& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

3 min read

Once in a while, an opportunity comes along for mankind that is so great, so enormous in ambition, only the chosen few can accomplish it. Those brave enough to stare into the abyss of the impossible, and simply retort, “no”. One such group of individuals resides within the walls of America’s Test Kitchen, and with Andrew Rae, better known as Binging with Babish.

Some of you may already be fans of Binging with Babish, or America’s Test Kitchen, both known for their incredible culinary feats, and in Babish’s case, his love letter to films through the medium of cooking. Andrew, and his counterpart at ATK, Dan Souza, wanted to finally climb their Everest, to complete their Magnum Opus, to give the world, real life Uncle Buck pancakes.

Now, at the surface level you might be saying “Ok so they made giant pancakes, doesn’t seem that hard, and what has this got to do with Fusion 360 or me?” Well, giant pancakes need giant utensils, and unfortunately you can’t just get mega pancake sized skillets at your local store. What makes it even harder is even when you have the the right sized utensils, that’s a lot of weight to lift, and unwieldy for humans, even with two people.

So to summarize, we have a need for giant utensils, a large cooking surface which is not readily available, and some method for flipping the pancake that isn’t human powered.

Enter Fusion 360, and an industrial robot that can only be described as “whoa, that dude is huge”

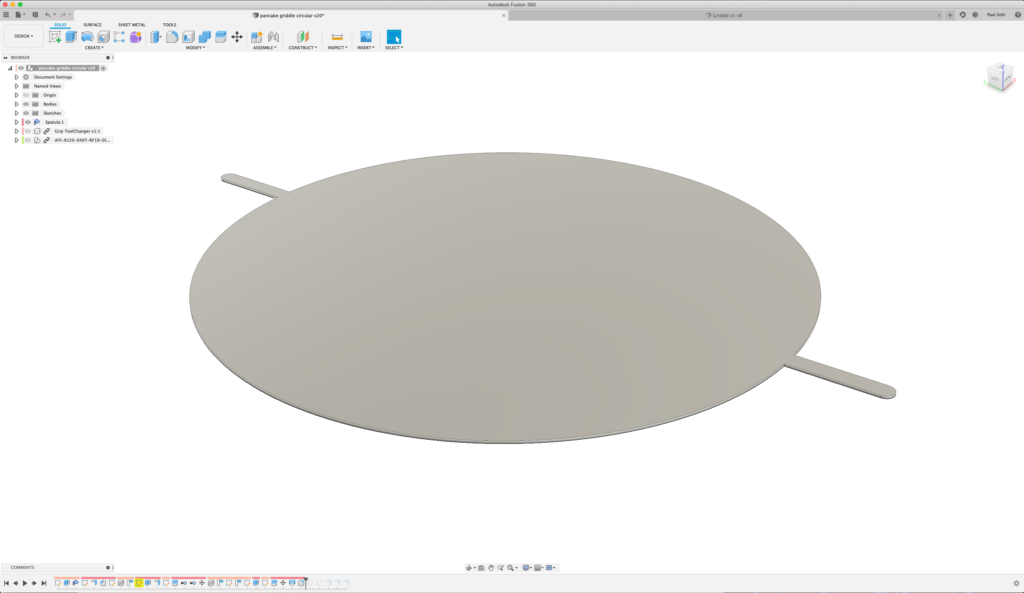

Working in Fusion 360, two seasoned chefs, worked closely with a team of designers and engineers to design and fabricate a made for purpose skillet and spatula.

During the design phase, sheet metal became an invaluable tool, allowing the creation of a large enough work surface to scrape and lift a 40” diameter pancake (1016mm) which was designed really rapidly. Next up, the skillet was modeled with sheet metal too, with both parts being water jet cut, and then sterilized after to be food safe. Don’t worry, they used food grade aluminum for the parts!

