Let’s uncover two common causes of modeling failures in Fusion 360 and learn how to avoid them: Singularities and NonManifold Topology.

Have you ever tried to model a shape with Autodesk Fusion 360 and failed? I have, many times! In the previous post in this series, we learned about the 3D Modeling deadly sins of ‘Near Coincidence’ and ‘Sliver Faces’, and we learned how to avoid them!

In this post, we’ll learn why a singularity is not a good thing, and we’ll understand how Fusion 360 uses the concept of Manifold Topology to define our solid objects.

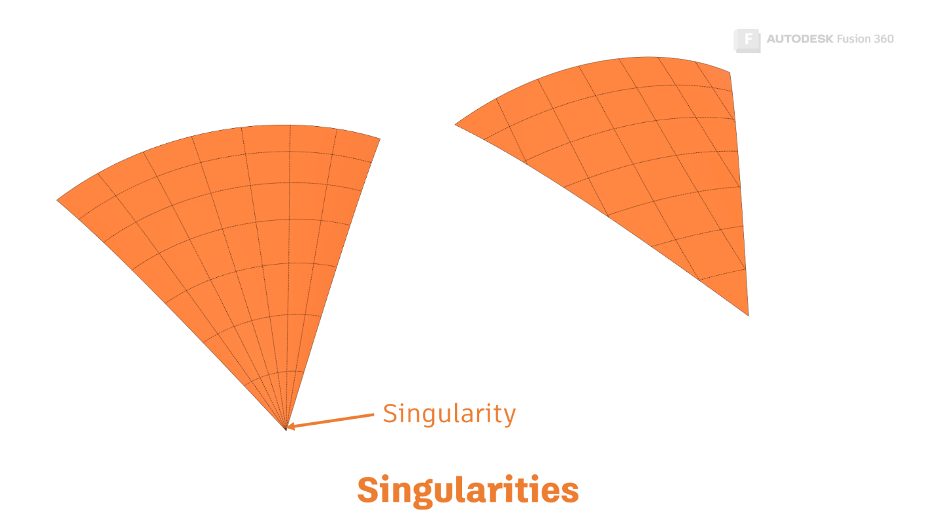

Singularities

In ‘Get Smart with Fusion 360’ Pt. 4, we learned that the Autodesk Shape Manager (ASM) defines a Loft mathematically as a four-sided shape. ASM will fit the lofted surface to the profiles we supply.

If we supply one Edge Section and one Point Section to the Loft command, ASM will create a three-sided loft. The “tip” of the three-sided loft is called a singularity. Singularities can also be formed when revolving a surface.

Singularities themselves aren’t a problem, but they can cause problems downstream, particularly when offsetting surfaces.

If you’re having problems with a non-four-sided surface, the easiest way to diagnose Singularities is with the Isocurve Analysis Tool. If the isocurves converge on a single point, you have a singularity!

If you can, try swapping the problem surface with a boundary patch. The boundary patch tool always creates a four-sided surface that is Trimmed to the input geometry (instead of Fitted) to avoid singularities.

