Learn what exactly is a resistor, how does it work, and how do you choose the right one for your first PCB design?

Are you planning to start on your first PCB design? There are so many types of components that you’ll end up using, but none can beat the infamous of them all – the simple resistor. If you have ever looked at a circuit board, you’ll find resistors are all over the place, controlling the current flow and making those LEDs light up. But what exactly is a resistor, how does it work, and how in the world do you choose the right one for your first PCB design?

Fear not, we have you covered with everything you might need to know.

So…What is a Resistor?

Resistors are one of several passive electrical components, and what they do is relatively simple yet vital – creating resistance in the flow of an electric current. Have you ever seen a LED light up? That was made possible thanks to the trusty resistor. By placing a resistor behind a LED in a circuit, you get all of the brilliant lights without anything burning out!

The value of a resistor is its resistance, measured in Ohms (Ω). If you have ever taken a basic electronics course, then your instructor likely drilled Ohm’s Law into your head. You will use Ohm’s Law time and time again when dealing with resistors. More to come on this:

Finding a resistor symbol on a schematic is easy. The international symbol is a standard rectangular shape, but the US standard has the zigzag line that makes it easy to identify. Regardless of the form, both styles have a set of terminals connecting the ends.

What Are the Different Types of Resistors?

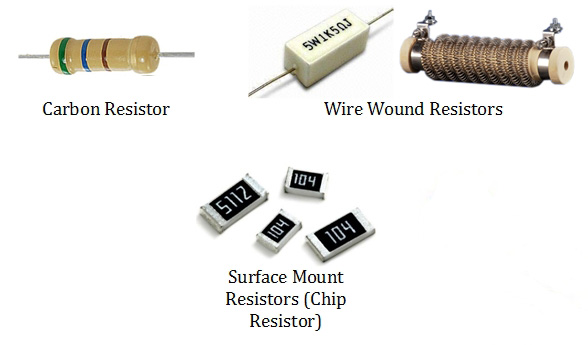

There’s a ton of resistors floating about that are divided into two categories – construction type and resistance material. Let’s cover both:

Construction Type

- Fixed Resistors – As the name implies, these resistors have a fixed-resistance and tolerance regardless of any changes in external factors like temperature, light, etc.

- Variable Resistors – These parts have a modifiable resistance. The potentiometer is a great example, which has a dial that can be turned to ramp up or down the resistance. Other variable resistors include the trimpot and rheostat.

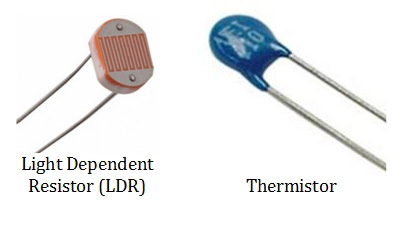

- Physical Quality Resistors – These resistors are like chameleons and can change their resistance based on a variety of physical properties, including temperature, light levels, and even magnetic fields. Physical quality resistors include the thermistor, photoresistor, varistor, and magneto-resistor.

Resistance Material

Resistors can also be broken down into the actual material they are made from, which has a massive effect on how they resist current. These materials include:

- Carbon composition

- Carbon film

- Metal film

- Thick and thin film

- Foil

- Wire Wound

Carbon composition is an older technique that has been around for a while and produces a resistor with a low degree of precision. You’ll still find these for use in applications where high energy pulses occur.

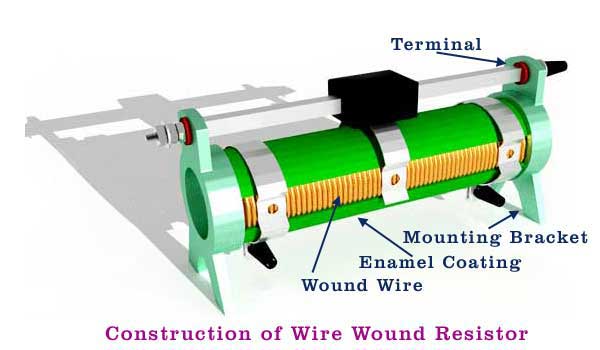

Of all the resistor material types, wire wounds are the oldest of them all, and you’ll still find these in use when you need precise resistance for high power applications. These ancient resistors are widely known for being reliable, even at low resistance values.

