This post is also available in: Français (French) Italiano (Italian) Deutsch (German)

In this three-part series, we’ll cover three key tools the Fusion 360 Machining Extension brings to the table that will make your process more efficient than ever — next up is toolpath automation, including steep and shallow and hole recognition tools.

Starting a business is easy — said no one ever. Running a successful company begins with a great idea, but it never stops there. Business owners in the design, engineering, and manufacturing industries are often bogged down by daily decision-making — from hiring machinists to client relations to purchasing new machines. But, thanks to Fusion 360, there’s one decision you don’t need to overthink: selecting a CAD/CAM software. This three-part series covers three key tools the Fusion 360 Machining Extension brings to the table that will save you time, energy, and money. Let’s dive into Toolpath Automation to see how our Steep and Shallow and Hole recognition tools let robots do what robots do best: run unattended.

Toolpath Automation

Toyota wasn’t wrong when they created the Kaizen Way. Continual improvement is crucial to landing jobs, growing revenue, and improving profit margins. It’s not as easy as it sounds, though. Increasing revenue and expanding margins requires a lot of time and logistics. Meanwhile, most manufacturers are already consumed with just keeping their machines running, employees happy, and lights on.

The tools you decide to use play a crucial part in making all of these tasks easier so you can focus on your businesses’ long-term success. The Fusion 360 Machining Extension and its Steep and Shallow and Hole Recognition tools are one way to automate your process to run leaner, more efficient, and more marginally robust.

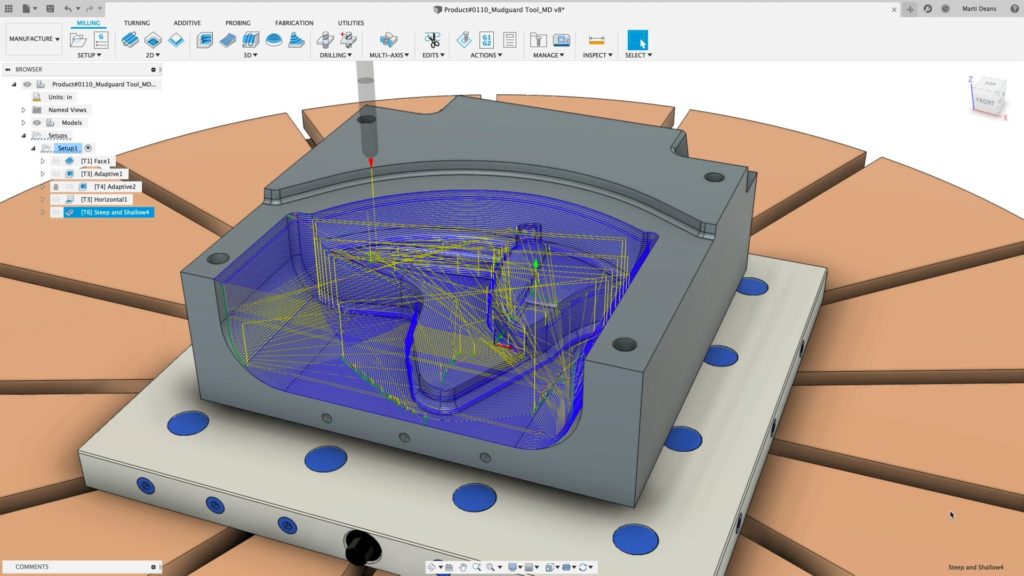

What is Steep and Shallow?

Steep and Shallow automates the finishing of freeform surfaces. It automatically detects the surface slope and applies the optimal strategy. Even when part complexity increases, automatic collision avoidance can provide the control you need to machine your parts, utilizing the full 5-axis capability of your machines for better access, and using more rigid, shorter tools for improved surface finish.

Steep and Shallow is a lot more than “set it and forget it.” Using it in your everyday practice can help speed up your CAM process and, by default, your machining process. It also helps onboard new employees when you’re standardizing around a process, enables you to get to a great place before you hone your finishing strategies, and so much more.

