Check out how Jay Loomis, a graduate student at Brown University, uses Fusion 360 and the Formlabs Form 3 to restore indigenous wind instruments.

Repatriation of art and artifacts has become an increasingly complex issue with museums worldwide. In the United States, the Native American Protection and Repatriation Act became law in 1990 with the mandate to return artifacts to tribes. But, three decades later, progress is still slow. And when Native American artifacts are returned, they’re often in poor condition or even poisonous to the touch, as museum curators used arsenic as a preservative.

Technology is becoming an important part of restoring artifacts to a usable state. Jay Loomis, an ethnomusicology graduate student at Brown University, partnered with Formlabs and a group of other scholars and clinicians to create functioning, 3D-printed replicas of Indigenous wind instruments such as flutes and whistles.

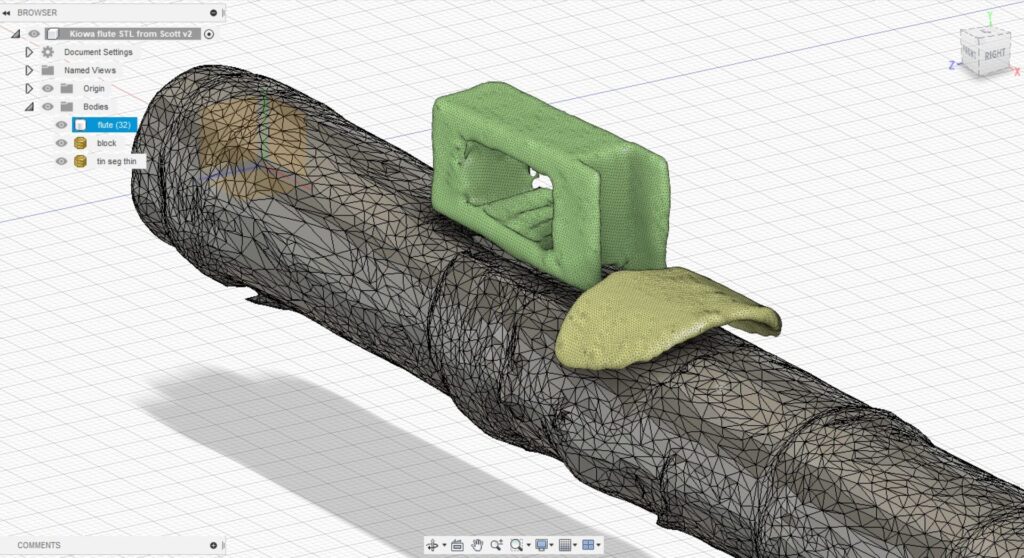

Scanning and 3D printing a new version of a block flute

One particular Indigenous instrument at the center of their project is a Native American block flute in the Haffenreffer Museum of Anthropology at Brown University. It’s dated to approximately 1875-1910. After experimenting on his own and finishing a pilot project using Autodesk Fusion 360 for another instrument, Loomis discovered he could create fully functional, printable replica instruments.

“Once I figured out some basic drawing and modeling functions, it was really easy to build on the knowledge,” Loomis says in a recent Learn Lab article. “The software makes it easy to create bulges, dips, creases, and contours that would be impossible for me to do by hand. I like how easy it is with Fusion 360 to translate an idea in my head into a 3D digital image that I can examine from any angle.”

His process for the block flute included carefully 3D scanning the artifact to create the model in Fusion 360 and using Formlabs Form 3, a stereolithography apparatus (SLA) 3D printer, for the physical replica. Fusion 360 also made it possible to repair the original split wood in the digital model and restore playability to the replica.

Learn more about the project’s journey here.