AI in manufacturing is improving product quality and efficiency through data analysis, design optimization, supply chain management, and process automation. Autodesk Fusion exemplifies this integration, offering AI-driven generative design, CAM automation, and future automated drawing capabilities, ushering in a new era in manufacturing.

The manufacturing sector is no exception to the artificial intelligence (AI) technology revolutionizing most fields today. AI is more than a futuristic concept. It is now a practical tool for enhancing product quality and efficiency in manufacturing. For product development professionals, it’s crucial to understand the industry impact of AI and how it’s transforming product design, development, and market introduction.

Let’s take a closer look at how AI enhances product quality, and how Autodesk Fusion supports this powerful technology.

The role of AI in manufacturing

AI’s role in manufacturing is multifaceted, addressing various challenges and opportunities in the industry.

A primary benefit of AI is its ability to analyze large datasets quickly and accurately. In the context of manufacturing, this capability is crucial for identifying trends, predicting outcomes, and making data-driven decisions. AI plays an important role in making manufacturing processes streamlined with its ability to catch errors that are often overlooked by humans. For example, computer vision AI systems can detect minute defects in materials or inconsistencies in production processes. AI’s ability to enhance these processes results in higher quality control, sustainability, and process optimization across the manufacturing line.

The impact of AI

Furthermore, AI is also making significant impacts within design and development areas. AI-powered tools can simulate and test various design scenarios in a fraction of the time it would take humans to do manually. An example might be using AI to simulate the stress and strain on various materials, helping designers select the most durable choices for their products. By identifying potential issues early in the development cycle, AI helps to accelerate the design process and improve final product quality.

Moreover, AI facilitates enhanced supply chain management. AI can predict demand, optimize inventory levels, and identify potential supply chain disruptions. As a result, these systems may be able to anticipate shifts in consumer demand and help manufacturing lines adjust their output accordingly. The integration of AI enables a proactive approach to supply chain management. Ensuring that manufacturing processes are not halted due to unforeseen circumstances, thereby maintaining product quality and delivery timelines.

Ultimately, AI optimizes the manufacturing process from start to finish. With the integration of AI in robotics and automation, manufacturing plants are becoming more efficient and less prone to errors. AI algorithms can control and optimize manufacturing equipment, supporting consistent and high-quality production outputs.

Autodesk Fusion and AI integration

Autodesk Fusion serves as a prime example of how AI integration can elevate manufacturing processes. Fusion leverages AI in several key areas:

Generative Design

Fusion has integrated generative design technology for manufacturing, using AI to generate thousands of design solutions for a defined problem. This technology allows designers and engineers to quickly analyze and choose the best design alternatives.

Automated Modeling

At the beginning of the design process, automated modeling in Fusion enables rapid design exploration, offering numerous editable design alternatives and the ability to uncover new possibilities for approaching design problems.

CAM Automation

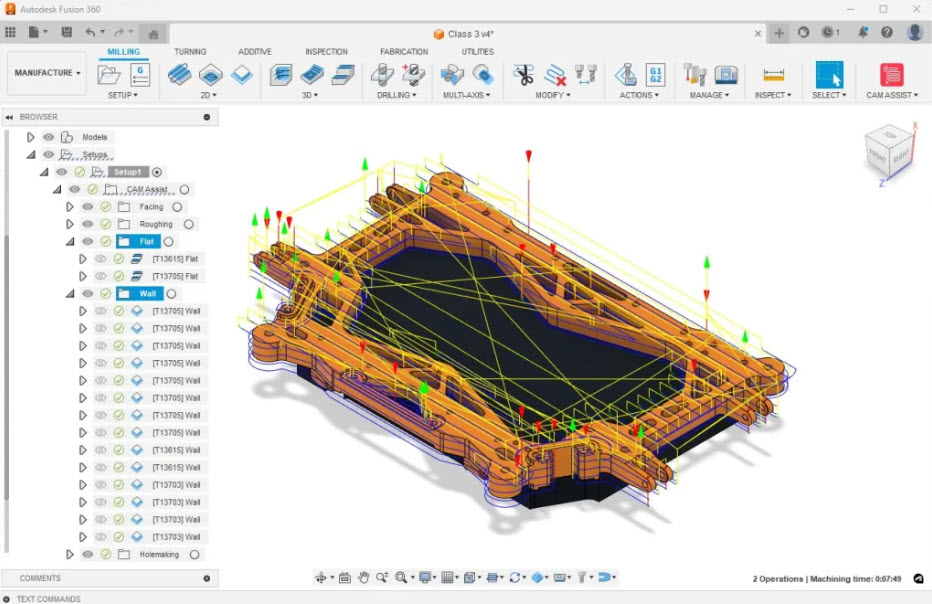

The CloudNC CAM Assist Automation Add-in for Fusion translates 3D models into machining strategies in seconds. Thus, significantly reducing the time required for CAM programming tasks.

Automated Drawings

Scheduled for future release, automated drawings will convert 3D models into fully dimensioned drawings with a simple click, streamlining the documentation process.

Reimaging Product Quality in Manufacturing

As consumers continue to demand higher-quality products at lower prices, the need for technological innovation is clear. With the integration of AI, manufacturing is undergoing a significant leap in how products are designed, developed, and produced—driving lower costs and better yields across the board. Tools like Fusion 360 allow manufacturers to fully harness the power of AI in their design and manufacturing workflows. Thankfully, Autodesk is helping manufacturers achieve the promise of enhanced product quality, efficiency, and sustainability for a better future.