& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

3 min read

Autodesk Fusion‘s machine simulation empowers users to detect collisions, optimize setups, and refine tool paths with confidence. Key features like real-time warnings, simulation timelines, and NC code integration streamline workflows and improve precision. This tool helps machinists enhance efficiency, reduce surprises, and achieve seamless multi-axis machining.

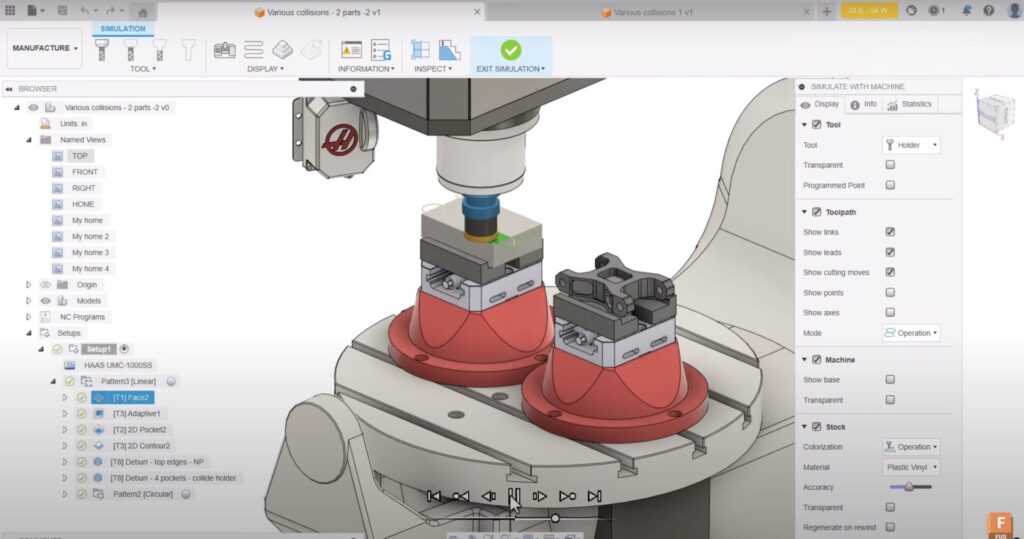

Machine simulation in Autodesk Fusion has become an indispensable tool for users, especially those working with multi-axis machining. This powerful feature offers a comprehensive way to diagnose and address potential issues, ensuring tool paths and setups perform as planned. By detecting collisions and highlighting them in red during simulation, Fusion empowers machinists with the confidence to refine their setups and avoid costly surprises on the shop floor.

Collision detection in Fusion goes far beyond identifying crashes. It aids in selecting the right tools and tool lengths, optimizing part positioning on the table, and verifying tool paths. With this level of insight, machinists can avoid surprises that disrupt workflows. Adjustments to setups and processing plans can be made quickly, saving time and ensuring efficient use of machinery and tools.

Fusion’s ability to detect collisions between tools, machine components, fixtures, tool holders, and stock enhances overall reliability. While the current focus is primarily on milling, this feature is available for lathes and other machines, making it a versatile resource across machining applications. However, linking moves between tool paths are not yet checked for collisions—a functionality Autodesk is actively developing.

Fusion streamlines the simulation process by allowing users to begin watching simulations while calculations are still running. If an issue is detected, a warning box pops up immediately, highlighting problems as calculations continue. Once completed, this box updates to show the total number of issues, errors, and warnings, offering a comprehensive overview of potential concerns.

Users who prefer real-time intervention can toggle the Stop on Collision feature, halting the simulation as soon as a collision is detected. For added convenience, the simulation timeline provides detailed control, enabling users to focus on critical points. Red segments on the timeline represent collisions, and hovering over these segments allows users to zoom in, expand the view, and examine changes in collision states. Black lines indicate transitions in collision status, making it easy to identify and address specific issues.

Fusion’s simulation features don’t stop at collision detection. Users can interact with the simulation timeline to gather detailed information, either by hovering over points or clicking on them for a more thorough analysis. Additionally, users can now view the NC code generated by Fusion during the simulation.

This functionality allows machinists to track the NC code as the simulation runs or jump to a specific point in the timeline and review the corresponding code. Conversely, clicking on a line of NC code will redirect the simulation to that exact moment, providing an intuitive connection between the simulation and the generated code.

For a broader perspective on simulation results, users can click the Issues button in the toolbar. This feature organizes simulation warnings and errors in a user-friendly format, making it easier to understand and address areas of concern.

Autodesk Fusion’s machine simulation tools redefine confidence and precision in machining. By detecting collisions, highlighting potential issues, and providing tools to refine setups, Fusion enables machinists to produce efficient and accurate tool paths. The ability to analyze NC code and view granular simulation details further enhances its utility, making it an essential resource for modern machining workflows.

Ready to elevate your machining processes? Explore these powerful features in Fusion and see how they can transform your workflow.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.