This post is also available in: Français (French) Italiano (Italian) Deutsch (German) 日本語 (Japanese)

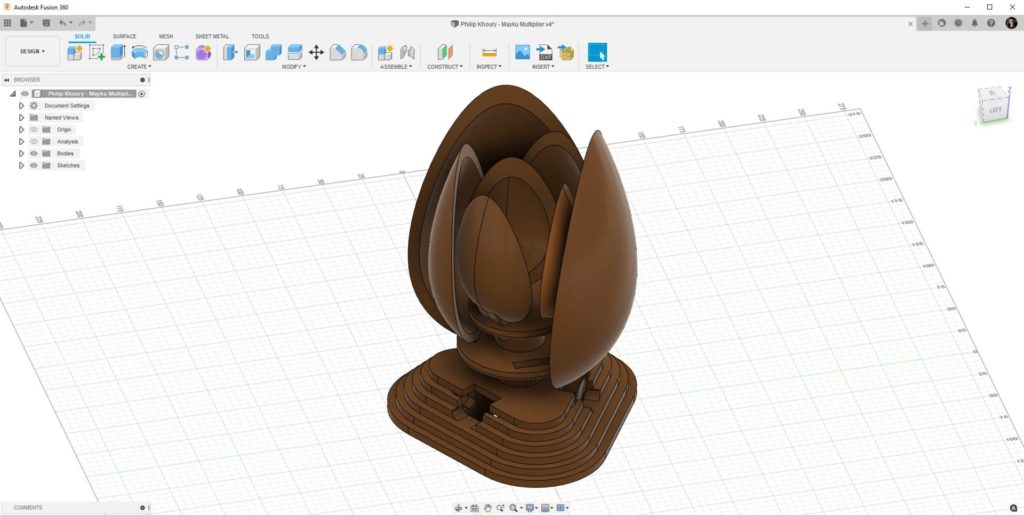

Harrods chocolatier, Philip Khoury, collaborated with Mayku to design chocolate magnolia blooms with Fusion 360 and the Mayku Multiplier.

To put it simply, the Harrods Food Halls in London are iconic. They’re a foodie’s feast for the senses—whether it’s the exotic fruits, a vast variety of artisanal cheeses, freshly baked bread and pastries, steak dry-aged to order, custom-blended tea, or delectable ready-to-eat deli items like truffle mac and cheese.

Pushing the Limits of Luxury

The Chocolate Hall is arguably the landmark experience in the Food Halls, and the Chocolaterie features chocolates created on site. Philip Khoury is a pastry chef and chocolatier at Harrods, and he’s constantly pushing the boundaries of creativity in his work.

“Harrods is all about the art of the possible and stretching the limits of luxury,” Khoury says. “For us, that’s all about bespoke creations.”

Creating a one-of-a-kind chocolate experience requires a recipe with more than a dash of technology nowadays. Chocolate molds are vital to the process, but they are expensive and time-consuming to produce. “A custom mold can cost anywhere from two to three or 4,000 pounds to start, and your lead time for development can be anywhere from eight to 12 weeks,” Khoury says. “It’s kind of something left for the big projects where there’s some big budget. Otherwise, it’s a no-go zone.”

Khoury began working with the team at Mayku to see if custom chocolate molds could be created much more quickly and for less cost. Mayku is building a series of compact machines that are simple enough for anyone to take control of their production—whether it’s design and manufacturing companies, craft businesses, or, yes, chocolatiers.

Designing a Chocolate Magnolia Blossom

Khoury’s inspiration can happen anywhere—even during a simple stroll. “I was walking down the street in spring, and I saw all the magnolias blooming,” Khoury says. “I just thought, ‘How cool would it be to make a blooming chocolate flower that opened up?’ A few different layers that could be a centerpiece at a dinner party that everyone can pull apart and enjoy.”

Agustín Arroyo is a Lead Creator at Mayku. He started working with Khoury to help create the chocolate magnolia blossom with Fusion 360 and the new Mayku Multiplier. In addition to Mayku’s professional-grade FormBox machine, the Multiplier will bring pressure forming to the desktop for the first time with a range of materials for precise, long-lasting molds and production parts in minutes.

Typically, Khoury would have to provide a detailed sketch to a mold maker and then wait. But, with that usual process, the urgency to reflect a timely moment would have passed. Plus, Khoury’s design required multiple molds, making it cost-prohibitive as well.

From Sketch to Reality

Arroyo took Khoury’s ideas from paper sketches and immediately began to 3D model different shapes in Fusion 360, preparing renders and 3D printing prototypes. Quickly, a massive, edible magnolia flower with 15 different parts came to life. Arroyo and Khoury went back and forth to refine the design.

“Being able to share a link to the design in a browser with Fusion 360 was incredibly helpful,” Arroyo says. “Philip could open the model and either send me an email or put a note in the 3D model about any changes needed. He knows how the material behaves, and chocolate can be quite unique.”

“At one point in the prototyping process, we realized the flower would work with 3D printed parts,” he continues. “But when made with chocolate, it wouldn’t open up because the tolerances were too small. With Fusion 360 and parametric modeling, we were able to change and fix that in just three different clicks.”

Opening up to Technology

For Mayku, democratization is paramount with their products. Khoury estimates the cost of one custom mold is about the same price as the entire machine—not to mention the new freedom with creativity and flexibility. Coupled with the ease-of-use to 3D model with Fusion 360, Arroyo recommends all chocolatiers learn it.

“Implementing these digital fabrication workflows in the kitchen completely change how they work,” Arroyo says. “It gives them freedom, and it saves time. There are no downsides to this process.”

In fact, Khoury is doing just that and taking up Fusion 360 on his own.

“After working with Agustín and seeing Fusion 360, I’m now using it to design molds that I create with Mayku FormBox and 3D print them,” Khoury said. “I worked with some designers at Harrods who used different programs but struggled to get smooth results.

“Fusion 360 has allowed me to do simpler shapes, and I’ve found it easier and more efficient,” he continues. “Chocolate molds have some specific requirements—and whatever you’re molding needs to be able to come out of the mold. Fusion 360 helps me make sure that happens!”

Watch Khoury and Arroyo bring the chocolate magnolia blossoms to life in the video below: