nests from your Fusion 360 designs and create toolpaths and NC code to drive your CNC machines – end-to-end seamless workflow all within Fusion 360. With model changes, related nests become “out-of-sync” and can be updated associatively.

| Collaboration & Data Management |

Though we didn’t implement many collaboration and data management features in 2020, we’ve been working hard at laying the foundation of what’s to come this year. Shayne Prichard (Product Manager) talked about this work in our roadmap webinar last year, and here’s an update on where we are at.

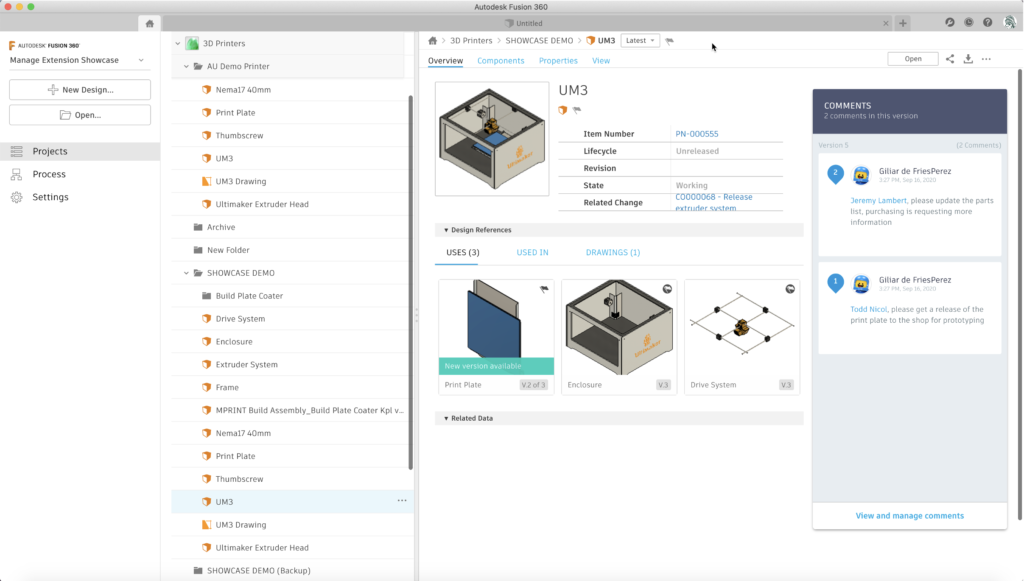

Manage Extension

Data is at the center of your product development lifecycle, and we’re bringing a more integrated change management experience to Fusion 360. The Manage Extension will enable you to assign numbers, release and manage change for your designs right within the Fusion 360 UI. It also allows stakeholders (or non-Fusion 360 users) to participate in the workflow, weighing in on the release process as reviewers/approvers, consume release data like never before.

Unified Data Experience (home tab)

In terms of accessing and managing your data, the data panel feels very different from Fusion Team on the web browser. We need to unify the experience so that it feels consistent and not disconnected. This project will introduce a new home tab where you can access and manage everything related to your data, including all of their version histories, associative assets, comments, and properties. With Assembly Concurrency in place, you’ll also be able to see who on your team is working on which design.

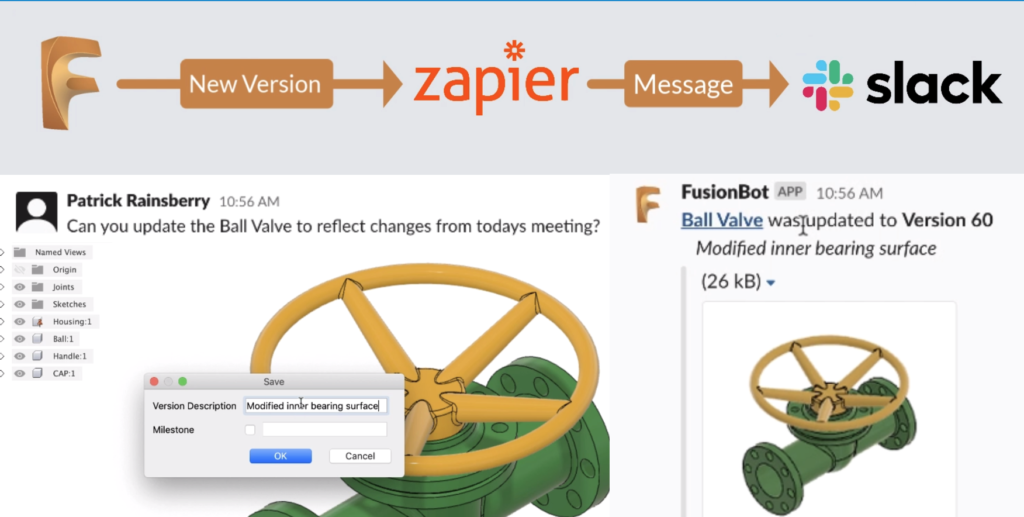

Data Extensibility

With so many of us now working remotely and with distributed teams world-wide, it’s more important than ever that we stay connected as efficiently as possible. We’re working on extending Fusion 360’s capabilities so that you tools you use to stay connected can also be better integrated into your product development workflows. Connecting Zapier with Fusion 360 and Slack will enable you to see Slack updates of Fusion 360 activities.

We love the work you do

Fusion 360 could not become as popular as it is today without you, our community of users. From your personal hobbies to professional projects, we love learning about your work and how you use Fusion 360 as part of your workflow — from getting back at package thieves with Mark Rober‘s ingenious glitter-bomb invention (now in its 3rd iteration) to Ken Block and Rotiform‘s collaboration on how to make the worst and best wheels.

Another awesome project that’s currently gaining momentum is Brian Alldridge‘s design of a better pill container for Parkinson’s patients. The video that first appeared on TikTok user @jcfoxninja’s account showed how the pills prescribed to Parkinson’s patients are way too small for patients to handle. Alldridge decided to develop a pill container solution that functions like a shot glass to avoid the need to handle pills at all. To make the design accessible to anyone, Alldridge made it open source to anyone who wants to use his design and print it. Alldridge had no prior design experience and was able to quickly teach himself Fusion 360 to bring this idea to life.

Stories like these show that you have the power to change lives. Thank you for being the community that you are. We love you, and happy 2021!

If you have any questions about getting started with Fusion 360 or renewing your subscription, we’re here to help. You can purchase Fusion 360 directly from the Autodesk store. If you’d like to speak to a sales representative, please contact the corresponding number to your region:

United States: 1-833-843-3437

Canada: 1-833-843-3437

UK: +44 808 169 9659

Germany: +49 89 412 071 04

Switzerland: +41 31 539 11 46

Italy: +39 02 12 412 0560

France: +33 1 75 85 05 80

Spain: +34 93 122 5042

Poland: +48 22 15 212 44

Belgium: 3228997236

Netherlands: 31237996567

Sweden: 46313619516

Finland: 358753250819

India: +91 8010340891

Japan: 0800-080-4228

Australia: 1800 314 451

____

NOTE:

- Roadmaps are plans, not promises. We’re as excited as you to see new functionality make it into the products, but the development, releases, and timing of any features or functionality remain at our sole discretion.

- The projects mentioned in this roadmap are highlights and do not account for on-going efforts like bug fixes, platform, and service maintenance.

- These roadmap updates should not be used to make purchasing decisions.