& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

3 min read

The Fusion Factory Experience is back and better than ever at Autodesk University 2023, and we have a very special product lined up for this year’s event.

The Fusion Factory Experience started at Autodesk University 2016 as a way to give attendees a hands-on experience of the concept-to-production process in Autodesk Fusion. Every year since, our team has designed, developed, and produced a brand-new consumer product to share with you all at Autodesk University. We’ve designed everything from an air quality sensor to an electric name badge.

With Autodesk University 2023 right around the corner (November 13-15) and with this year being Fusion’s 10th anniversary, we can’t wait to share this year’s very special Factory Experience product with you. Drumroll, please!

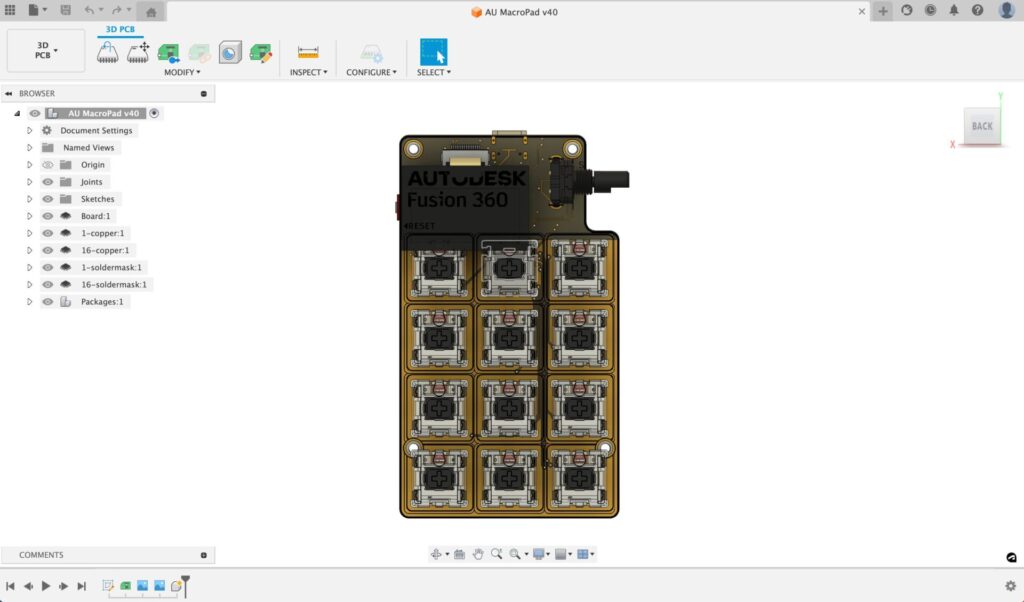

Based on the Adafruit Macropad, this customizable keypad is the perfect companion for any Autodesk app. It has 12 keys, a digital encoder, and an OLED display. The process behind it includes many manufacturing methods like additive, CNC, and injection molding.

At the Factory Experience, you’ll be able to choose your favorite Autodesk app and have the keys CNC etched with the most used command icons.

We chose this product for many reasons. It’s easily programmable with ever-growing code libraries, and with the Raspberry Pi RP2040 Chip + 8MB Flash memory, the sky’s the limit for what this thing can do.

It’s customizable with Cherry MX switches, so you can swap out the ones we provide with whatever special clicky switch you like. It’s a great example of consumer product manufacturing, showing you all the awesome things our software and our partners’ machines and services can do.

To bring this idea to life, we phoned our internal Fusion experts to lend us a hand. Here’s a behind-the-scenes look at our design process and how you can learn more at Autodesk University.

We took advantage of integrated ECAD/MCAD tools in Fusion, which enabled us to design and create electronic structures while integrating the models directly into mechanical systems. This ensured that every stakeholder was included in the product development cycle. Design changes are automatically managed, which let us revise our board shape and component placement and update the enclosure in real-time.

Want to learn more about MCAD/ECAD integration at Autodesk University? Register for this Autodesk University class. Curious about how to use ECAD/MCAD? Learn more here.

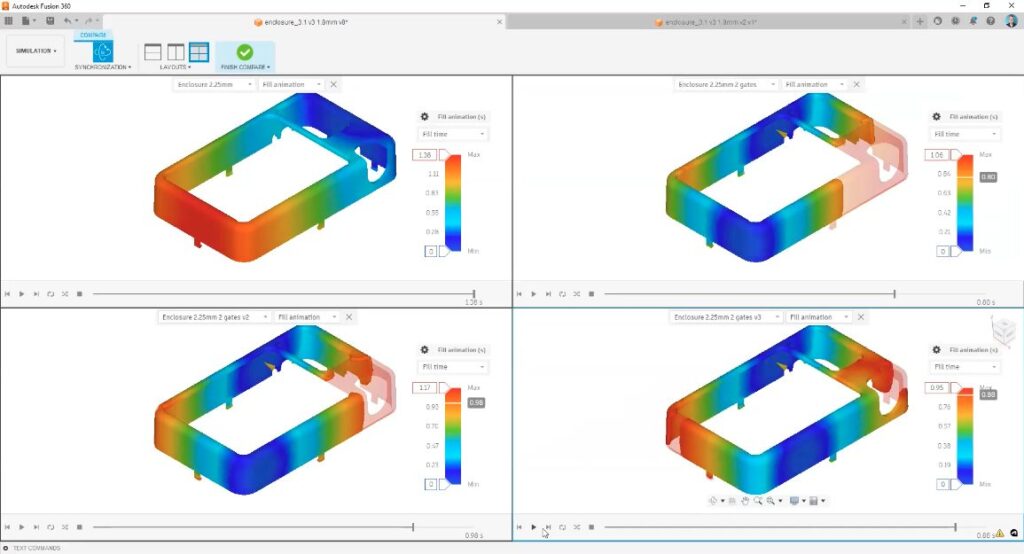

When designing the injection molded enclosure, we relied heavily on collaboration with our other members. Together we figured out what was going inside, where it would be located, and what tolerances were needed so everything could run smoothly.

Once we understood our constraints, we focused on design for manufacturability. We tested the part’s feasibility by using injection molding simulation in Fusion. This helped us end up with a product that was ready to be injection molded and produced at a high volume straight out of the box.

Designing for manufacturability allowed us to maintain our manufacturing bias throughout the whole process. So, instead of redesigning the whole enclosure over and over again, we simply made our initial part one that could be produced right away.

Fusion Factory Experience registration opens on-site at Autodesk University 2023, and the event is ongoing throughout the conference. Be sure to stop by the Factory Experience factory floor in person to reserve your spot.

Want to learn more about how we used the Product Design Extension and injection molding simulation to create the factory product? Register for this follow-up class online ahead of the event.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.