This post is also available in: Italiano (Italian) Deutsch (German)

Habitat for Humanity and PERI 3D Construction discuss the process of building the organization’s first 3D printed home, including how Autodesk Fusion 360 played an important role.

Earlier this year, Habitat for Humanity took its mission to help people in local communities worldwide to build or improve “a place they can call home” a step further by introducing its first 3D printed home. The home is a single-family, three-bedroom, two-bath structure measuring 1,738 square feet of livable space, built in collaboration with PERI 3D Construction and Candelaria Design Associates.

This marks the first-ever 3D printed home built by the nonprofit organization. At first glance, the house looks completely normal. You wouldn’t be able to tell that the process involved additive manufacturing! However, 70 – 80% of the home is 3D printed using concrete. The house is not only a first for the organization but also a step forward in the housing industry — just imagine a future where affordable housing was more accessible thanks to 3D printing.

“This is really a moonshot opportunity for Habitat for Humanity Central Arizona,” says Jason Barlow, president and CEO, Habitat for Humanity Central Arizona. “When we consider the housing issues facing Arizona, the need for affordable homeownership solutions becomes clear. If we can deliver decent, affordable, more energy-efficient homes at less cost, in less time, and with less waste, we think that could be a real game-changer. Think of the implications.”

A new workflow: from design to 3D print

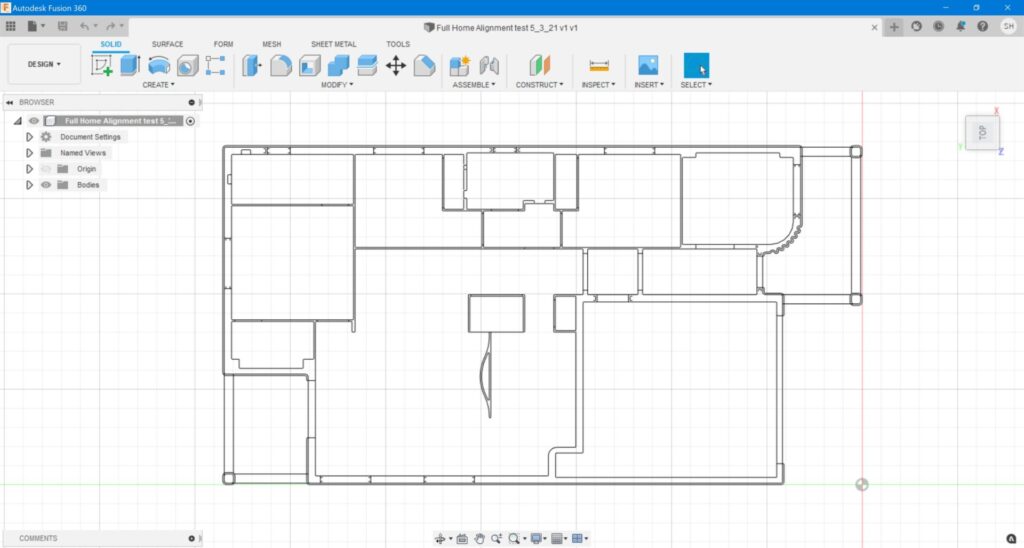

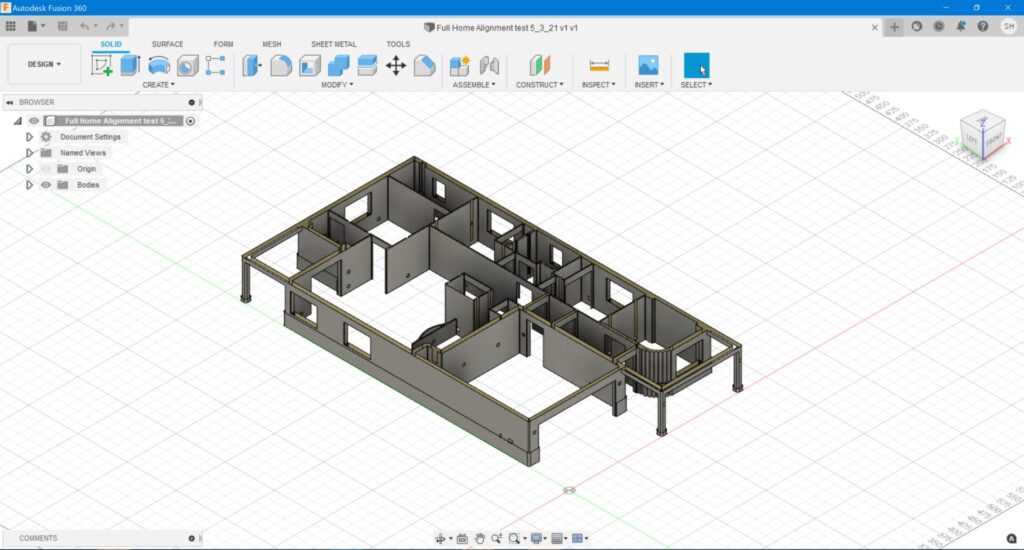

Candelaria Design Associates’ team director and project manager Damon Wake started with a previously permitted, standard habitat plan for a wood-frame house designed in AutoCAD. The team then exported the file as a STEP file from AutoCAD to Autodesk Fusion 360 for further design work.

“You have to eliminate 99% of the information that you’ve drawn in your architectural plans in order to make a print file that tells the print head where to go with the concrete,” Wake explains. “We created the CAD file with a continuous polyline. That was brought into Fusion 360 to turn it all into surfaces and create cutouts where the print head would stop and start for doors or windows.”

Samuel Hager, application engineer at PERI 3D Construction, then “sliced” the 2D centerline drawing in Fusion 360, enhanced the design, and optimized it for the COBOD BOD 2 printer. “The printer is essentially a very large version of a 3D printer—but instead of using melted plastic, we’re using wet concrete and stacking it,” Hager explains.

The printer only recognizes certain file types that Fusion 360 can export, so it was critical to use Fusion 360 for this project. Each of the slices in Fusion 360 represents a layer for printing the concrete, so the printer knew to follow a specific pathway as it printed.

3D printed homes: benefits and opportunities

The home’s concrete foundation and walls took 42 hours to 3D print. From there, the rest of the house was ready for the traditional construction process.

The project revealed how a home’s structure could be constructed with less time and resources than a full traditional build process. PERI 3D Construction estimates if a printer is on-site, a house can be 3D printed and removed within a week. This process also enabled the team to maximize volunteer time and energy.

“The nice thing is you only need two skilled operators and maybe one other construction helper that doesn’t necessarily know much about 3D printing, but they are there to lend a hand,” Hager says. “With a team of three, you’re able to do the work of an entire team of framers.”

“This could be a game-changer for affordable housing—and any housing—if we could significantly reduce the cost and time of construction,” Barlow says. “Where this will become more affordable to us is when we can print five or so two-story townhomes attached in a row at one time.”

A 3D printing learning experience

As 3D-printed homes and structures gain momentum, Hager sees Fusion 360 as an invaluable and integral part of the process. The best part? Anyone curious about this process can start small.

“You can pick up Fusion 360 very quickly and get up to speed with all the tutorials,” Hager says. “Start dipping your toes into it. Pick up a $200 printer, download a free license, and try to 3D print something small. It’s a nice introduction to the fabrication side and really understanding how it works.”

Learn more about this project on Redshift and Australian Manufacturing.

Ready to start your 3D printing journey with Autodesk Fusion 360?