3D printing at home has never been more accessible, leading many hobbyists and engineers to build a convenient home setup. Learn more about building your own 3D printing home setup in this comprehensive guide.

3D printing has come a long way since its inception — what was once a dream for most has quickly become a hobby anybody can pick up. Fifteen years ago, the high cost of 3D printers made them out of reach for the average consumer, and the software used to operate them was extremely complex.

Now, 3D printing doesn’t have to be limited to the machine shop. Printers and materials are more affordable than ever and thus are quickly becoming another home appliance. You can even purchase affordable 3D printers at home appliance stores, depending on machine specifications and capabilities.

Advantages of 3D Printing at Home

To the average consumer, buying a 3D printer for the homestead might be a frivolous investment; in many cases, that is true. However, for imaginative designers seeking new ways to create, additive manufacturing can become a newfound hobby. However, it’s not just hobbyists who benefit from 3D printing at home. With the recent uptick in remote/hybrid positions, some engineers may find working from home more beneficial to their lifestyle. While engineers might not be able to bring their industrial-grade 3D printer home, they can utilize a smaller 3D printer.

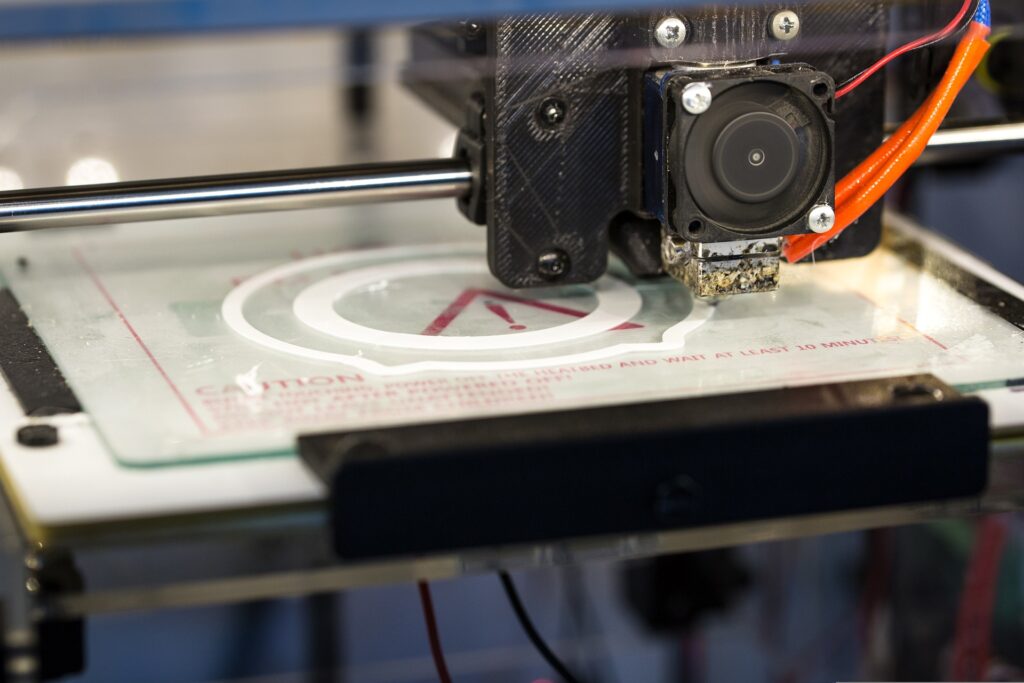

3D printing, simply put, creates a solid out of a liquid (in many cases, melted plastic). The process allows for a lot of creativity, and the materials are affordable — helpful for freelance designers or designers who work remotely.

Engineers can use an at-home 3D printer to test prototype functionality and filament using the rapid prototyping process. Granted, they can’t print an entire product at a one-to-one scale, but being able to see, feel, and manipulate a prototype is just as beneficial to the success of a product.

Rapid Prototyping

Rapid prototyping is a method of creating iterations of a product during the early stages of industrial design. Rapid prototyping allows designers to quickly see the functionality of a project, test tolerances, and effectiveness, and compare variations to other design iterations. On the other hand, traditional prototyping takes a lot more time and materials. Engineers can rapidly prototype a product part using their at-home 3D printer to get hands-on testing without needing to be in the office. The design project can proceed as scheduled, and the final iteration can be manufactured before the deadline.

Where to Buy Affordable 3D Printers and Services

At-home 3D printing is only one 3D printer away from becoming a reality. However, purchasing a quality printer from a trusted source is important to ensure successful outcomes. Companies like Xometry and Ultimaker make 3D printing more accessible.

Ultimaker has a variety of 3D printers available for purchase. It also has a user-friendly website that helps designers determine which type of printer to buy. Ultimaker also provides bundle options to get the printer, software, and materials in one order.

However, for those not yet ready to commit to bringing a 3D printer home, Xometry provides various printing services for essentially any project. Designers can also upload a 3D model to Xometry’s website for an instant quote.

Enhance 3D Printing with Fusion 360

Experienced 3D printers can benefit from upgrading their computer-aided design (CAD) software. Autodesk Fusion 360 provides an easy-to-use integrated platform with various apps that maximize 3D printing capabilities, including a post configurator, an additive assistant, and more.

Download Fusion 360 today to streamline your 3D printing projects and simplify additive manufacturing at home!