Part 1 of this series will cover the Autodesk Shape Manager and some key 3D modeling terminology to have in your vocabulary.

In this series, ‘Get Smart with Fusion 360 Modeling’, we will find out how Fusion 360 generates shapes for us. As a result, we’ll gain a better understanding of how we can achieve the geometry we want. For example, Did you create a sweep with Autodesk Fusion 360 today? That’s a trick question! I know you did, but you may not have used the sweep command to do it. Stay tuned to find out what I mean.

In the meantime, Part 1 will cover the Autodesk Shape Manager and some key 3D modeling terminology to have in your vocabulary.

Introducing the Autodesk Shape Manager (ASM)

To generate 3D shapes, Fusion 360 calls on the Autodesk Shape Manager (A.S.M). ASM is a modeling ‘Kernel’ – a software component that calculates 3D shapes. Fun Fact: ASM is also used by AutoCAD and Autodesk Inventor (among others).

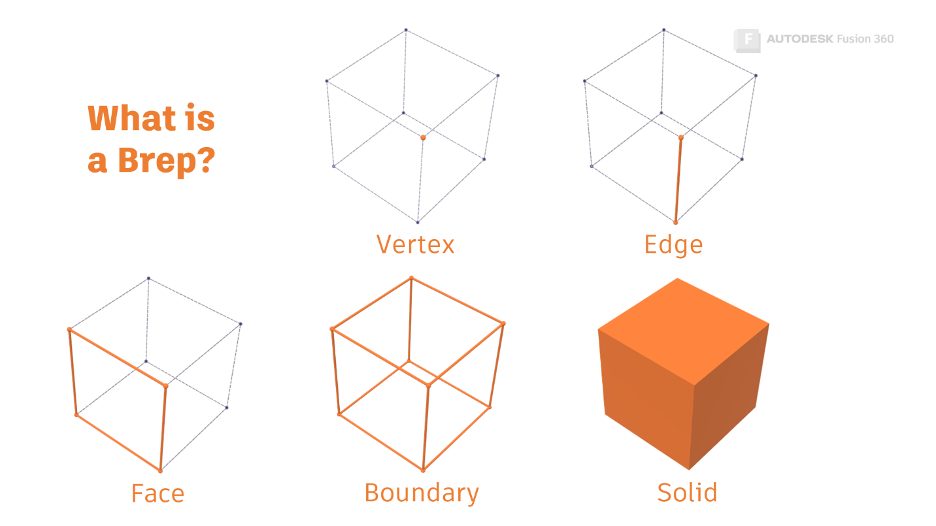

ASM uses the Boundary Representation (Brep) method of calculating shapes. Breps are shapes based on Vertices. Two vertices can define an edge. A loop of edges can define a face. A collection of edges defines a volume (a 3D shape).

When we create 3D forms In Fusion 360 from commands such as Extrude, Sweep, or Loft – we are using the Fusion 360 user interface to pass coordinates to ASM, which calculates the Brep and passes it back to Fusion 360 to be shown on your screen.

Important terminology

Let’s make sure that we are all using the same language when we talk about shapes inside Fusion 360.

Geometry & Topology

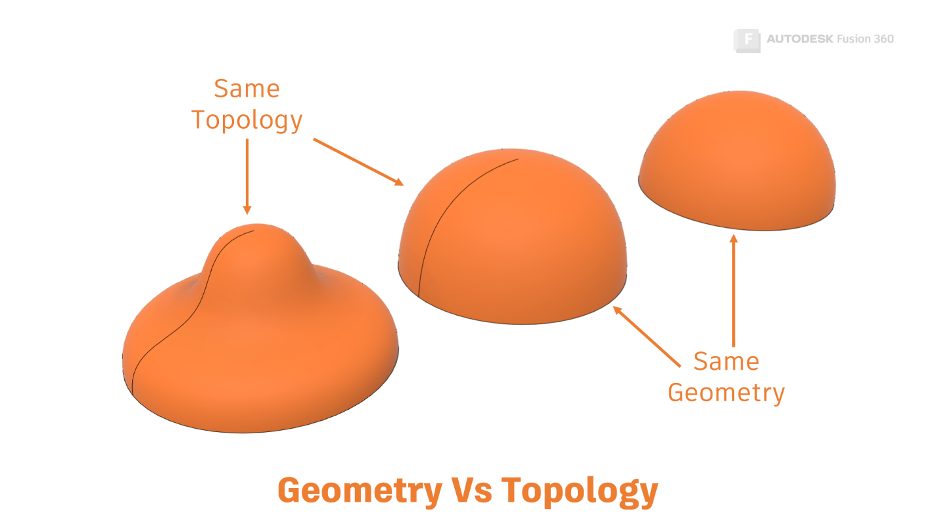

Geometry can be thought of as the shape we want to create. Topology is how we get there.

The same geometry can be created using different topology. The same topology can be used to create very different geometry.

- Geometry – the mathematics that describes the shape.

- Topology – The vertices, edges and faces that form the shape.

Normal

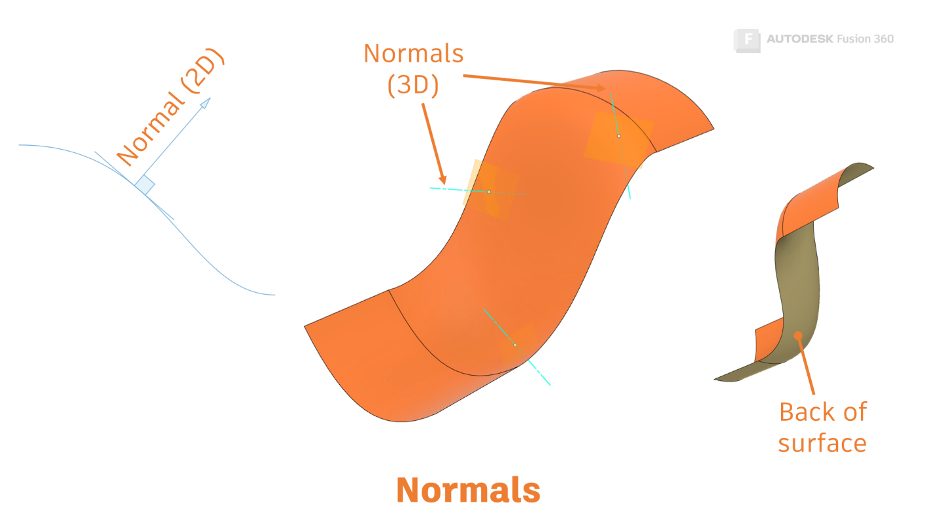

‘Perpendicular to an edge or surface.’ For a solid model, the normal must always point ‘outwards’ from the solid volume. In Fusion 360, the back of a surface is indicated by a ‘Golden’ color.

Curvature Continuity

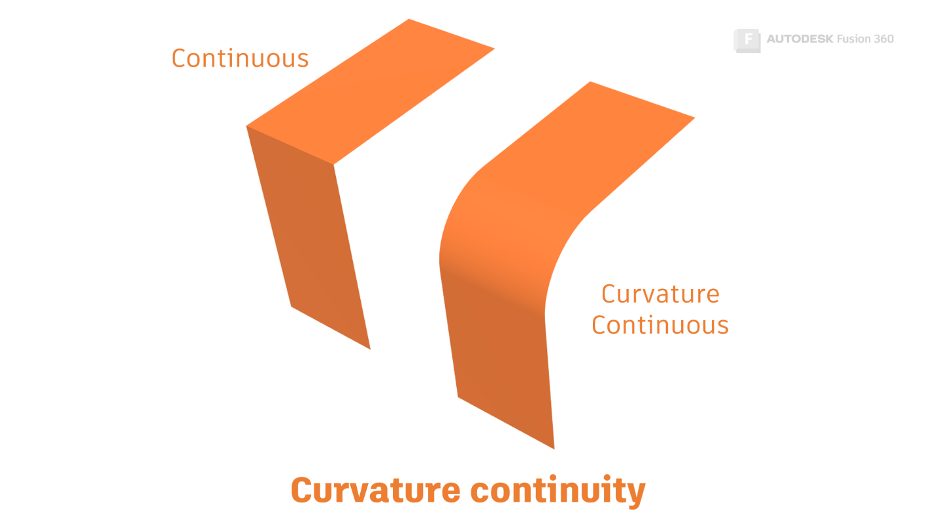

When we would like to create a smooth transition between two surfaces, we can describe the condition as ‘Curvature Continuous’.

Curvature continuity is the process of matching properties across two surfaces. We describe these properties using the letter ‘G’.

The properties are accumulative – G3 continuity includes G2, G1 & G0.

- G0 Continuous: The edges meet (also known as ‘Touching’ or ‘Position’).

- G1 Tangent: The surface normals match along the meeting edges (A fillet).

- G2 Curvature: The amount of curvature matches along the meeting Edges.

- G3 Acceleration: The rate that the curvature changes is equal, leading into the meeting edges.

Note: Mathematically, you could describe additional levels of ‘G’ (G+), but they won’t help us create awesome models.

Get Smart with Fusion 360

Check out the other articles in this series:

What Is a Sweep in Fusion 360?

The Secrets of the Loft Command

What’s the Difference Between Loft vs. Patch?

This blog post is based on an Autodesk University class. You can watch a recording of the class and download a handout that goes with this presentation from the Autodesk University website here:

7 Deadly Sins of 3D Part Modeling in Inventor & Fusion 360