This article walks through a few benefits of using Fusion and Okuma Super-NURBS, along with tips for achieving the best possible part finish.

Machining a high-quality, shiny surface finish requires a combination of many different factors to be correct. How the part is set up, the tooling used, and the cutting parameters all affect the result of the machining process. Even more important is the motion of the CNC machine tool. Abrupt changes in the feed rate and jerky motion affect how the machine cuts the material and the resulting finish—typically in a negative way.

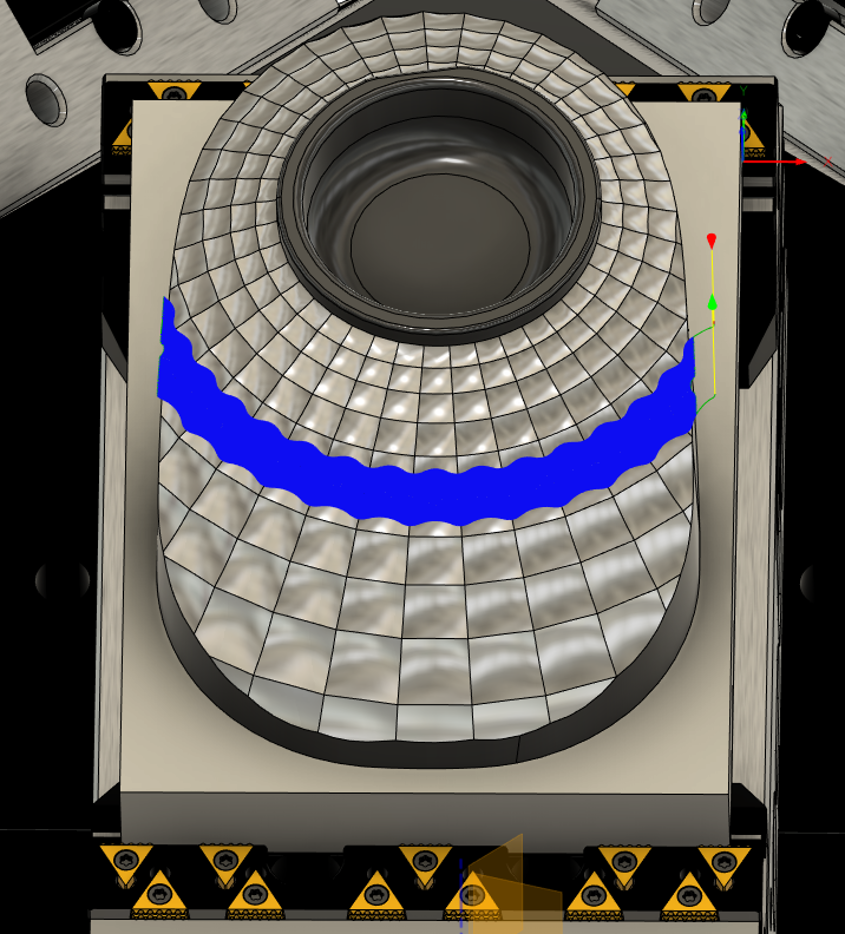

Using Okuma machine tools with the THINC-OSP CNC control and the Super-NURBS programming functionality can aid in machining parts with high accuracy and surface finish requirements. Gosiger’s Engineered Systems Division recently ran a test on an Okuma Genos M460V-5AX machine tool. The result was a smoother machine motion, increased part quality, and a 42% reduction in cycle time.

The test compared two toolpaths for the same part. The first had a tolerance of .02mm and no smoothing applied, resulting in a cycle time of 8:10. The second toolpath had a tolerance of .01mm with a .25mm smoothing value, resulting in a 4:42 cycle time. Imagine what the time savings would be if the entire part was machined with these tools.

Improving the machining process

With Okuma machines outfitted with Super-NURBS, the control loop feed is digital-to-digital. This speeds up the communications process, enabling faster machining. There’s no need for a look-ahead within a Super-NURBS system because it’s inherently fast without it.