Today, metal and metal oxide resistors are the most widely used, and are better for providing a stable tolerance and resistance, while also being less influenced by changes in temperature.

How Do You Use Resistors?

You’ll find resistors being utilized in many applications beyond just resisting current. Other applications include dividing voltage, generating heat, matching and loading circuits, controlling gain, and fixing time constraints. In more practical applications, you’ll find large resistors being used to power electric brakes in trains, which helps to release all of the stored kinetic energy.

Here are some other cool applications that the versatile resistor is used for:

- Measuring electrical current – You can measure the voltage drop across a precision resistor that has a known resistance when it’s connected to a circuit. This is calculated using Ohm’s Law.

- Powering LEDs – Giving a LED too much of a current will burn out that beautiful light. By connecting a resistor behind a LED, you can control how much current the LED receives to keep the light shining.

- Powering blower motors – That ventilation system in your car is being driven by a blower motor, and a special resistor is used to control the speed of the fan. This resistor type is called, not surprisingly, the blower motor resistor!

How do You Measure a Resistor?

The value that you will see time and time again is resistance (R). This value is displayed in different ways, and there are currently two standards for measuring how resistance appears with either color-coded markers or SMD codes.

Color-Coding

You might be familiar with the color-coding system if you have ever tinkered with a breadboard. This technique was invented in the 1920’s, and the resistance and tolerance values are displayed by several colored bands painted on the body of the resistor.

Most of the resistors that you look at will have four colored bands. Here’s how they breakdown:

- The first two bands determine the primary digits of the resistance value.

- The third band determines the multiplying factor, which will give a resistance value.

- And lastly, the fourth band provides you with a tolerance value.

All of the different colors on a resistor correspond to different numbers. You can use a handy resistor color code calculator to quickly determine these values in the future.

SMD Resistors

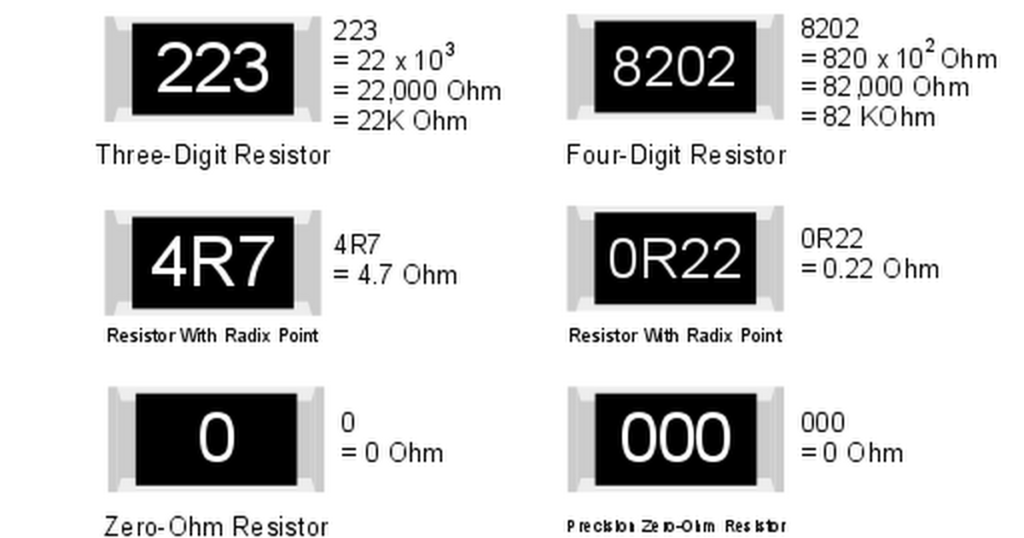

Not every resistor is large enough to be identified by color-coding, especially when using Surface Mount Devices, or SMDs. To compensate for the smaller space, SMD resistors are given a numerical-based code. If you take a look at a modern circuit board, you’ll notice that SMD resistors are also all about the same size. This helps to standardize the manufacturing process with those rapid-fire pick-and-place machines.

How do I Choose the Right Resistor?

Ok, time for the most important part, learning how to figure out precisely what kind of resistor you need for your first PCB design. We have broken this down into three easy steps, which includes:

- Calculating your required resistance

- Calculating your power rating

- And lastly, selecting a resistor based on these two values.

Step 1 – Calculating Your Resistance

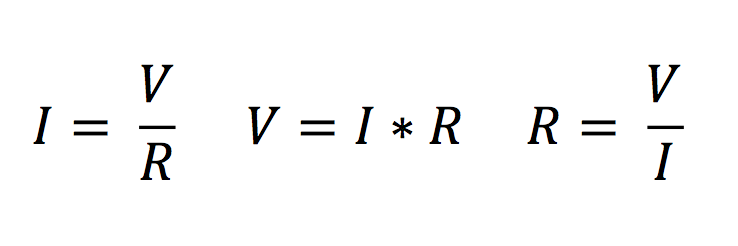

This is where you will use Ohm’s Law to calculate your resistance. You can use one of the standard formulas below when your voltage (V) and current (I) are known.

Step 2 – Calculating Your Power Rating

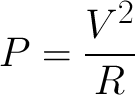

Next, you need to figure out how much power your resistor is going to need to dissipate. This can be calculated with the following formula:

In this formula, P is your power in Watts, V is the voltage drop across the resistor, and R is the resistance of the resistor in Ohms. Here’s a quick example of how this formula would work in action:

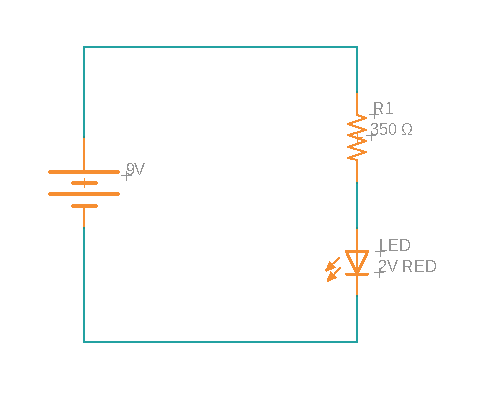

In the circuit above, we have a LED that has a 2V voltage, a resistor with a 350 Ohm (Ω) value, and a power supply giving us 9V. So how much power will dissipate in this resistor? Let’s add it up. We first need to find the voltage drop of the resistor, which is 9V from the battery and 2V from the LED, so:

9V – 2V = 7V

You can then plug in all of this information into your formula:

P = 7V*7V / 350 Ohm = 0.14 Watts

Step 3 – Choosing a Resistor

Now that you have your resistance and power rating values, it’s time to pick an actual resistor from a component distributor. We always recommend sticking with standard resistors that will be carried in stock by every distributor. Staying with standard resistor types will make your life a whole lot easier once it’s time to manufacture. Three dependable component suppliers that you can find some quality parts from include Digikey, Mouser, and Farnell/Newark.

The Resistance is Strong in This One

So there you go, everything you might possibly ever need to know about resistors for your first PCB design project. Resistors have so much versatility, and you’ll find yourself using them time and time again in every electronics project that you complete. The next time you need to choose a resistor, remember the simple three-step process – 1. calculate your resistance, 2. then your power rating, 3. and then find a supplier!

Now, before you run off making your own resistor symbols and footprints in your PCB design software, wouldn’t it just be easier if they were already done for you? They already are! Check out the vast amount of free parts libraries available only in Fusion 360. Try Fusion 360 electronics for free today.