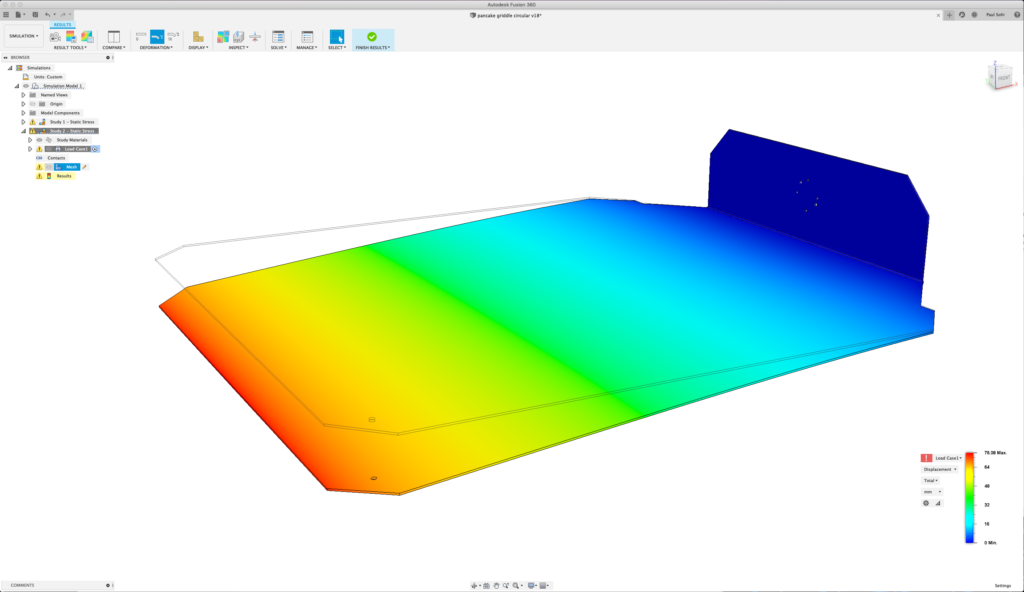

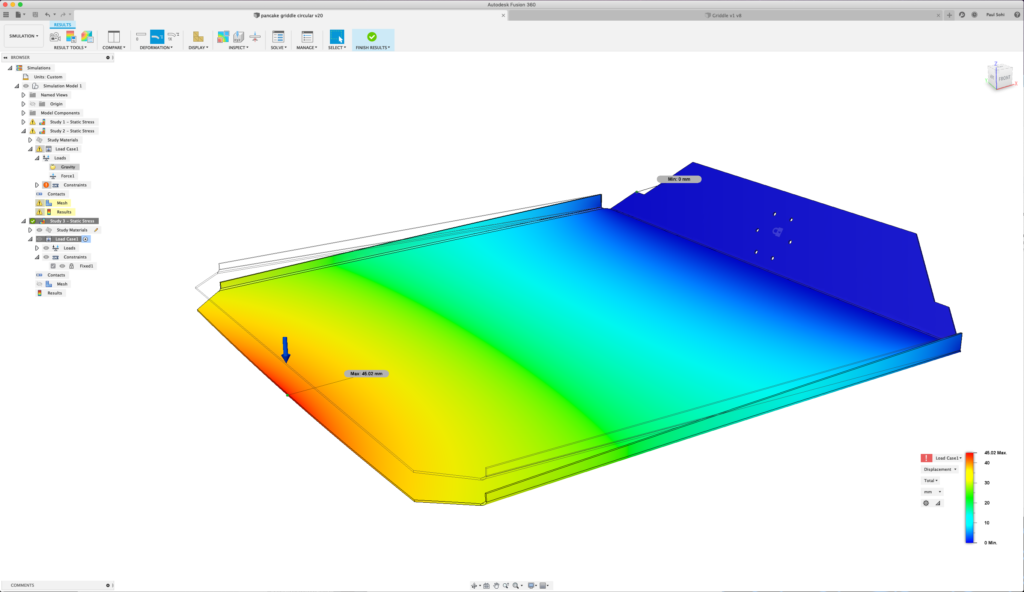

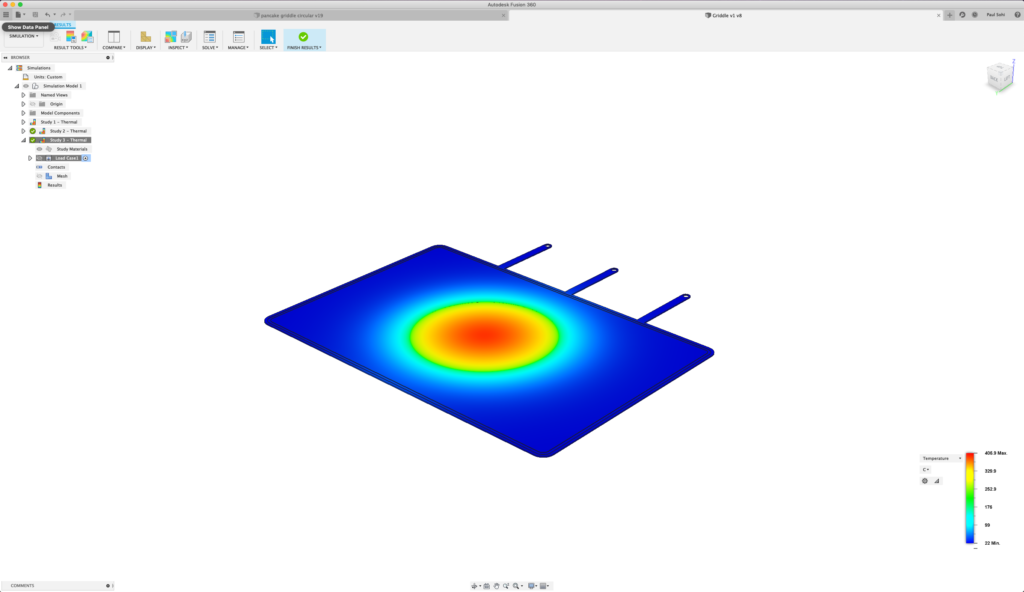

But wait, designing and fabricating something like this is pretty straightforward, but making it work? Whole different game. Making giant pancakes is without a doubt a lot of fun, but there is a significant amount of engineering that needs to go into this before anything is fabricated. Can the robot handle the cantelever from the end effector? Will the spatula itself be able to handle the weight of the pancake? What about the skillet, will it distribute the heat evenly throughout, based on the configuration of the burners they are rigging?

Mercifully, Fusion 360 has us covered! Using a few different simple FEA simulations, and thermal simulations, Dan and Babish were able to determine ahead of time what pain points they might have.

These simulations proved hugely valuable, radically changing the design of the spatula, and giving Dan and Babish a chance to predict where the cold spots would be on the spatula before anything was manufactured.

One of the most valuable bits of information derived from the thermal simulation was that a thick steel plate to operate as a heat sink would make the cook surface much more even!

Ok, so with the design and engineering done, fabrication happened in 2 hours, and everything was ready to go.

We could try and describe the robot, we could even show some photos here, but as they always say “a picture is worth a thousand words” so by our estimates, at 24 frames per second, the 10 minute video Binging with Babish produced is worth 14,400 words, or a Masters Dissertation. Check out the video below!! (Warning, many pancakes were harmed in the production of this video)

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.