Back in January we released sheet metal in a limited preview for Fusion 360. The goal of the preview was to get feedback on sheet metal rules and flange, while the team finished work on flatten.

Rules

Rules

Based off research and feedback, we have found that people who use sheet metal typically have 5-10 different materials. However, a majority of them don’t take the time to create rules that reflect the materials. Our objective is to make it so easy to create and reuse a rule, that our users all have a custom library.

One Flange

One Flange

Depending on the CAD package, there are any number of different “flange” sheet metal features. While planning, we kept coming back to one question. Rather than taking the extra time to pick features up, why not pick based off of selection? Our flange tool creates a base, contour, edge and join flange. Not only is this faster for experienced sheet metal users, it is also easier for new ones.

What we learned and improved based off feedback– Editing and creating new materials was not discoverable. In the beginning we had “duplicate rule” as a way to make a new rule based off of a current rule. We learned that this complicated things and changed it to a “new” button. There was also confusion around use and editing of samples rules. Based off of feedback, we changed to a default library where users can edit and customize to fit their needs.

For flange, there has been a lot of good feedback around the simplicity of the tool. However, one thing we missed was flange width discoverability. In July, there will be enhancements around the dialog dropbox and soon after our initial release in context options.

What else we learned – Beyond the improvements to flange and rules, one big discovery was around workflows. I didn’t take into account how much our press/pull and move tools are loved and/ or used. Due to the insights of our users, we are going to enhance these tools to follow the sheet metal rules. The work on this will start after our first release.

A new update is coming

In our upcoming May update “drum roll”, we’ll be adding flat patterns!!!

