Within the machining industry, there can sometimes be confusion between the terms high feed rate and rapid feed rate. This article discusses the difference between the two and the advantages and disadvantages of each.

What is rapid feed rate?

Rapid feed rate typically refers to the maximum feed rate achievable by the CNC machine. The rapid feed rate control on the machine will control the feed rate. The benefit of rapid feed is the speed of travel. Our manufacturing process can have shorter cycle times if we can get to the required destination in a shorter period.

The possible disadvantages of rapid feed are unpredictable dogleg moves. This occurs when different axis have different maximum feed rates because each axis can get to its required destination before the other. Ultimately, some controls automatically compensate for the dogleg motion so that it doesn’t occur. Others will move all axes as fast as possible. Occasionally, this is even an option set on the CNC control.

What is high feed rate?

A high feed rate generally refers to a controlled higher feed rate that activates G01 (G01 is a high feed move, while G0 is a rapid feed move). You can control feed rate within CAD software. The benefit to using high feed is the reduction in feed rate can avoid unpredictable, possibly dangerous, dogleg moves. Alternatively, the disadvantage is that cycle times can be less efficient due to the speed reduction of the traveling axis.

Finding feed rate settings in Fusion 360

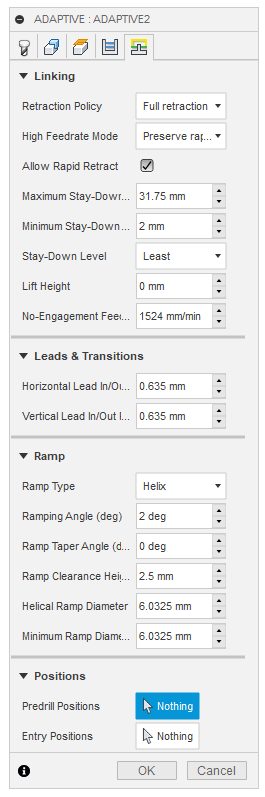

Within Autodesk Fusion 360, you can control what kind of linking move is outputted within the Linking tab. Within the high feed rate drop-down, under linking, there are six options, including:

- Preserve rapid movement – All rapid movements are preserved

- Preserve axial and radial rapid movement – Rapid movements moving only horizontally or vertically are output as true rapids

- Preserve axial rapid movement – Only rapid movements moving vertically

- Preserve radial rapid movement – Only rapid movements moving horizontally

- Preserve single axis rapid movement – Only rapid movements moving in one axis (X, Y, or Z)

- Always use high feed – Outputs rapid movements as (high feed moves) G01 moves instead of rapid movements (G0)

Default settings

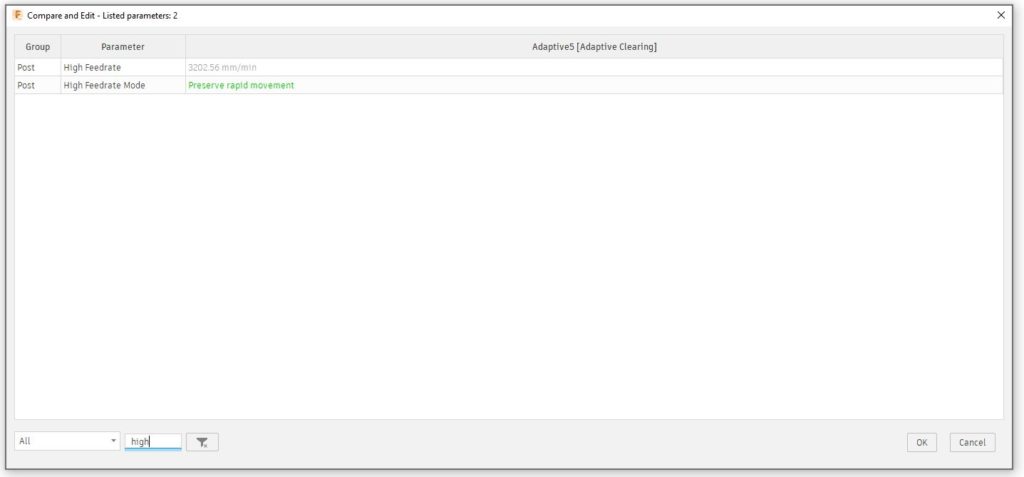

The default high feed rate mode in Fusion 360 is Preserve Rapid Movements. This may be desirable for you, but if you’d like to change the default selection, you can follow the below steps:

- Right-click on a toolpath

- Compare and edit

- Search high feedrate mode

- Activate the drop-down

- Make a selection

- Right-click the box

- Save as user default

Now you know more about the differences between rapid feed rate and high feed rate. Ready to machine your next idea using an integrated CAD/CAM solution? Try Fusion 360 for free today: