This post is also available in: Deutsch (German)

A behind-the-scenes look at how Guinn Partners has launched over 50 consumer products, including one that has surpassed $75 million in sales, using Autodesk Fusion.

Founded in 2017 by serial entrepreneur Colin Guinn with partners Oren Schauble and Craig Nehrkorn, Guinn Partners isn’t focused solely on engineering or design. They offer full, end-to-end services for consumer product development, and they can work with just about anyone.

“We interface with everyone, from dreamers to inventors, startups, and large corporations,” says Eric Davis, director of product, Guinn Partners. “It doesn’t matter where anyone is in their product development cycle—whether it’s just an idea scribbled down on a napkin or almost fully complete and ready for mass production and sales and marketing, Guinn Partners specializes in developing products that are both very profitable for our clients and optimized for a greater user experience to give it the greatest chance in the market.”

Over the past six years, Guinn Partners has helped to launch over 50 projects. From one-off functional prototypes to consumer electronics, robotics, and more, the firm does it all with a rapid iteration process. The company designed and launched the toy company Gel Blaster, which reached $75 million in sales by its third year in business. They’ve also worked with LIFT Aircraft and the development of personal aviation. From the beginning, they’ve used Autodesk Fusion to power their growth and bring product visions to life.

An inside look at Guinn Partners’s consumer product development process

A good majority of Guinn Partners’s projects start in the concept phase—no collateral, no CAD, and not even a requirements or definition document. “The customers want to see us build this crazy, never-before-done idea and bring it into the physical world,” says Mitchell Richburg, mechanical engineer, Guinn Partners.

Guinn Partners helps their entrepreneurial customers work within tight timelines and budgets. During a kick-off meeting, a project manager, technical lead, engineers, and a product manager are determined along with the scope.

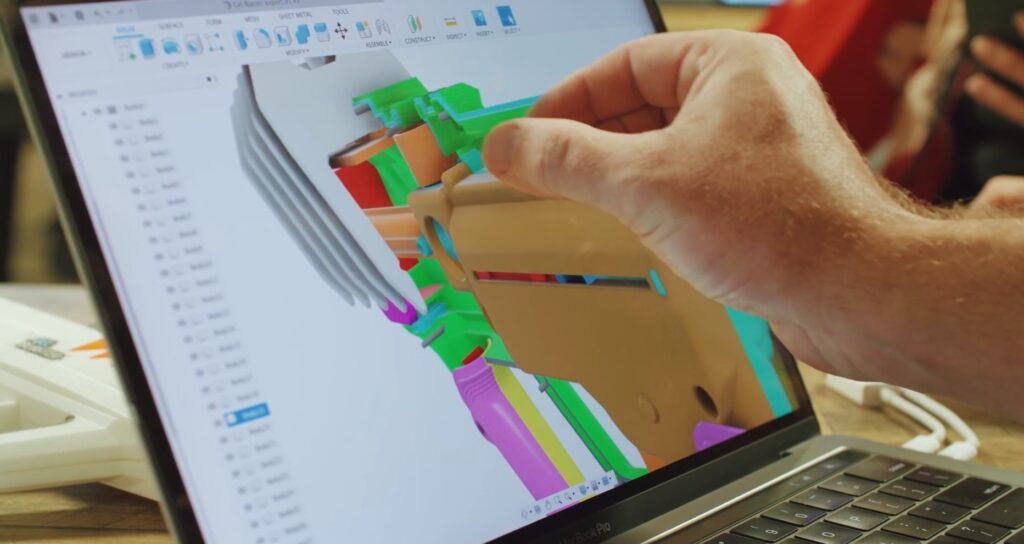

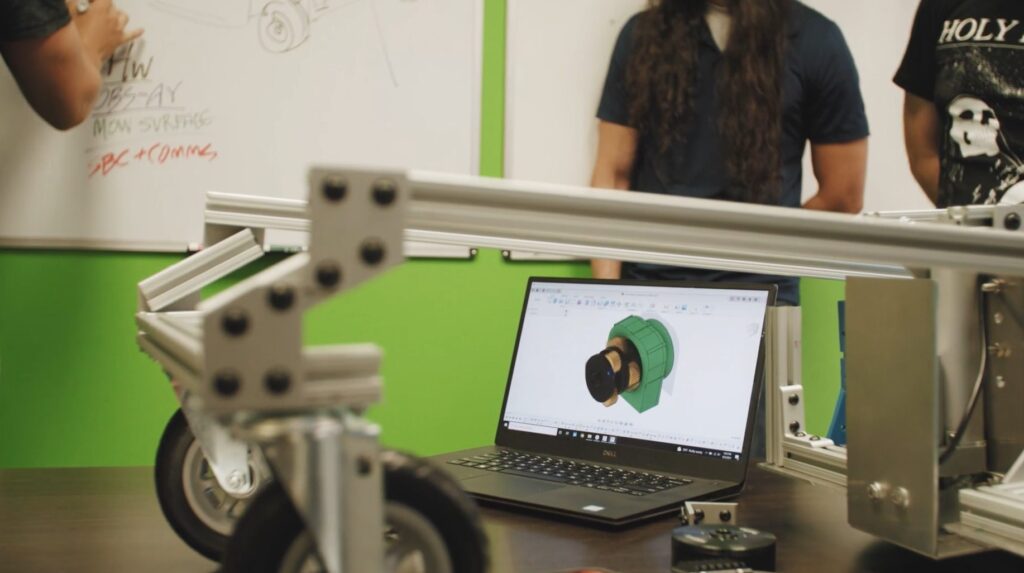

With Fusion, the team immediately moves into mechanical and/or electronics design and integration to iterate and produce prototypes quickly. Along with a 5-axis CNC machine, laser bed, and water jet for more complex jobs, the shop is set up with around 15 3D printers at any given time.

“We may have a team of five or six engineers working on up to 12 projects simultaneously,” says Nicholas LaMour, department head and mechanical engineer at Guinn Partners. “The ability to switch hats and manage all of that seamlessly on a cloud-based platform is very useful to us. We may also be in different locations, whether it’s at the office or with a customer. The ability to just pick up your workstation and run with Autodesk Fusion while still maintaining that collaborative nature—particularly on the mechanical side—is remarkably helpful.”

“Designing on the fly” with Autodesk Fusion

According to LaMour, Fusion lends itself towards essentially “designing on the fly.” “A lot of what we do has never been done before,” he says. “We’re not iterating on something that already exists and looking for a 2% improvement. Not being tied down to have a fully parameterized model and all the documentation structure in place is something that we really enjoy about Fusion.”

The team performs rapid prototyping to produce and learn as much as possible, iterate, and then do it all over again. Often, they will complete 4-6 prototypes for a single project.

“The thing I enjoy most about Fusion is that it actually lends itself very well to what we specialize in, which is iterative development,” LaMour says. “The file management system, the security, the ability to pass files with ease between teammates while still maintaining control is very, very convenient.”

“I really like how we can use Autodesk Fusion for sharing. It’s super easy to collaborate, and we can give each other the help we need. That kind of collaboration handoff is how we can move so fast and not get stuck in the design structure or file management.”

—Mitchell Richburg, mechanical engineer, Guinn Partners

File management and revision history in Fusion are critical to their success with multiple projects, engineers, and stakeholders. “I don’t have to worry about sending my co-workers a messed-up file that they can’t open properly,” Richburg says. “If I ever received one more ‘reference files are missing’ code error in Solidworks, I’d lose it. With Fusion, I can just say ‘Oh, hey, go look in this project folder and work on revision two.’ It’s that easy.”