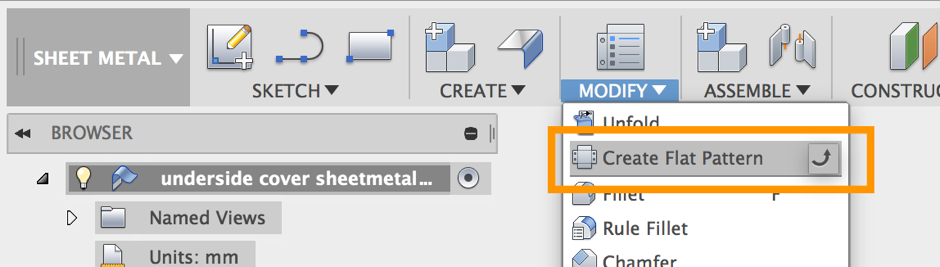

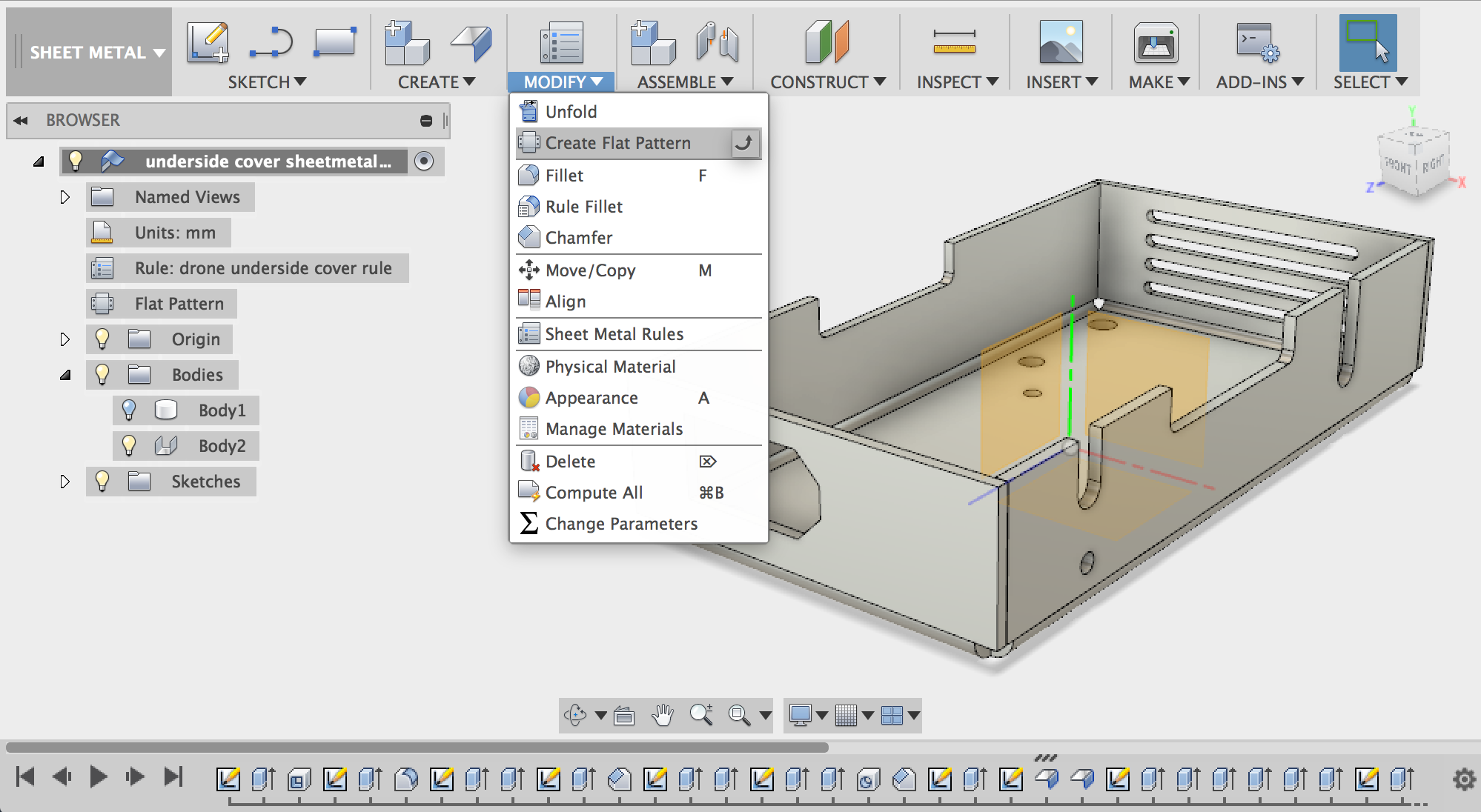

You will be able to create flat patterns of your sheet metal designs! Access it under the modify drop-down menu in your sheet metal preview workspace.

Once it’s active, select the face you want as stationary, and it’ll flatten your part. Notice that if you already have a flat pattern, Fusion 360 will ask if you want to activate the existing one.

A flat pattern is modal, so once it’s created, you’ll have to “Exit Flat” to get back to the bent model.

So what’s the difference between flat pattern and unfold? Flat pattern now lets you edit your bend thickness and K factor, whereas if you just did an unfold without the flat pattern tool, those values were not editable.

