GoWesty makes and sells parts for 1968-2003 Volkswagen Buses, Vanagons and Eurovans. The Los Osos, California based company originally operated as a vintage Volkswagen repair and restoration shop coupled with a parts retail shop, but with the advent of the internet, their business model slowly shifted away from the traditional brick-and-mortar model to an engineering house focused on the creation of high-quality modern solutions that address the shortcomings of these relatively vintage vehicles. The GoWesty design and engineering teams develop hundreds of new products annually, and their online shop sells a mixture of these in-house solutions alongside readily available off-the-shelf platform parts imported from European manufacturers.

“During our years of servicing and refurbishing these vehicles, we identified many areas that needed thoughtfully engineered solutions. There were many parts that were either breaking all the time or no longer available, and we also saw scores of opportunities to create new products to enhance the safety, comfort, and usefulness of these iconic vehicles. We rolled up our sleeves and got to work on the transition from product resellers to product creators,” says Brian Hardoin, Managing Mechanical Engineer at GoWesty. “Each month, we bring scores of new products to market. These solutions directly support repair and restoration facilities around the world, in addition to hundreds of thousands of private owners installing our products in their home garages as they follow expertly crafted step-by-step instructions that we include with the majority of our product lines.”

GoWesty also takes its dedication to #vanlife to the next level by offering a destination for van owners to visit during their travels. “We’re right in the middle of San Francisco and LA, so we get a lot of people driving through,” says Oren Klein, Mechanical Engineer at GoWesty. “We’re a pit stop on that classic Highway 1 road trip.” The GoWesty team greets visitors with a place to park, hang out, and talk about their vans with experts. “During a normal day, we’ll always have a lot full of buses and vans outside our office. People drive in from all over the country, and we keep track of where each visitor comes from,” says Hardoin. The GoWesty team keeps a large map covered in colored pins that mark each traveler’s home town.

Hardoin and Klein point out that even if a van part was originally designed to last a very long time, every part naturally has an age limit. Many parts found in each original van model are all starting to break at the same time, so their owners need solutions that will keep their vans on the road for years to come. “If an owner can’t find a part they need, sometimes they will just stop using their van entirely, and it eventually ends up in a car lot and won’t run. A lot of what we do comes from the mindset of trying to keep these vans on the road for as long as possible from a sustainability standpoint.”

GoWesty designs and sells two types of parts: the parts that keep the vans on the road from a functionality standpoint and the parts that keep the vans more comfortable to live and work in. “We’re doing design work all over the van—everything from modified engines to fun aesthetic modifications and storage solutions for inside the vans,” says Hardoin. “Anything to keep them running or to make them more enjoyable, we’re doing it.” Sometimes, the team discovers modern parts that are adaptable off another vehicle that will work better than a part originally on the van, and other times they dream up modern solutions, such as a useful center console organizer (one of GoWesty’s most in-demand products).

In order to determine which parts are worth designing or modernizing, the GoWesty design and engineering team conducts strategic research. They check online van forums, keep a log of what customers frequently call in and ask for, and they even have a junkyard on site that they sell used parts out of. “If we suddenly sell out of a certain used part, we know it might be something worth making,” explains Hardoin. When creating these new parts, quality and price for the customer are at the forefront of the team’s minds. “As much as we want to make some fancy low volume parts, we think there’s a lot more benefit to trying to get as everything as accessible as possible to the van community.”

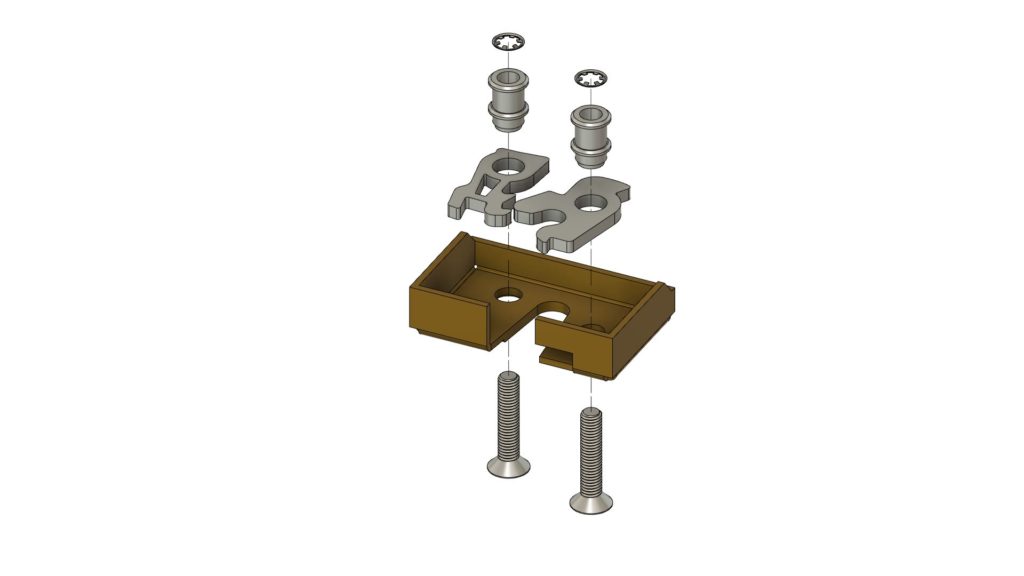

When GoWesty decides that making a new part is necessary, the team turns to Fusion 360 for their CAD/CAM software needs during the product development cycle. “When we design a part ourselves, or if we’re integrating an off-the-shelf part into a full assembly, we’re modeling in Fusion 360,” says Klein. “Fusion 360 allows us to iterate as many times as needed to come up with the best solution.”

Many people don’t realize that GoWesty is a small team. Hardoin notes that it is important for his teammates and him to have access to an affordable CAD/CAM software that meets their needs. “We need 3D modeling software that hits across the board and is still affordable for us. Fusion 360 has been a solid CAD workspace that allows us to do all the design work we need and then easily send our designs to our vendors for manufacturing.”

“The way Fusion 360 manages individual projects works well for us because we’re typically working on one part at a time instead of massive system assemblies,” Hardoin continues. “It’s really handy to be able to work on dozens and dozens of projects independently on the cloud and not have to worry as much about file organization. Then there are the little things like being able to pull master parts into assemblies, the intuitive sheet metal software, and being able to switch between units. We’re working on European vans but are an American company that works with both American and overseas manufacturers, so being able to switch between units is big for us.”

What’s next for the GoWesty team? Hardoin and Klein are eager to get back into the swing of throwing events and interacting with the #vanlife community face-to-face, but in the meantime, they will continue to speak with customers and help them find solutions for their vans online.

Interested in the Fusion 360 tools Hardoin and Klein mentioned, including the sheet metal software and ability to switch between units? Try them out for yourself by downloading Fusion 360 today.