The integrated design and manufacturing environment is a massive value proposition for anyone with two departments designing and making parts using Fusion 360. Programmers are automatically notified of new versions, allowing you to regenerate toolpaths on the latest design quickly. This ability lowers the costs associated with design changes because you’re always using the latest version of the design.

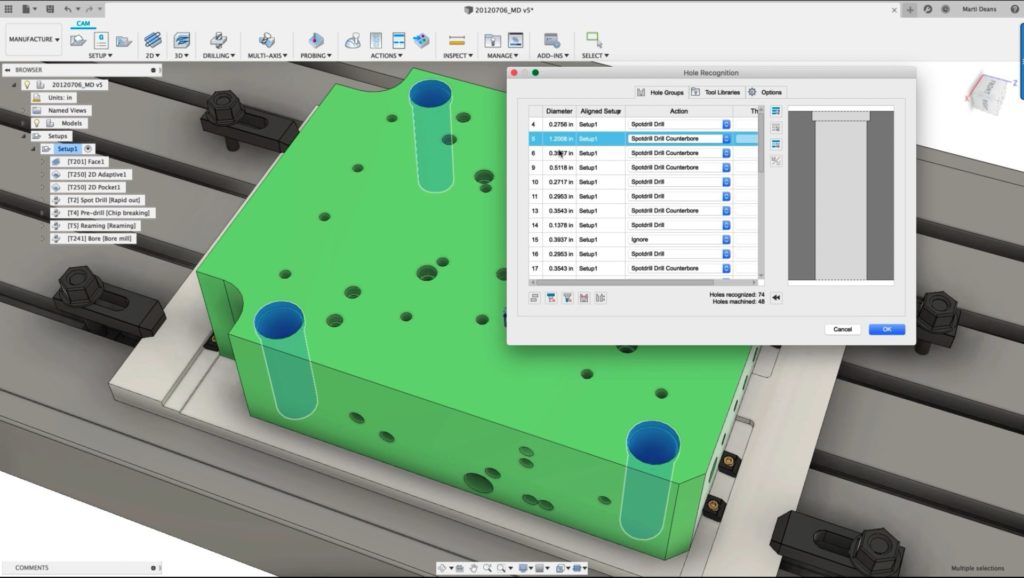

What is Hole Recognition?

Hole Recognition is another tool that helps make your process more efficient. Let’s say you are in the after-market automotive sector or industrial fittings sector. You often work with either the need for weight reduction or you’re making loads of hole or pocket features for threads or pass-throughs. Most of your time is spent selecting every single little hole and part for hours — or at least that’s how it feels. Real talk: let’s hope you don’t accidentally click off a feature and lose your work.

Hole recognition lets you create templates and click-and-go tools so that you can apply specific cutting methods to types of holes. Fusion 360 automatically finds the same features and batches them together. Regardless of chamfer size, thread size, hole diameter, or depth, the Machining Extensions Hole Recognition tool is an anti-bang your head against the wall tool that can seriously make you money. Check out this video to learn more:

Try the Fusion 360 Machining Extension Before You Buy

If you can add functions to your daily work life like a QC department run by one machine and one CAM specialist using one platform, why wouldn’t you? If it’s fear of cost, learning curves, or complexity, well, don’t worry. Access a 7-day free trial of the Fusion 360 Machining Extension to see how much your process can change for the better.

Check out Part 1: In-Process Inspection and Part 2: Rotary Strategy of this series for more information.

Want to learn even more about the Fusion 360 Machining Extension? Check out these webinars:

Why Steep and Shallow is a Reason to Upgrade to the Fusion 360 Machining Extension

Why Surface Inspection is a Reason to Upgrade to the Fusion 360 Machining Extension

Why 4th Axis Rotary is a Reason to Upgrade to the Fusion 360 Machining Extension