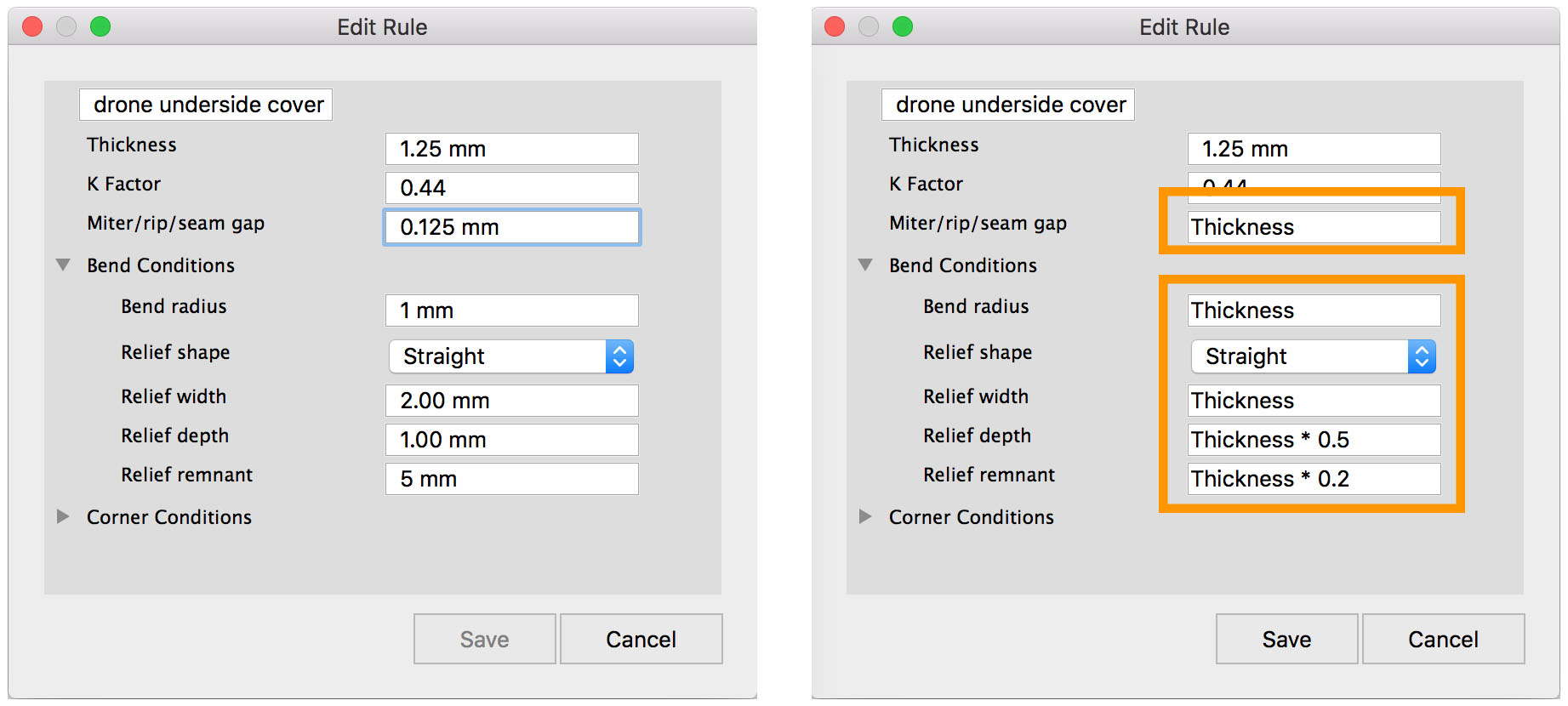

We have also improved sheet metal rule values defined as functions of thickness

In standard sheet metal rules, most dimensions are multiples or fractions of the material thickness. However, these values were previously all hard-coded, meaning that changing the thickness of the material required all of the other values to be updated manually.

Values can now be defined as parametric functions of the sheet metal thickness, by referring to “Thickness” in the expression (e.g. if your bend relief depth should be half of the material thickness, you can type “Thickness / 2” as your Relief Depth value, and this will calculate the value using the rule’s thickness). The included rules library has also been updated to take advantage of this.

