This post is also available in: Français (French) Italiano (Italian) Deutsch (German) 日本語 (Japanese)

Learn how automating the nesting process with the Fusion 360 Nesting & Fabrication Extension saves you valuable resources.

Manually nesting your parts for manufacturing is a timely, non-value-added process that results in excess material usage. Automate this process with the Fusion 360 Nesting & Fabrication Extension to create optimized and associative multi-sheet and multi-material nests in preparation for cutting on CNC machines.

Reduce costs

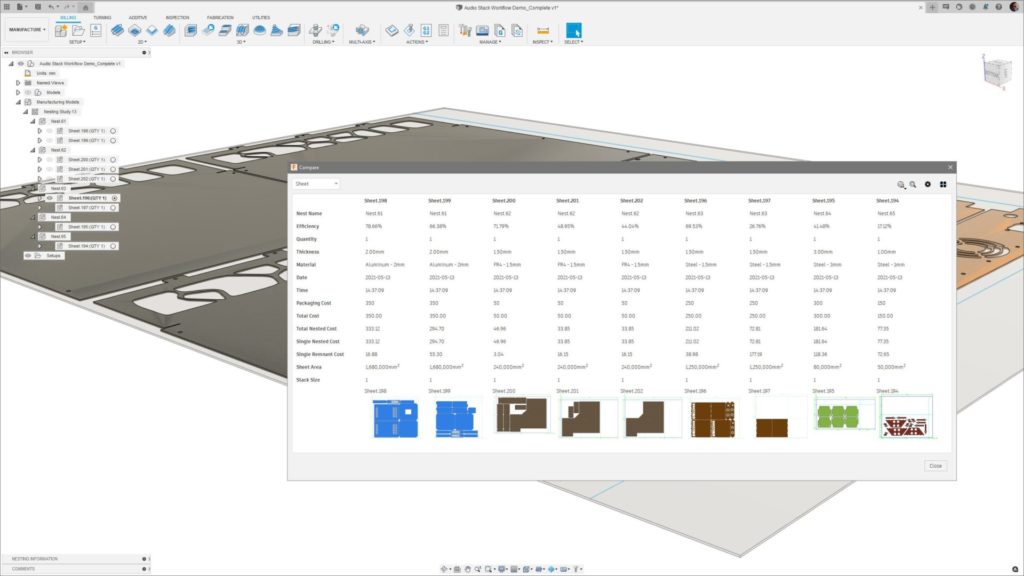

Comparing different strategies to reduce costs is easy when you can create multiple nest studies side by side in a single document. The Compare dialog can help you make data-driven decisions about your manufacturing strategy for every job. Here are a few parameters that can be modified and compared:

Material costs

A cost value can be associated with each packaging option, defined in the Process Material Library. This value determines the cost of your nest studies — it even considers the remnant material. After creating multiple nest studies with different packaging options and strategies, you can use the compare dialog to make data-driven decisions. In turn, this identifies the most cost-effective solution.

Material sheet size

Stock material comes in various sizes and each has its own cost. After populating the Process Material Library with multiple options, the Nesting & Fabrication Extension can determine if it’s more cost-effective to use a smaller sheet size at a higher quantity or go with fewer, larger sheets.

Quantity

Maximizing your material yield is paramount in ensuring you are as cost-effective as possible. On the flip side, manufacturing quantity can significantly impact your material usage. Creating multiple nest studies with different quantities allows you to compare material usage and achieve better results. So, why not even integrate multiple external documents into a single nest to further reduce your costs?

Reduce programming time

Repetitive tasks and excessive manual operations lead to significant programming time. The Fusion 360 Nesting & Fabrication Extension minimizes your programming time and maximizes your manufacturing time with built-in intelligence and automation. Here are a few key features that can minimize programming time:

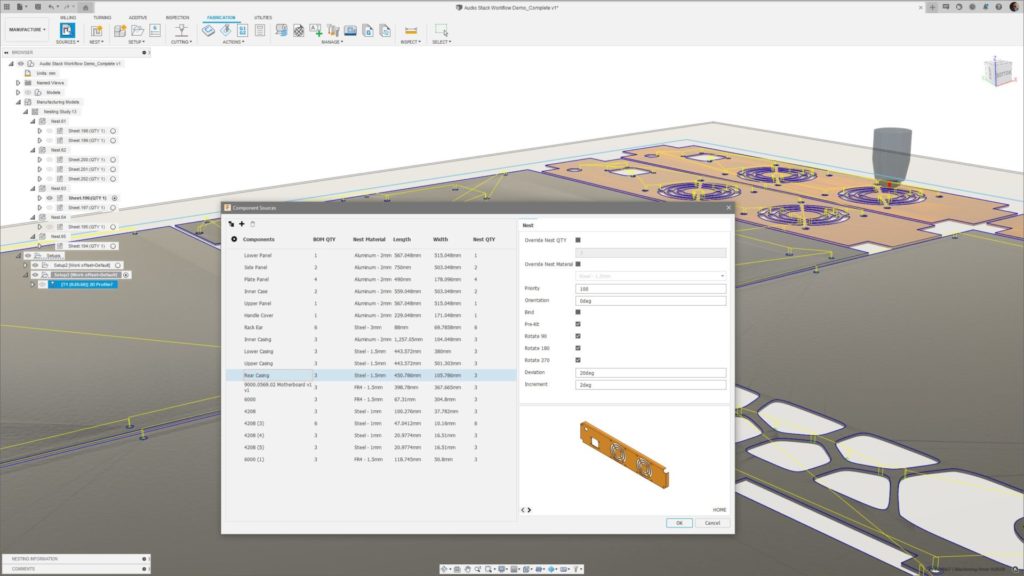

Materials and thicknesses

Assess material usage across an entire assembly or range of parts by automatically identifying and separating your parts into different materials and thicknesses. All this happens automatically with the Nesting & Fabrication Extension, saving you significant programming time.

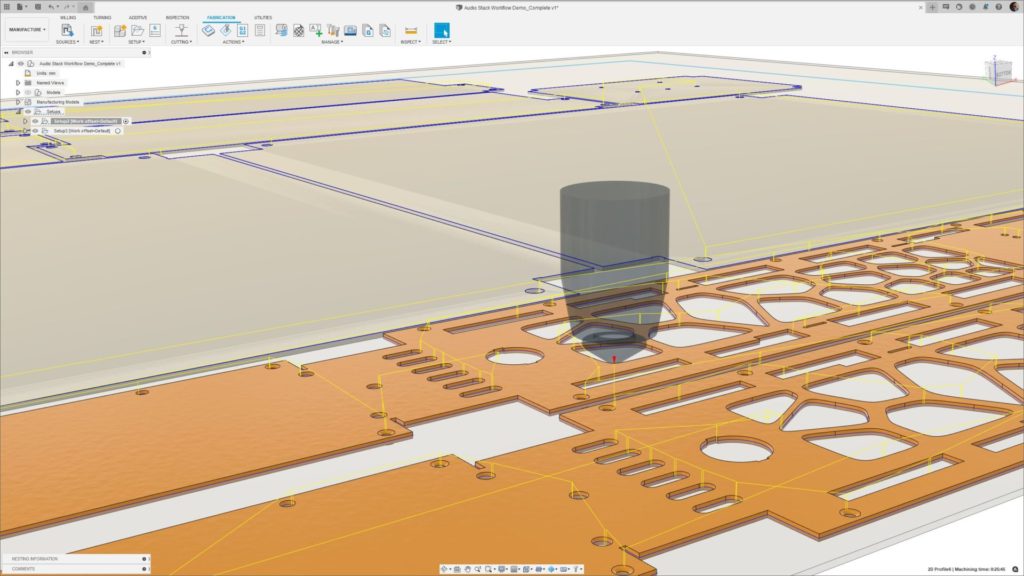

Setup automation

When it comes to manufacturing and creating toolpaths, step one is to create setups. A setup defines your stock material, coordinate system, and the models you want to machine. The Nesting & Fabrication Extension automates this process by using built-in intelligence gained from the nesting process.

Templates

Creating toolpaths gets repetitive. Toolpath templates in Fusion 360 can store repeatable operations and minimize time spent on programming your parts. Once you create the toolpaths, store them in the template library and use them time and time again. Additionally, anyone working in the same Hub can also collaboratively benefit from these stored templates, promoting part consistency across your business.

Minimize rework

Changes are inevitable — but how we adapt to them makes a real difference. Whether it’s a simple change to the allowable rotations of a part or a fundamental design change, the Fusion 360 Nesting & Fabrication Extension is fully associative. Nesting automatically consumes any changes.

Design changes

Integrated CAD/CAM solutions are changing how we view the design and manufacturing process. The Nesting and Fabrication Extension is no different. It consumes changes from the design workspace with a simple regeneration to ensure you are constantly working on the most up-to-date version of your designs. Nest studies are flagged as outdated after a design change occurs, which acts as a visual indicator to regenerate.

Manufacturing changes

Adaptability is key to ensuring you are always ready for anything. The Nesting & Fabrication Extension provides adaptability by consuming any changes you make during manufacturing, such as changing sheet size, allowable rotation, item separation, and much more.

Learn more about the Fusion 360 Nesting & Fabrication Extension

Whether you’re looking to minimize non-value-added work, cut costs, or reduce programming time, the Fusion 360 Nesting & Fabrication Extension offers you the toolset to enhance and automate your workflows. Learn more about using this extension via our learning portal. And for an up-close and personal look at how to use the Nesting & Fabrication extension, explore these webinars:

Optimize material yield with automated nesting

Optimize material yield and reduce programming time with automated nesting