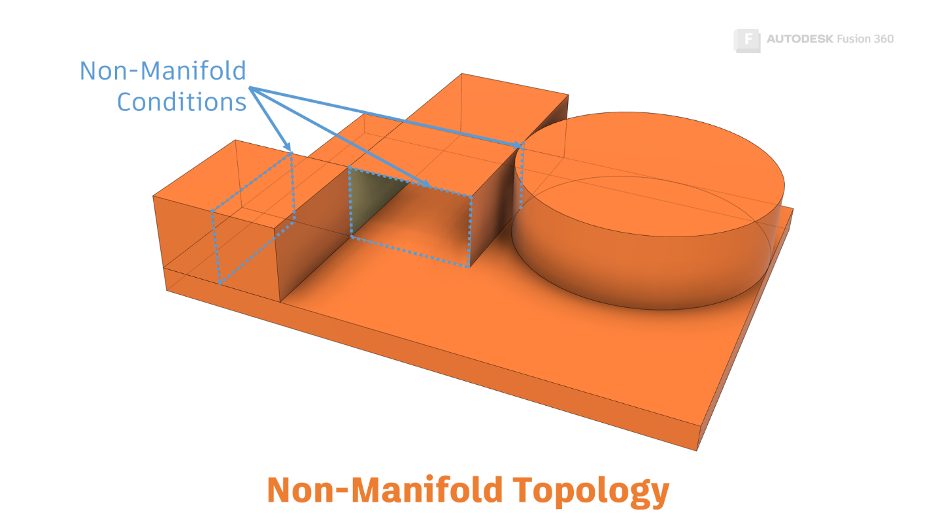

Non-manifold topology

Manifold Topology is the way we describe how Fusion 360 recognizes that a shape is a solid. If the shape is open, Fusion 360 will create a surface model. If the shape is closed, Fusion 360 knows that it has a solid.

There are two conditions for a shape to be ‘closed’:

- Internal voids must be completely enclosed by Faces.

- Faces must have an ‘inside’ and an ‘outside’.

There are additional conditions for a shape to be ‘manifold’:

- Each Edge can only be shared by two Faces.

- Each Vertex cannot be a “pinch” point in the solid (a point where two or more closed volumes join at a single vertex).

You can see that it’s possible for geometry to be both closed and non-manifold. Geometry that fails to meet these four conditions can cause unexpected outcomes.

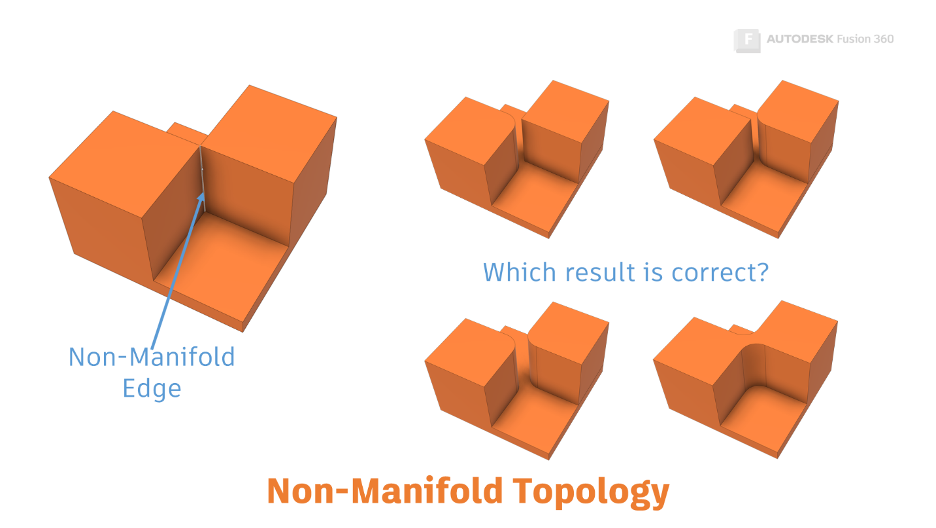

Non-Manifold topology causes ambiguities which Fusion 360 can find confusing. The classic example is two cubes sharing an edge. This edge is non-manifold because four faces share a single edge.

When we try to fillet this edge, ambiguity arises because there are four equally valid solutions. Which solution do we expect?

If you are having trouble with non-manifold geometry, try re-ordering the Timeline, creating multiple bodies, or adding temporary supporting features.

The 7 Deadly Sins of Fusion 360 3D Modeling Pt 4: Loose Tolerances

In the final post of this series, we’ll learn how we can get into trouble if we allow loose tolerances! Read the rest of the series below:

Part 1: High Curvature & Near Tangency

Part 2: Near Coincidence & Sliver Faces

This blog post is based on an Autodesk University class. You can read the handout, download a dataset, and try out some exercises that illustrate the Seven Deadly Sins from the Autodesk University website here: 7 Deadly Sins of 3D Part Modeling in Fusion 360.