Sheet metal flat pattern and bend lines for 2D drawings are also coming

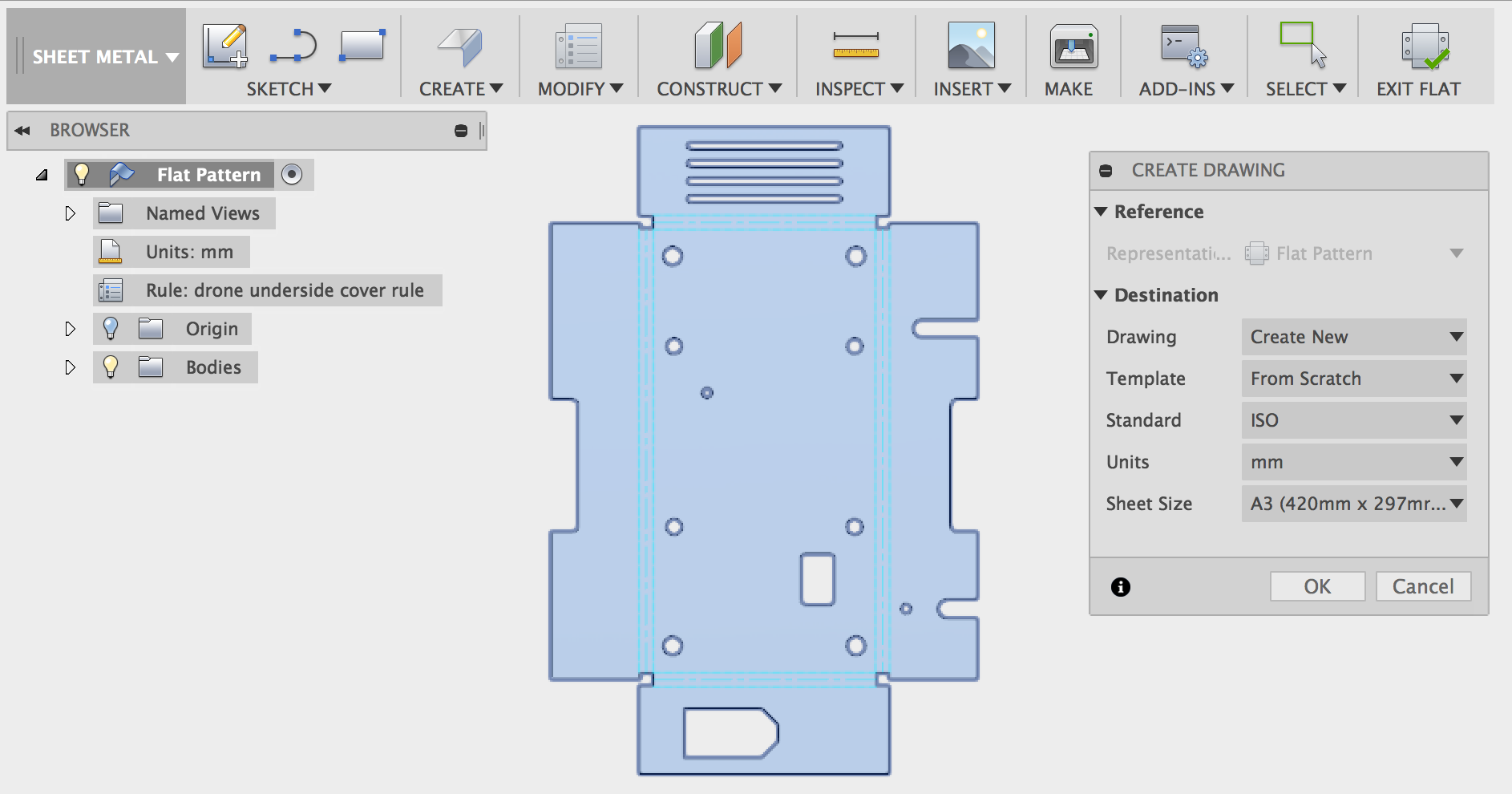

For those of you who are part of the preview, you’ll be happy to know that you can now create 2D drawings of your sheet metal flat patterns. First, create a flat pattern of your sheet metal part by going to the modify drop-down menu and select “Create flat pattern”.

Once you’ve got it, hop over to the drawings workspace and create a drawing from the design. Notice that the representation is now a flat pattern.

Once it gets transported to the 2D drawings workspace, you’ll have all the existing 2D drawings tools at your disposal.

Notice that you also have the ability to show or hide bend extents by checking/unchecking the option in the Drawing View dialog.

Associative bend tables and bend datums, and bend notes are not available yet, but they are currently in development and will be available in a future update.

What’s next you ask?

Our target for the public release of sheet metal is July 24th. At this time, sheet metal will be taken out of preview and available for all. Once sheet metal is released, we will be focused on providing a solution to the following workflows:

Workflow 2: Reuse of other CAD SM models. This new workflow will allow you to open another sheet metal model made from a different CAD package, change the rule and flatten.

Workflow 3: Convert to sheet metal. Using this workflow you can start with a shape that represents the sheet metal design as a volume. You will then be able to select faces connecting the flanges to convert the shape to a sheet metal model.

Nesting: Automated nesting of sheet metal components.

This is an exciting time for Fusion 360! I look forward to all of your feedback and insights as we continue to add functionality to sheet metal. Look out for a upcoming post about our sheet metal challenge as we approach release.