Fusion 360 makes electronics to mechanical workflows easy with seamless ECAD/MCAD integration.

Autodesk Fusion 360 is a single unified product development platform that can bring any PCB design to life, no matter its complexity, thanks to features such as:

- Editors for schematics capture, circuit simulation, PCB layout, library management, integrated and powerful electronics, and mechanical CAD capabilities.

- An accurate 3D PCB editor, PCB drawings, and a manufacturing data generator.

- A full suite of MCAD, manufacturing, modeling, simulation, and electronics tools.

In this article, we’ll go over seven Fusion 360 features that make ECAD to MCAD workflows easy.

1. One platform does it all

With Fusion 360, mechanical engineers don’t need to find a standard conversion file format to share information with electronic engineers. Both are on the same platform. Changes to a board generate alerts with options to adopt them. Thus, ensuring that all teams always have access to the latest revisions.

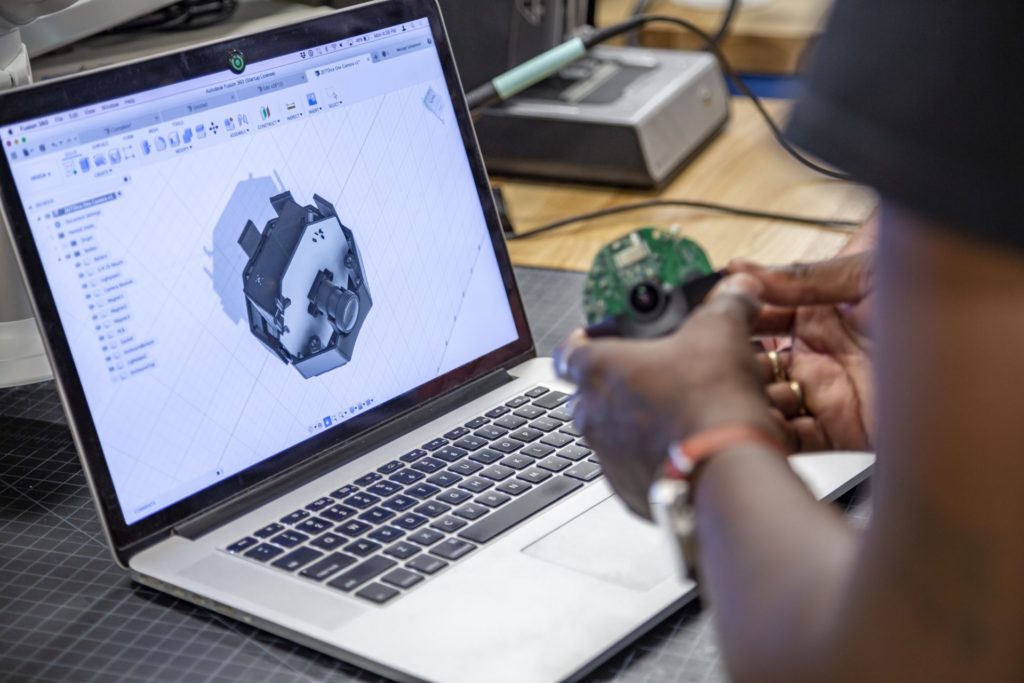

2. Identify design failures early-on

Ultimately, the biggest concern between mechanical and electronics engineers is if the circuit board will fit the component with mechanical assets and if the connectors are aligning correctly. Thus, failure to do any part of this can significantly delay your time to market or, worse, cause costly prototype re-spins. With Fusion 360, you can now virtually identify any failures before you complete your prototype.

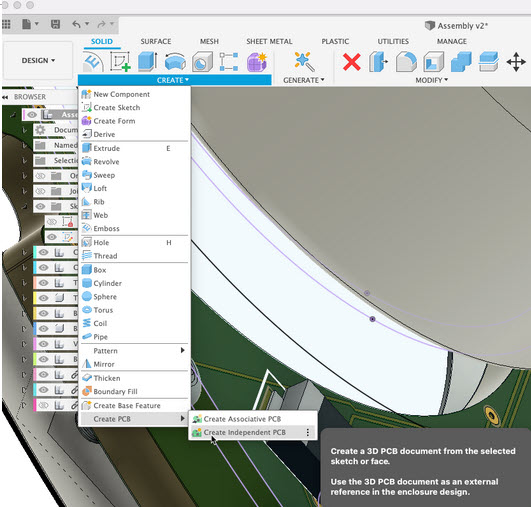

3. Capture complex PCB outlines

We’re continually making changes to give you a better design experience when using Fusion 360. As a result, you now can capture complex board outlines directly from the Fusion 360 design workspace and adopted by the circuit board design workspace. The earlier version of Fusion 360 would arbitrarily select the origin and X-axis in the PCB editor.

4. Capture outline geometry

Providing the correct outline of the PCB based on the enclosure usually entails some sort of file conversion. As a result, this is something you typically continually repeat with every update. In Fusion 360, capturing the outline geometry is as easy as projecting the enclosure surface. The electrical engineer then adopts it after receiving the alert.

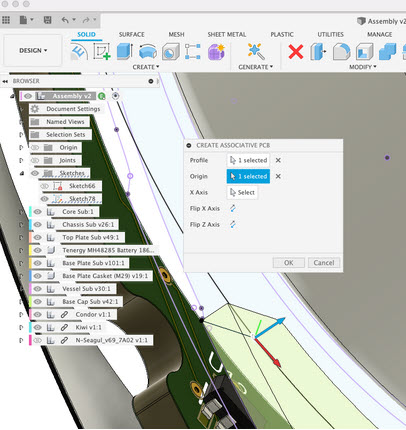

5. Choose PCB outline origin

In addition to selecting the intended profile shape for the PCB, you now have the option to choose the PCB outline origin and its x-axis. This used to be arbitrable chosen for you as the point closest to the page’s origin. With this new implementation, the origin and the x-axis of the circuit board will perfectly match the mechanical workspace profile.

6. Create Independent PCBs

We’ve renamed the options when it is time to select your profile. Thus, you’ll notice that you can Create Associated PCB or Create Independent PCB from the create menu. We recommend using the Create Associated PCB option. Changes to the sketch profile are reflected on the PCB workspace. In contrast, the independent option will only affect the PCB the first time.

7. Electromechanical collaboration

The mechanical engineer can be confident that the PCB designer is laying out the board correctly. This is extremely important for designs with connectors or LED status indicators that need to be correctly aligned with the exposed areas of the enclosure. With this feature, you’ll avoid any orientation errors on the design that can cause time-consuming prototype re-spins.

Ready to engineer, design, and build anything? Gain access to comprehensive electronics and PCB design tools in one software solution for electronics engineers.