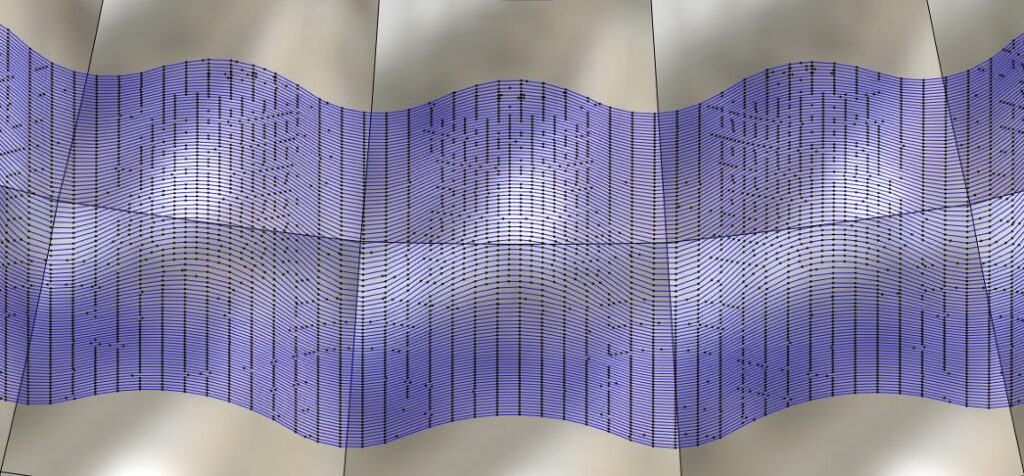

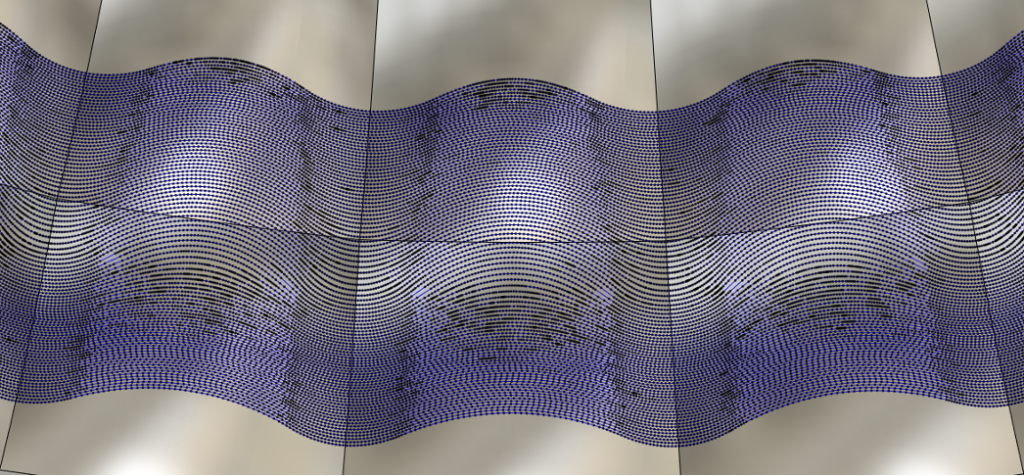

With curvature shapes, CAM systems calculate and output a series of coordinate points based on the tolerance specified in the toolpath. This creates linear segments to create the part geometry. Using a programmer-determined tolerance band with Super-NURBS generates a best-fit spline through these points, resulting in smoother machine motion.

When using Super-NURBS, you need to make CAM programming considerations. For example, a common misconception is that when jerky motion happens, machine control struggles to calculate because there is too much data or points in the toolpath. The truth is the opposite, and typically more data will give you smoother machine motion.

Think of this as playing a game of connect the dots in which you must create a smooth splined curve through two points. But you also must consider the previous and next points. If the points are far apart, this becomes quite difficult. Adding to the difficulty, the curve must also stay within a narrow tolerance band. With points that are spaced much closer together even though there are more points, it’s easier to figure out the shape of the splined curve to increase accuracy.

Seamless toolpath creation

When creating a toolpath in Fusion 360, one way to increase the number of points generated in a toolpath is to decrease the tolerance value, even if it is less than your quality tolerance. Smoothing options and the built-in post-processing tolerance can also affect the number of points in the NC code output. Tailoring these settings to your Okuma machining center helps the Super-NURBS calculation, giving you smoother machine motion and a better surface finish.

When creating a toolpath that you may need to make multiple changes to the settings, such as the boundary, stepover, or leads in order create the final result you desire. A tip here is to increase the toolpath tolerance to a large value. This will reduce the calculation times while you adjust the settings, saving you time. Once you have everything set to the way you want, change tolerance to your desired small value and do a final calculation.

When using toolpaths like Steep and Shallow, which have a smoothing option for Evenly Spaced Points, decreasing the maximum spacing value can help Super-NURBS. This generates a toolpath with additional points that are more consistently spaced. It’s worth noting that when using the HI-Cut Pro function, you can also apply these principles to increase efficiency.

With the combination of Okuma and Fusion 360, you too can generate the accurate and quality surface finishes that you and your customers demand.

Note: The Super-NURBS functionality has its own settings, which we don’t discuss in this article. To learn more about them and for best practices, reach out to your local Okuma reseller.