& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

4 min read

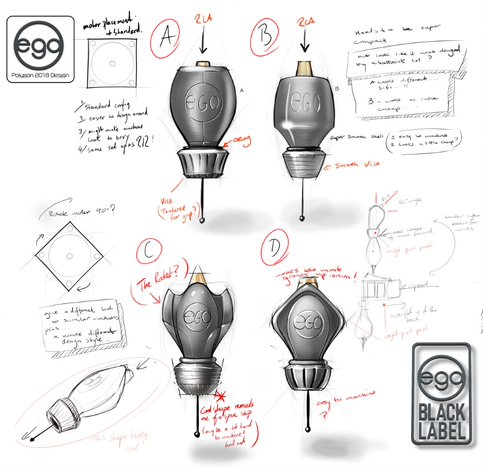

British illustrator-turned-tattoo artist Richard “Bez” Beston had designed stunning and award winning tattoos for international customers for more than 10-years when his thoughts switched to engineering. He realized he could design a better machine than the one he was holding. The incumbent machines were heavy, noisy and the constant vibration of the motor made his wrist ache, a common problem for tattoo artists. He also had strong ideas about how several features of the machine’s design could be improved.

Luckily, he found Autodesk Fusion 360.

Already familiar with the Autodesk brand from his former career as a video games illustrator, as a microbusiness Bez qualified for two free licences of Fusion 360, and began to self-train using YouTube videos and online tutorials. “I tend to smash buttons until it does what I want it to – call it perseverance,” he half-jokes. He found that Fusion 360 is quite simple and intuitive to learn for a beginner with a designer’s background. The alternative was a competitor’s full price product for about £9,000. “We had no money so this was not really an option,” he adds. “Fusion is ideal for a start-up business. It’s been brilliant for us in terms of accessibility, capability and it is intuitive to learn.

Through trial, error, and that same perseverance, Bez first developed the prototype then final production designs for a new line of lightweight, quiet, and accurate machines under the “EGO” brand. That was four years ago: fast forward to today. Now there are three models – EGO Vertex, V2 and the new pen-like Switch. They have taken the global tattoo market by storm, selling well over 3,000 products a year. There is a growing order book to countries including China, Germany, France, the UK, and soon to crack one of the biggest global markets, India. Customers find the lighter weight and low noise a huge benefit in a job that requires hours of patient drawing and small, repetitive wrist movements.

Key to EGO’s popularity is a more fluid, quieter needle mechanism that drives the needle into the skin. It has more adjustment to suit the different styles of tattooing that artists prefer.

Firstly, Bez redesigned the mechanism from a coil system on the older, heavier machines to a rotary system, using customized lubrication-free bearings by igus – another Autodesk customer. The lighter, lubrication-free standard bearings damp the needle mechanism in the early Vertex models. The later V2 model uses a new linear needle motion, converting rotary motion to a linear drive using rails. This produces more accurate puncturing and has removed the side-to-side vibration that other machines often produce.

Bez also devised the proprietary “power triangle system” built into the EGO. This is a rubber damping system based loosely on a car suspension’s rubber bushing. “Colour coded, each rubber insert produces a different grade of feel to fine-tune the tattooing effect,” he says. “At one extreme the needle pushes into the skin and it takes longer to come out. Turning the damper around gives you a softer hit but quicker retraction, for a different tattooing effect.”

A combination of the igus plastic bearings, a more fluid linear action, lighter weight, smaller size and the innovative rubber molded grip – also designed by Bez – makes a product that consistently reduces wrist strain, vibration and noise. This allows artists to work on customers for hours with no strain and less noise. Some of the igus parts are custom-made to Bez’s design. “We wanted zero maintenance for our machines so the igus plastic bearings were essential and they have custom-made them to my design,” he says.

Fusion 360 has been “brilliant” as an accessible tool that does exactly what Bez wanted. “I could not have designed these machines and got this growing market without Fusion,” he says. Objectively, there have been some niggles and its not 100% perfect, he says, but he admits that with no formal training the software could not have been better to work with for developing these products.

And tattoo machines are only the beginning for the artist-cum-engineer.

Bez’s manufacturing operation – currently a workshop above his 12-booth tattoo studio in central Sunderland, UK – moves to a larger facility in three weeks. The building was selected to accommodate phase one of his grand plan, a “creative hive” to bring makers and engineers back to Sunderland and the North East of England. Amateur or professional designers and engineers can book time, design and make prototype products using tools like desktop 3D printers, simple lathes and bench-top tools – using Fusion 360 to create their dreams.

Bez’s first new product is a prosthetic device to support the back, assisting people with back pain and, potentially, multiple sclerosis. “We want to create a space that inventors and “imagineers” can come and design, experiment and make stuff. This is what I did and my products sell, so others can do it too. The North East is a creative region and we now have the digital tools to spark a mini-manufacturing revolution here.”

And since an article in UK national newspaper The Times, Bez has been given a room to coach designers at the Sunderland Council Software Centre.

And it’s all thanks to a creative mind, hard work and Autodesk Fusion 360.

Try Fusion 360 for free today.

For more about Bez, the EGO machine and TripleSix Studios, visit: https://www.youtube.com/watch?v=1xhFmxgJKJY&t=58s

For more information about Autodesk Fusion 360, visit: https://www.autodesk.com/products/fusion-360/overview

For more on igus self-lubricating bearings visit: https://www.igus.co.uk/iglidur/plain-bearing

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.