Designing a product can be a difficult process depending on time constraints, available materials, and other manufacturing limitations. However, there are also executable procedures that aid the design process, such as reverse engineering. Reverse engineering allows engineers to recreate old electronic components like PCBs (printed circuit boards), transfer outdated 2D drawings to digital 3D AR (augmented reality) environments, and bridge data between operating systems for compatibility.

What is Reverse Engineering?

Reverse engineering is exactly how it sounds: engineering in reverse. Engineers can and will, if necessary, deconstruct a machine or software to extract vital design information; in other words, this process strips the larger product into smaller components to determine how a part was designed and implemented. The ultimate goal is to recreate and understand the original part design or function.

For example, an English student is taught to deconstruct a sentence and identify individual components — subject, verb, preposition, noun, etc. — to understand how to write clearly and effectively. Another example would be an automotive mechanic who has decided to restore a car from the mid-1900s. The mechanic could reverse engineer the existing engine or chassis to recreate missing or hard-to-find components.

Reverse Engineering Applications

So what are some reverse engineering process implementations in the design world?

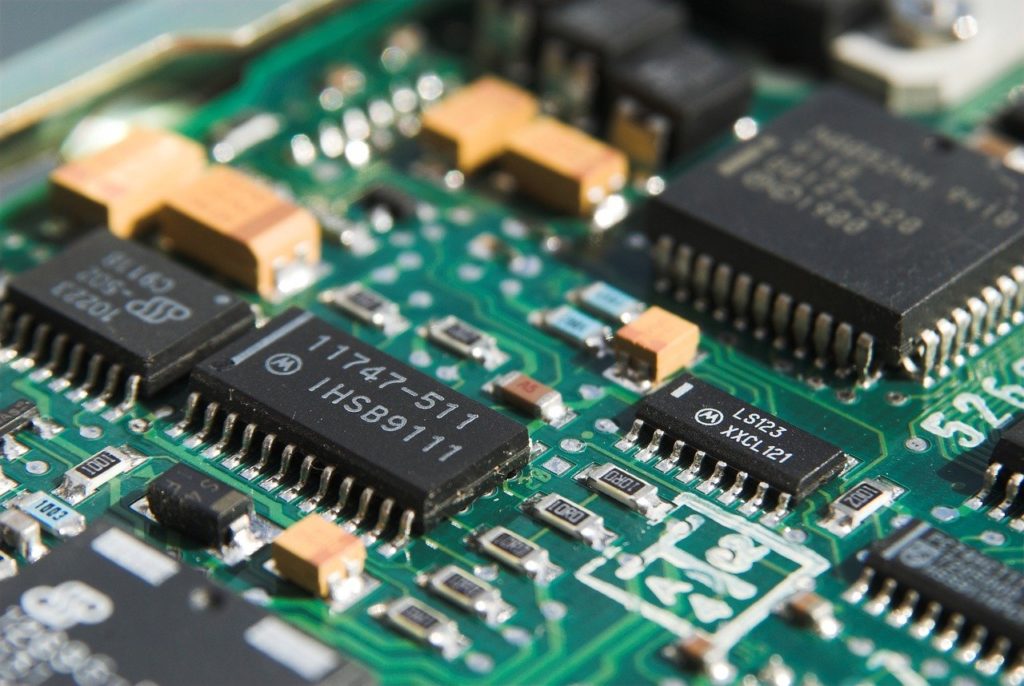

For one, engineers can reverse engineer and resurrect old or forgotten PCB designs. Engineers and designers sometimes receive PCBs from manufacturers that have gone out of business or no longer manufacture that specific product. In these cases, depending on legal constraints outlined in business contracts or federal law.

In other cases, old computer components may have been lost in the sands of time and technological advancement but still hold a particular source code essential to another product’s success. Reverse engineering may be the only avenue for obtaining an original PCB design.

This leads to the second application: augmented reality. When an engineer finally discovers an older design, they may find themselves staring at a two-dimensional sketch. Thanks to technological advancements in the last decade, engineers can now transfer 2D designs into 3D augmentations.

Augmented reality is a digital platform used to view three-dimensional renderings in real-life environments. Using an iPhone, an engineer can access a USDZ file — a file format created by Pixar and Apple that displays AR content on iOS devices — which then displays a 3D design onto a real-life environment via the phone’s camera. The engineer can manipulate the 3D design on the phone’s screen using their fingers or by walking the phone around the central design/focal point. AR is a perfect environment to check product functionality. Design software like Fusion 360 allows you to take models directly from CAD and view them in AR through your mobile device.

Along with the 2D to 3D transition is the digitization of physical data. Reverse engineering lends a helping hand to software optimization by allowing for data transfer from physical to digital and then across platforms. Engineering firms can resuscitate software code, physical components, or forgotten designs simply by reverse engineering.

What is the Legality of Reverse Engineering?

While reverse engineering is legal, there are federal laws and corporate contracts that prevent outright product duplication. Here are some basic copyright law and intellectual property references for further study:

- The Electronic Communications Privacy Act

- The Anti-Circumvention Provisions of the Digital Millennium Copyright Act (DMCA)

- End User License Agreement (EULA)

- Terms of Service (TOS)

- Terms of Use (TOU)

- Non-Disclosure Agreement (NDA)

- Developer Agreement

- Trade Secret Law

As with any business practice, engineers should become familiar with local and/or international laws and regulations. Otherwise, reverse engineering can be a useful and effective tool for engineers in all genres of design research.

Try Fusion 360 to unlock the ability to transfer old 2D relics to 3D design. With an integrated CAD (computer-aided design) and CAM (computer-aided manufacturing) software, Fusion 360 harnesses reverse engineering and additive manufacturing processes all in one place.