& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

7 min read

When used correctly, CNC programming codes, specificially g-code is an invaluable tool for CNC machinists, allowing you to take full advantage of your machine’s capabilities.

Programming is a fundamental skill for all types of CNC machining, even as automation and new technology seem to be replacing programming tasks. Every machinist still needs to understand how their programs and tools work. Whether you’re new to CNC programming and its most common language, G-code, or you’ve been writing code by scratch for years, CNC programming codes can still feel like a foreign language. And to make things worse, every machine speaks a different dialect you have to understand. Do you understand what they’re saying? Here are the G-code programming basics and g-code language you need to know to efficiently understand and write programs that produce high-quality products.

G-code is a programming language for CNC that instructs machines where and how to move. Most machines speak a different “dialect” of G-code, so the codes vary depending on type, make, and model. Each machine comes with an instruction manual that shows that particular machine’s code for a specific function.

G-code stands for “geometric code,” and follows some variation of the alpha numeric pattern:

N## G## X## Y## Z## F## S## T## M##

N: Line number

G: Motion

X: Horizontal position

Y: Vertical position

Z: Depth

F: Feed rate

S: Spindle speed

T: Tool selection

M: Miscellaneous functions

I and J: Incremental center of an arc

R: Radius of an arc

Alpha numeric codes are used for G-code programming as they are a simple way to:

For example,

G01 X1 Y1 F20 T01 M03 S500

would generally indicate a linear feed move (G01) to the given XY position at feed rate of 20. It is using Tool 1, and the spindle speed is 500. Miscellaneous functions will vary from machine to machine, so in order to know what the m-code means, the machine’s instruction manual will need to be referenced.

Everything a machine can do is based on three basic types of motion:

Every G-code tells the machine which variation of these basic motions to perform, and how to perform it.

X and Y are Cartesian coordinates for horizontal and vertical position, and Z represents the depth of the machine. These alpha numerals will follow the motion/function command (G) to declare the position of the machine.

Next, F determines the feed rate (for feed moves or circular moves), while S determines the spindle speed. T is used to select a tool. Other alpha numerals used in programming might include I, J, and R, which have to do with arc centers and radii.

The line of a program might also include m-codes, which are generally CNC machine codes that tell a machine how to perform an action. While not guaranteed to be the same across machines, some common, standard m-codes are:

Just like a light will stay on until it’s turned off, G-code functions (on controllers that support modality) will remain active until they are deactivated by another code. In other words, only one function can be active at any given time. To deactivate a function, just select a new function.

For example, say a CNC machine code begins with a linear rapid move at X1 Y1 (G00 X1 Y1). If the next function is another linear rapid move, it is not necessary to write G00 again. All that is needed on the next line of CNC machine code is the new position (say, X2 Y2) because the modal condition is the same. Then, to change the function to a linear feed (G01), programming G01 on the following line would deactivate the linear rapid move and activate the linear feed.

Once a condition is set, it stays active until it is turned off or another condition overrides it.

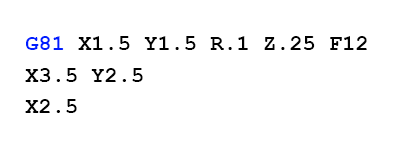

Canned cycles are a kind of modal condition that incorporates all the motions to complete a common task into one code.

For example, oftentimes G81 is code for a basic drilling function. In the case of basic drilling, the tool would have to be 1) moved to the starting point of the hole’s location, 2) rapid to the clearance plane, 3) fed to the depth, and 4) rapid out. That would be four lines of code in the program that would have to be repeated for every new drill position! With the canned cycle G81, only the hole locations need to be specified after activation. Canned cycles like G81 significantly reduce the amount of code by incorporating multiple motions into one code.

In G-code, some other common canned cycles exist for peck drilling, counter boring, and tapping.

Modal code groups allow there to be multiple codes on a single line, but there can only be one code from each group on a line. This is because codes within a group will override each other.

The modal groups for G-codes are:

A postprocessor is a translator that translates the calculated image of a toolpath on your computer screen into the language for machine control. You can create a postprocessor by searching for a sample program that aligns closely with your machine and then amending the program to precisely fit your machine.

Ready to start using G-code to program your machines? Begin by reviewing your machine’s unique coding chart. Remember, every machine is a little different. A Haas’ CNC machine code for a function might not be the same as an Anilam’s code for that function. You have to know which CNC programming codes your specific machine uses for the tasks you want it to perform.

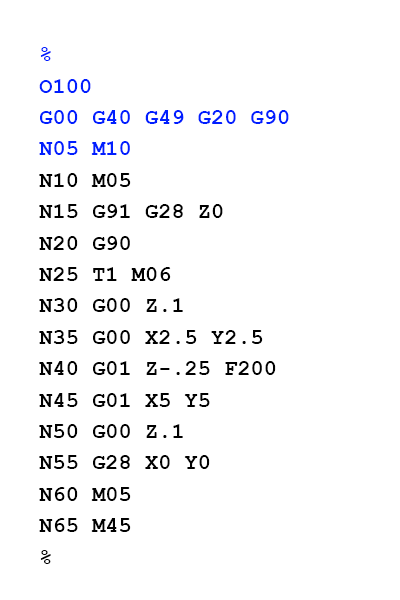

The program will often start with an initialization code (%), followed by a program number. Then, there will be a line of safety codes. Next will be a line for tool change. This puts the appropriate tool in the machine and set the speed to be used. The bulk of the program will then be the machine movements and positioning.

If using line numbering, it’s a good idea to name each line in increments of at least five. This way, if you need to add lines of code later, the lines will still be labelled in order.

When you’ve finished programming your G-code, you’ll typically end the program with a series of functions that stop and reset the machine so it’s ready for the next time.

When used correctly, G-codes are an invaluable tool for CNC machinists, allowing you to take full advantage of your machine’s capabilities.

Integrated CAD/CAM solutions like Autodesk Fusion continue to streamline the CNC coding process, so you don’t have to program parts by hand using G-codes. Producing high-quality parts has never been faster with G-code programming.

By clicking subscribe, I agree to receive the Fusion newsletter and acknowledge the Autodesk Privacy Statement.

Success!