Fusion and Formlabs are teaming up to give you more control over your prints—learn about all the new features and how they’ll streamline your additive manufacturing process here.

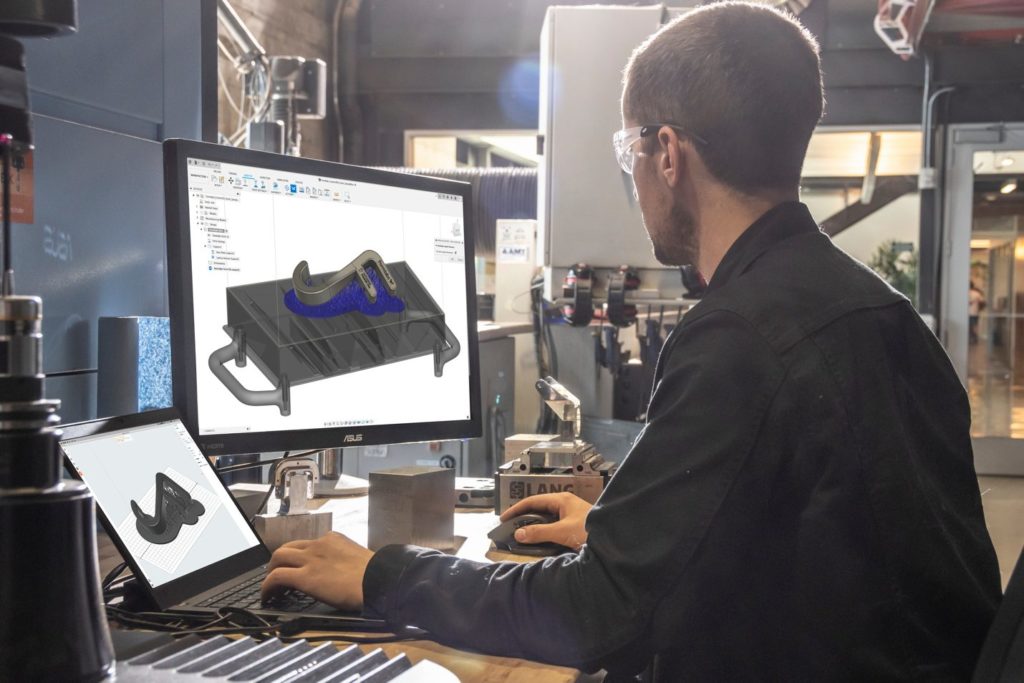

The Fusion Manufacturing workspace is already a feature-rich space for FFF machines, with posts available for major manufacturers, fine support controls, assistive tools to avoid errors when printing, and even custom post configurations. Now, we’re partnering with Formlabs to bring you solutions that extend to SLA and SLS technology, enabling you to capture your design and manufacturing intent in one platform.

Fusion’s Manufacturing Workspace

Before we dig into the details of this partnership, let’s talk about the benefits of the Fusion’s manufacturing workspace for additive workflows. Fusion’s Manufacturing workspace eliminates the need to create STLs for manufacturing by enabling you to push your slice /toolpath data directly to your additive machine. This keeps manufacturing data connected to the design data, eliminating the need to create new STLs to print when there is a design change. The Fusion Manufacturing Extension is a high-performing CAM tool for collaborating with others—it accelerates the metal additive manufacturing phase of a project by folding additive experts into your workflow.

Why would you want to use an additive manufacturing workspace when you already have a dedicated slicer for your machine? Excellent question! Fusion gives you the advantages of fully associative design and manufacturing data, so you can set up your manufacturing model once then regenerate toolpaths any time. Fusion also includes simulation tools that show you how your part will be made and assistive Add-ins to avoid mistakes before they happen.

Fusion and Formlabs

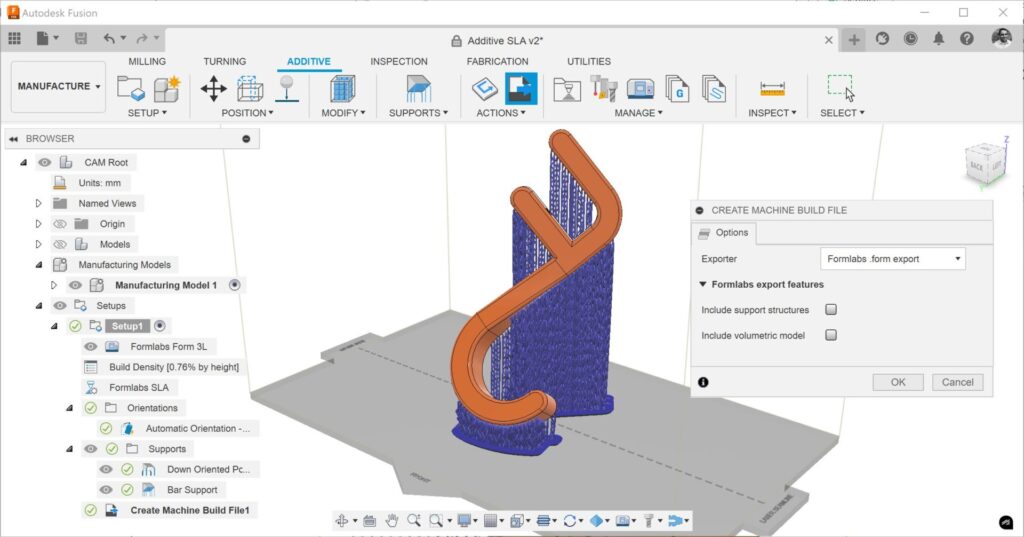

Our partnership with Formlabs brings these advantages to the full range of Formlabs SLA machines, giving you granular control over support structures, baseplates and enabling you to push straight to a form file. Bringing SLA features over to the Fusion additive manufacturing workspace really expedites getting projects made and allows for minimal file management and seamless collaboration. This partnership will also be extended to Formlabs SLS machines soon.

This Formlabs partnership also brings some quality-of-life features to speed up your time to printing. For example, the new Automatic Orient feature in Fusion gives you granular control of your priorities for orientation. Maybe you want support structures to prioritize the footprint of the setup, or maybe the inverse, or something entirely different. Automatic Orient allows you to set your priorities and review several options before sending a project to print. Additionally, the support strategies in Fusion now allow you to print with lattice supports made to your specifications, or use an entirely different support structure strategy, such as bar supports.

Giving more control to you doesn’t end there. This is just v1.0 of the Formlabs integration—we’re not much for one-and-done here at Autodesk. Sualp Ozel, Senior Product Manager for additive manufacturing in Fusion, explains that this partnership is focused on eliminating barriers that slow commercial design and manufacturing. “When applications aren’t connected, productivity suffers, especially during design iterations, as change orders require several file translations and result in loss of detail.” We’re working on even more features that will continue to put you in control of your additive manufacturing process.

In the meantime, have you tried out these exciting new features for yourself? If you’re a Formlabs and Fusion user, we want to hear from you—share your progress and prints on social media and tag @adskfusion360 so we can highlight you.